Silver anti-tarnishing agent, silver anti-tarnishing resin composition, silver anti-tarnishing method, and light-emitting diode using same

A technology for light-emitting diodes and resin compositions, applied in chemical instruments and methods, coatings, electrical components, etc., can solve the problems of decreased light reflectivity, disadvantage, high gold economy, etc., achieve excellent durability, and prevent illuminance from decreasing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 3

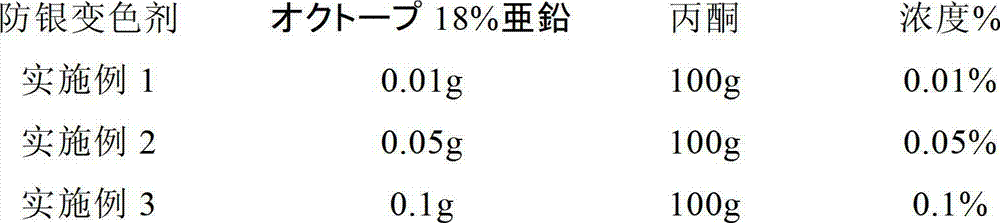

[0140] Examples 1 to 3 specifically show the anti-silver discoloration agent when coating the surface of silver.

[0141] Preparation of anti-silver discoloration agent solution:

[0142] Zinc 2-ethylhexanoate (manufactured by Hope Pharmaceutical Co., Ltd., product name: オクブプ 18% lead) as an active ingredient of the anti-silver discoloration agent was dissolved in acetone at the concentration shown in Table 1 to prepare the present invention. Anti-silver discoloration agent.

[0143] [Table 1]

[0144]

[0145] Fabrication of LEDs:

[0146] The solution of Example 1 was dropped into a surface mount type (hereinafter abbreviated as SMD (Surface Mounted Devices)) light-emitting diode package with an opening of φ5 mm, silver-plated wiring on the lead frame, and a chip with a central emission wavelength of 465 nm. 0.015g (the active ingredient amount is 0.0000015g), and the resulting light-emitting diode is packaged and placed in a drier at 80° C. for 1 hour, making the SMD ...

Embodiment 4 to 12、 comparative example 1、2

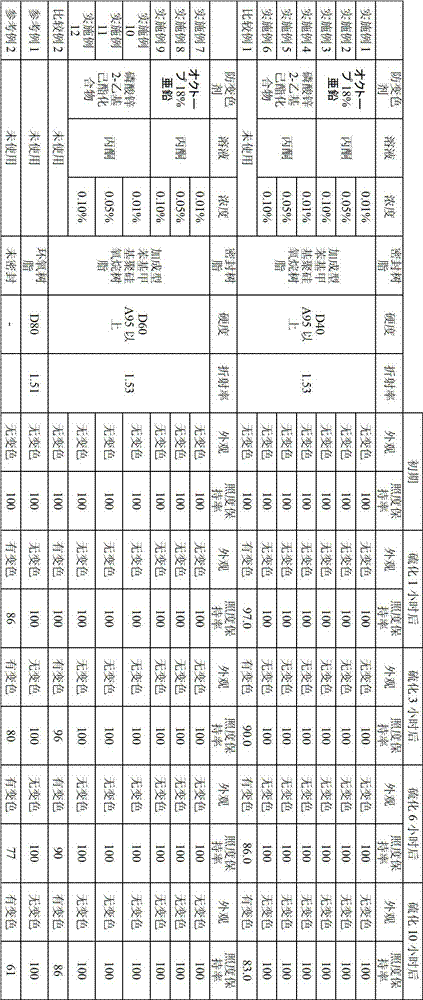

[0161] The same operation as in Example 1 prepares the anti-silver discoloration agent solution of the embodiment 4 to 12 of the composition shown in table 2, and uses this solution, and the same operation as in Example 1 uses sealing resin on the dry film of this anti-silver discoloration agent Sealing is performed to produce light-emitting diodes. In addition, a vulcanization test was carried out in the same manner as in Example 1, and the results are described in Table 2 together with the composition of the silver discoloration preventing agent used. In addition, the test results of Comparative Examples 1 and 2 that did not use the anti-silver discoloration agent of the present invention are also shown in Table 2.

[0162] In addition, the addition reaction type phenylmethylpolysiloxane resin used for sealing in Examples 7 to 12 (the hardness of the D-type durometer after curing is 60) was obtained by mixing the following A liquid and B liquid in a weight ratio It is obtaine...

Embodiment 13、14

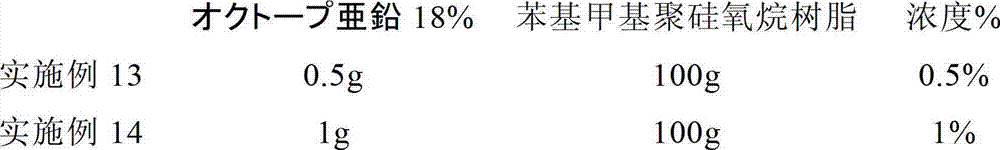

[0169] Next, as embodiment 13,14, prepare the anti-silver discoloration resin composition (a kind of mode of anti-silver discoloration agent of the present invention) containing zinc compound (zinc salt and / or zinc complex) and sealing resin, and use The composition seals light-emitting diodes to study the anti-silver discoloration effect.

[0170] Preparation of anti-silver discoloration resin composition:

[0171] With respect to 100 g of the addition-reaction type phenylmethyl polysiloxane resin having a hardness of 40 on a D-type durometer after curing, which is the same as that used in Example 1, 18% of Okab-Pu-Pb was prepared in advance in Table 3. The indicated concentration was added and mixed to obtain a sealing material, thereby producing a silver discoloration preventing resin composition.

[0172] Addition concentration is the addition ratio with respect to polysiloxane resin.

[0173] [table 3]

[0174]

[0175] Fabrication of LEDs:

[0176] Into a surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com