Water dispersible granules containing dicamba salt and atrazine and method for manufacturing water dispersible granules

A technology of dicamba and dispersible granules, applied in the directions of botanical equipment and methods, herbicides, algicides, biocides, etc., to achieve the effects of reduced dosage, good safety, and easy popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

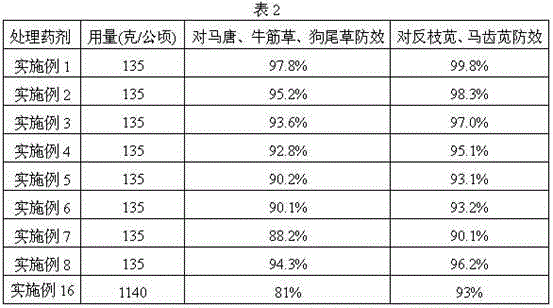

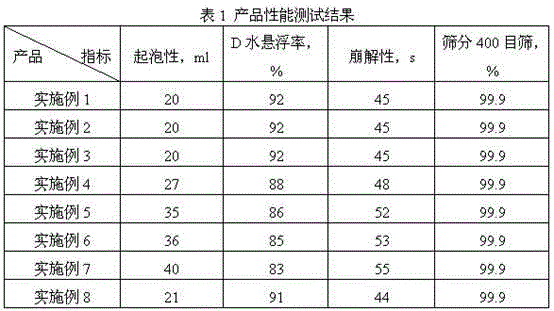

[0032] Example 1 90% dicamba sodium salt and atrazine water dispersible granules

[0033] Wheat grass sodium salt 34%, atrazine 56%, dispersant polycarboxylate sodium salt 1.5%, sodium alkylphenol sulfonate 1%, calcium lignosulfonate 1.5%, wetting agent a-sulfofatty acid methyl ester 0.1 %, sodium a-olefin sulfonate 1.0%, fatty amide N-methyl taurine sodium salt 0.4%, disintegrant potassium dihydrogen phosphate 1.0%, diammonium hydrogen phosphate 0.32%, potassium chloride 0.18%, kaolin supplement 100%, after the mixture is fully mixed and evenly mixed, carry out ultrafine airflow pulverization to obtain 700-mesh fine powder, and then add an appropriate amount of water in the kneader to knead the obtained fine powder. Drying at 65°C in the bed can obtain 90% dicamba salt and atrazine water dispersible granules.

Embodiment 2

[0034] Example 2 70.49% dicamba sodium salt and atrazine water dispersible granules

[0035] Dicamba sodium salt 26.6%, atrazine 43.89%, dispersant polycarboxylate sodium salt 1.5%, sodium alkylphenol sulfonate 1%, calcium lignosulfonate 1.5%, wetting agent a-sulfofatty acid methyl ester 0.1%, sodium a-olefin sulfonate 1.0%, fatty amide N-methyl taurine sodium salt 0.4%, disintegrant potassium dihydrogen phosphate 1.0%, diammonium hydrogen phosphate 0.32%, potassium chloride 0.18%, kaolin Make up 100%, after the mixture is fully mixed and evenly mixed, carry out ultrafine airflow pulverization to obtain a 700-mesh fine powder, and then add an appropriate amount of water in the kneader to knead the obtained fine powder. Dry at 65°C in a chemical bed to obtain 70.49% dicamba salt and atrazine water dispersible granules.

Embodiment 3

[0036] Example 3 10.6% dicamba sodium salt and atrazine water dispersible granules

[0037] Dicamba sodium salt 4%, atrazine 6.6%, dispersant polycarboxylate sodium salt 1.5%, sodium alkyl phenol sulfonate 1%, calcium lignosulfonate 1.5%, wetting agent a-sulfofatty acid methyl ester 0.1%, sodium a-olefin sulfonate 1.0%, fatty amide N-methyl taurine sodium salt 0.4%, disintegrant potassium dihydrogen phosphate 1.0%, diammonium hydrogen phosphate 0.32%, potassium chloride 0.18%, kaolin Make up 100%, after the mixture is fully mixed and evenly mixed, carry out ultrafine airflow pulverization to obtain a 700-mesh fine powder, and then add an appropriate amount of water in the kneader to knead the obtained fine powder. Dry at 65°C in a chemical bed to obtain 10.6% dicamba salt and atrazine water dispersible granules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com