Di-(2-hydroxyl isopropyl) benzene production method

A technology for the production of hydroxyisopropyl, which is applied in the field of di-benzene production, can solve the problems of long process flow and high consumption of public works, and achieve the effects of simplifying the process flow, reducing consumption, and good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

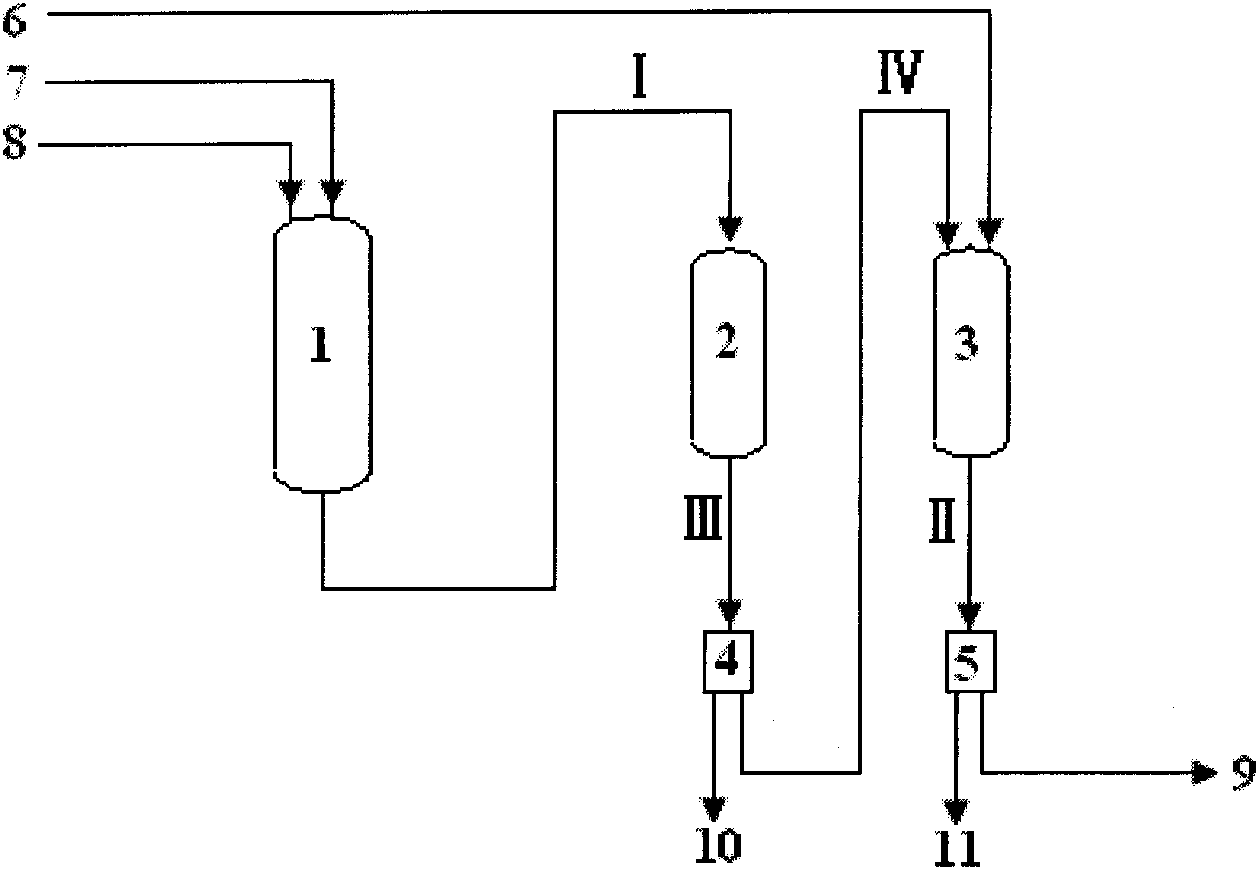

[0017] use figure 1 In the process shown, the stream 8 containing bis-(isopropylhydroperoxide)benzene and the reducing agent 7 enter the reduction reactor 1, where the bis-(isopropylhydroperoxide)benzene and the reducing agent are generated Reducing reaction to obtain stream I. Stream I enters the first crystallization zone 2 and obtains stream III after crystallization. The stream III enters the first separation zone 4, and after centrifugal separation, the first mother liquor 10 and the stream IV are obtained. The stream IV and the solvent 6 enter the second crystallization zone 3, and the stream II is obtained after crystallization. The stream II enters the second separation zone 5, after centrifugal separation, the second mother liquor 11 and the product di-(2-hydroxyisopropyl)benzene 9 are obtained; the first mother liquor 10 and the second mother liquor 11 enter the subsequent process.

[0018] The stream containing bis-(cumyl hydroperoxide) benzene is a dicumyl benzene ...

Embodiment 2

[0022] Same as [Example 1], except that the reducing agent is potassium sulfide, and the weight ratio of bis-(isopropylhydroperoxide)benzene to potassium sulfide is 10:8.

[0023] The purity of the product di-(2-hydroxyisopropyl)benzene 9 is 85.1% by weight.

[0024] The consumption of public works is 39 tons / ton DC of chilled water, 275 tons / ton DC of circulating water, 3.0 tons / ton DC of steam, and 365kWh / ton DC of electricity.

Embodiment 3

[0026] Same as [Example 1], except that in the reduction reactor, the reaction temperature is 120°C and the reaction pressure is 0.7 MPa. The operating pressure of the first crystallization zone is 0.5MPa, and the operating temperature is 60°C. The operating pressure of the second crystallization zone is 0.45MPaG, and the operating temperature is 60℃

[0027] The purity of the product di-(2-hydroxyisopropyl)benzene 9 is 85.1% by weight.

[0028] The consumption of public works is: chilled water consumption is 41 tons / ton DC, circulating water consumption is 287 tons / ton DC, steam consumption is 3.2 tons / ton DC, and electricity consumption is 388kWh / ton DC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com