Method for supercritical CO2 extraction of effective ingredients of Haematococcus pluvialis spore powder

A technology of Haematococcus pluvialis and active ingredients, applied in organic chemistry, bulk chemical production, etc., can solve the problems of failure to comprehensively consider the correlation of various factors, lack of in-depth research on the purification process, and increase the difficulty of astaxanthin extraction, etc. Problems, to achieve the effect of enhancing carrying capacity, improving permeability and diffusion rate, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

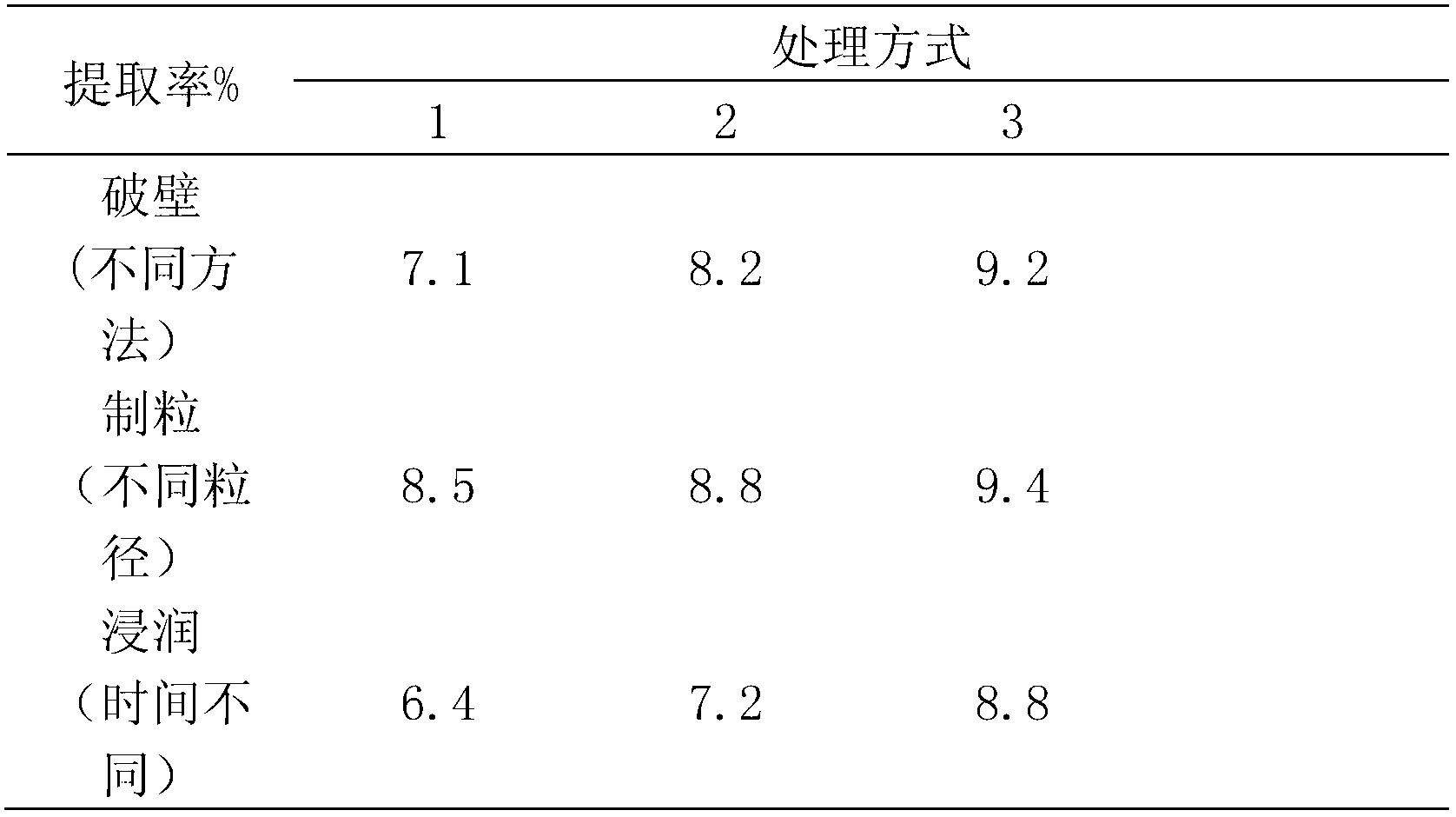

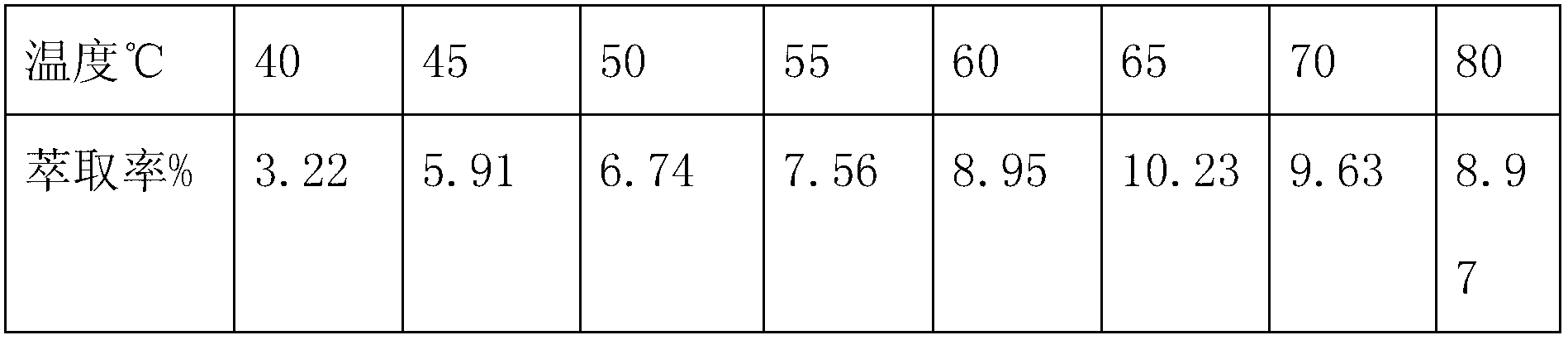

Embodiment 1

[0041] The astaxanthin content weight percent is 1.5% Haematococcus pluvialis spore powder, frozen and crushed with low-temperature liquid nitrogen, the wall-breaking rate is 92%, the particle size is 100 mesh, granulated, and the broken wall of Haematococcus pluvialls The spore powder is subjected to physical characteristics wet granulation with alcohol, the particle size is 14-20 mesh, and then granulated, sieved, infiltrated, and the granules made of Haematococcus pluvialis spore powder are granulated with 95% edible alcohol. Soak, the granule that Haematococcus pluvialis spore powder makes: Edible alcohol=1: 1 is by mass ratio, soaking time is 4 hours; After 1000g glass beads are dried, mix evenly with 4000g Haematococcus pluvialls spore powder granule and carry out The grid filling and filling the kettle, the mixed grid filling adopts manual methods, the filling process should pay attention to the tightness of the material structure, and after the filling is completed, pre...

example 2

[0043] Take Haematococcus Pluvialls spore powder with astaxanthin content of 1.5%, freeze and pulverize the wall with low-temperature liquid nitrogen, the wall-breaking rate is 96%, and the particle size is 400 meshes, granulate, and the Haematococcus pluvialls spore powder after the wall is broken Wet granulation of physical properties by alcohol, granule size 16 mesh, granulation, sieving, infiltration, using edible alcohol with a mass percentage concentration of 95% to soak the granules made of Haematococcus pluvialis spore powder, Pluvialls red balls Granules made from algae spore powder: edible alcohol=1:10 by mass ratio, soaking time is 8 hours. After drying, 1000g of glass beads is mixed with 4000g of Haematococcus pluvialis spore powder particles evenly, and then filled into the kettle by gridding. The mixed gridding filling adopts manual method. Pay attention to the elastic structure of the material during the filling process. After filling, press supercritical CO 2...

example 3

[0045] Take Haematococcus pluvialis spore powder with astaxanthin content of 1.5%, freeze and pulverize the wall with low temperature liquid nitrogen, the wall breaking rate is 94%, the particle size is 150 mesh, granulate and granulate, and the broken wall of Haematococcus pluvialls The spore powder is wet granulated with physical properties by alcohol, the particle size is 20 mesh, sieved, infiltrated, and the granules made of Haematococcus pluvialis spore powder are soaked in edible alcohol with a mass percentage concentration of 95%. The granule that spore powder is made: edible alcohol=1: 5 is by mass ratio, soaking time is 6 hours, after 1000g glass beads are dried, mix with 4000g Haematococcus pluvialis spore powder granule and carry out gridding filling filling kettle, mix Mesh filling is done manually. Pay attention to the elastic structure of the material during the filling process. After filling, press supercritical CO 2 Fluid extraction operating procedures for f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com