Preparation method of polypyrrole/organically modified attapulgite conductive composite material

A technology for modifying attapulgite and conductive composite materials, which is applied in the field of preparation of conductive composite materials, and can solve the problems of high resistivity, low conductivity, and large amount of attapulgite for nano-conductive composite materials, and achieve conductivity stability Good, improved conductivity, short synthesis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

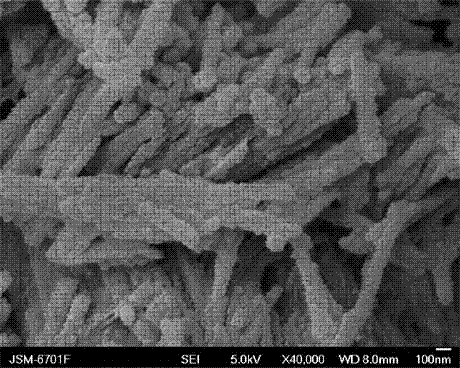

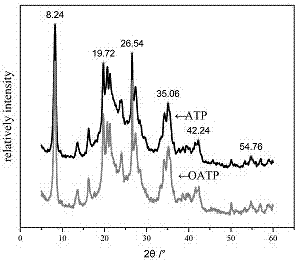

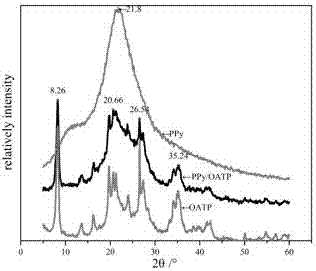

Image

Examples

preparation example Construction

[0016] The present invention is the preparation method of polypyrrole / organic modified attapulgite conductive composite material, and its steps are:

[0017] (1) Mix attapulgite, organic modifier and water, the mass ratio of organic modifier to attapulgite is 0.02-0.05:1, and stir to react;

[0018] (2) Suction filtration to dry the filter cake, and obtain organically modified attapulgite after crushing;

[0019] (3) Mix organically modified attapulgite and water under stirring, the mass ratio of organically modified attapulgite to water is: 0.9~5:100, fully impregnated to make a slurry;

[0020] (4) Add the dopant sulfamic acid, pyrrole monomer, ferric chloride as the oxidant, and the mixture of the above-mentioned attapulgite slurry respectively, and react for 15 minutes at 10-30°C under the protection of nitrogen, and organic modification The mass ratio of attapulgite to pyrrole monomer is: 0.4~2:1, the molar ratio of sulfamic acid to pyrrole monomer is: 0.8:1, and the mol...

Embodiment 1

[0028] First, add 0.08g of cetylpyridine chloride into 100mL of water and stir to dissolve it completely; add 4g of attapulgite to the above solution again, and stir for 4 hours; finally, vacuum-dry the filter cake at 40°C and grind it to obtain Organic modified attapulgite. 0.6191g of the prepared organically modified attapulgite and 50g of water were mixed under stirring, fully impregnated to make a slurry; secondly, 0.0149moL ferric chloride was added to the mixture containing 0.0154moL pyrrole monomer and 0.0084moL sulfamic acid, And in the mixed solution of the above attapulgite slurry, under the protection of nitrogen, react at room temperature for 0.5 hours; again, filter and wash the reaction solution until the filtrate is neutral; finally, vacuum-dry the filter cake at 40°C, and pulverize to obtain black Polypyrrole / organically modified attapulgite conductive powder, the conductivity measured by pressing the tablet is 50.00S•cm-1.

Embodiment 2

[0030] First, add 0.12g of cetylpyridine chloride into 100mL of water and stir to dissolve it completely; add 4g of attapulgite to the above solution again, stir and react for 4h; finally, vacuum-dry the filter cake at 40°C and grind it to obtain Organic modified attapulgite. 0.6191g of the prepared organically modified attapulgite and 50g of water were mixed under stirring, fully impregnated to make a slurry; secondly, 0.0149moL ferric chloride was added to the mixture containing 0.0154moL pyrrole monomer and 0.0084moL sulfamic acid, And in the mixed solution of the above attapulgite slurry, under the protection of nitrogen, react at room temperature for 0.5 hours; again, filter and wash the reaction solution until the filtrate is neutral; finally, vacuum-dry the filter cake at 40°C, and pulverize to obtain black Polypyrrole / organically modified attapulgite conductive powder, the conductivity measured by tableting is 75.18S•cm-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com