Integrated oxidation ditch combining microorganism fruits part

A microbial and oxidation ditch technology, applied in biological water/sewage treatment, chemical instruments and methods, aerobic and anaerobic process treatment, etc., can solve the problems of reducing the effective reaction volume of the oxidation ditch, timely adjustment, and bio-sludge fragmentation. , to increase the contact and purification reaction area, strengthen impact resistance, and increase the effect of biological purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

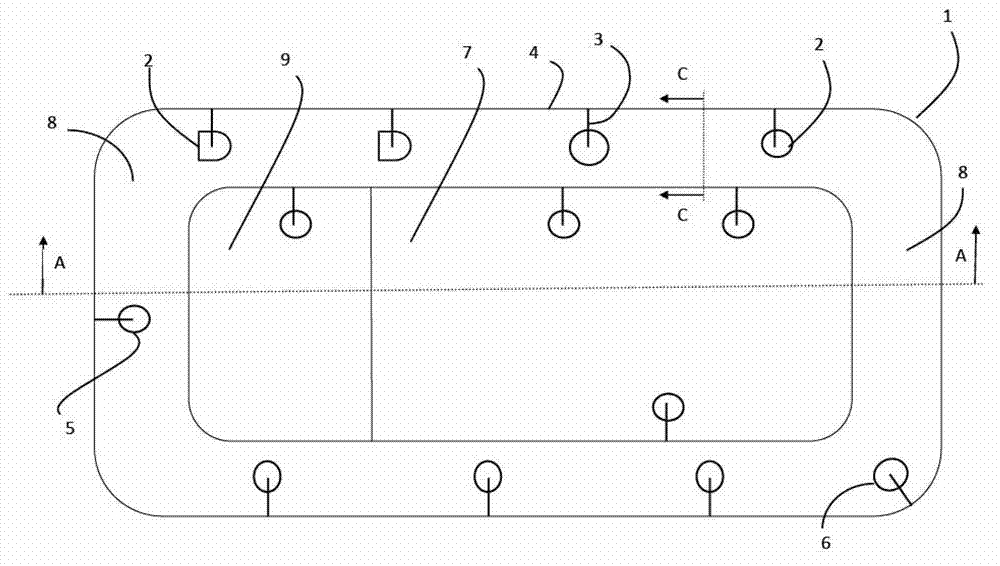

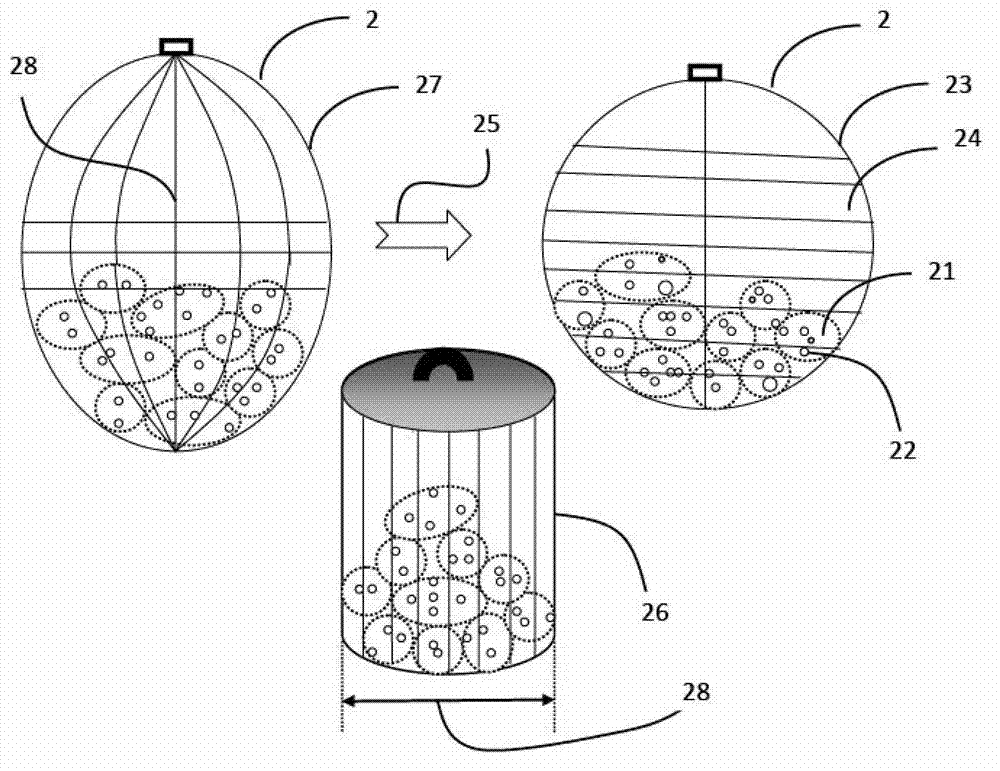

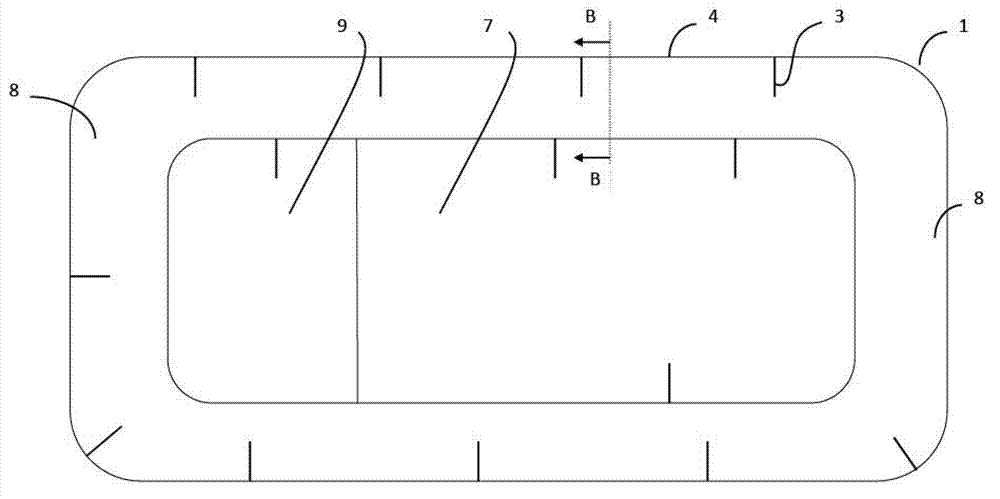

[0071] figure 1 It is a schematic top view of one of the representative implementation examples of the integrated oxidation ditch combined with microbial breeding parts in the present invention, figure 2 It is the side view of various embodiments of the module of the present invention which is composed of microbial breeding parts and suppression mechanism. figure 1 In the present invention, the integrated oxidation ditch combined with microbial infestation parts at least includes a set of integrated oxidation ditch 1, module 2 which is composed of microbial infestation parts and suppression mechanism (module 2 represents the embodiment shown in figure 2 ), and the suppression mechanism connection device 3. The inhibitory mechanism ( figure 2 The container 23 in is an embodiment of the suppression mechanism) to restrain the microorganisms ( figure 2 The movement in 21) makes the position of the microbial breeding part 21 fixed or maintained within a certain range in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com