Chrysene refining method

A refining method and solid technology, which is applied in the refining field of Qu, can solve the problems of restricting the application of Qu, and achieve the effect of mild conditions, simple refining method and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

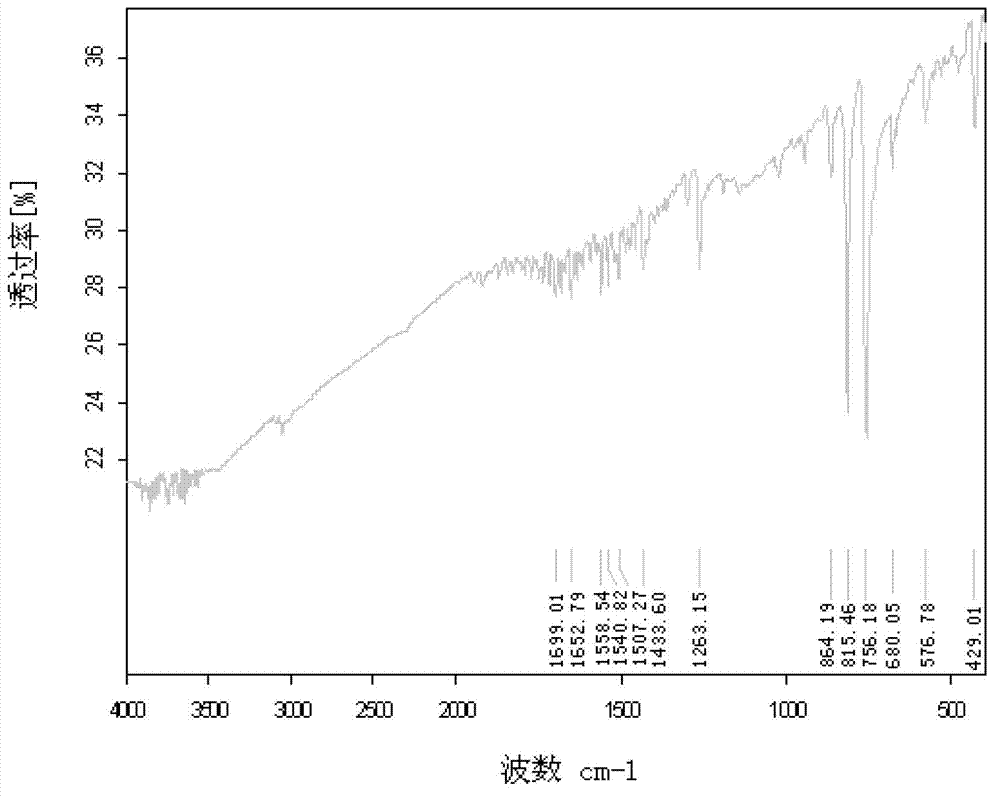

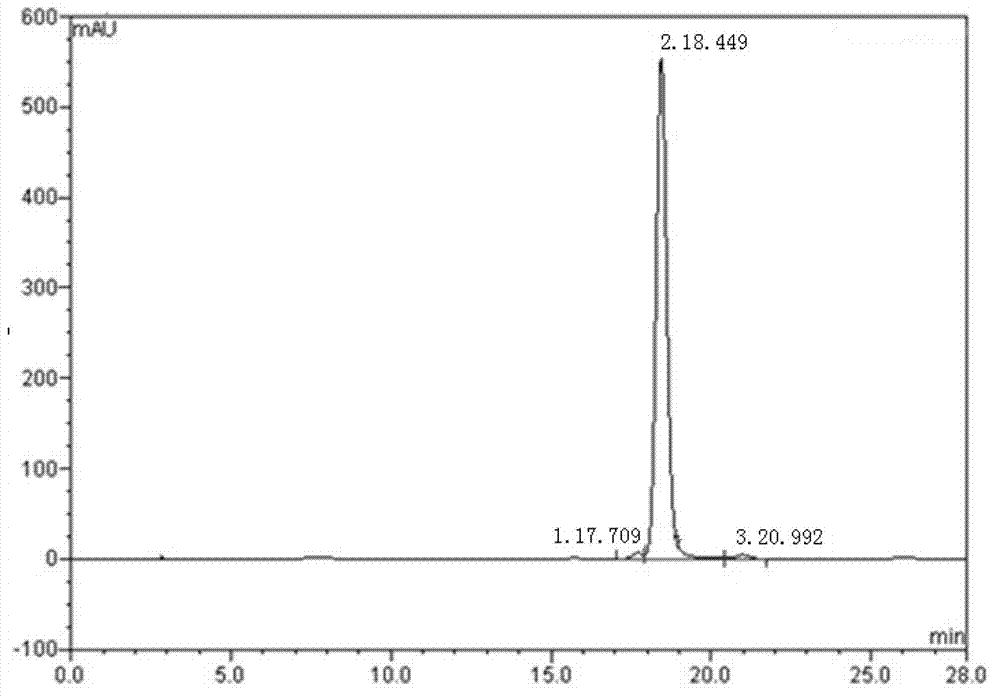

Image

Examples

specific Embodiment approach 1

[0011] Specific embodiment one: the refining method of a kind of bentonite of present embodiment is carried out according to the following steps:

[0012] 1. Mix the raw materials with acid and pickle, filter to obtain a solid after cooling down to room temperature, wash the obtained solid with distilled water, filter and dry; wherein, the acid is one of acetic acid, sulfuric acid, nitric acid, hydrochloric acid and phosphoric acid A mixture of one or more kinds, the pickling condition is a temperature of 20°C to 110°C, pickling for 1 to 10 hours, and the mass ratio of the raw material to the acid is 1: (2 to 30);

[0013] 2. Mix the dried solid with a benzene solvent, heat to the boiling point of the solvent, then cool to room temperature, precipitate the solid, filter and dry, then mix the dried solid with a benzene solvent again, and heat to Solvent boiling point, then cooled to room temperature, precipitated solid, filtered and dried to obtain silver-white flaky crystals, ...

specific Embodiment approach 2

[0016] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the mass volume ratio of solid and distilled water is 1g: (3~10) mL when washing with distilled water in step one. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0017] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the drying conditions in Step 1 and Step 2 are 70-150° C. for 3-20 hours. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

[0018] Verify beneficial effect of the present invention by following test:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com