Method of preparing high-performance glass-fiber reinforced polyamide conductive composite

A conductive composite material and glass fiber technology, applied in the field of nylon composite materials, can solve the problems of limited improvement of material strength modulus, unsatisfactory effect of modified polymers, difficult dispersion of carbon nanotubes, etc., to achieve excellent mechanical properties and The effect of electrical conductivity, simple and easy preparation method, and improvement of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

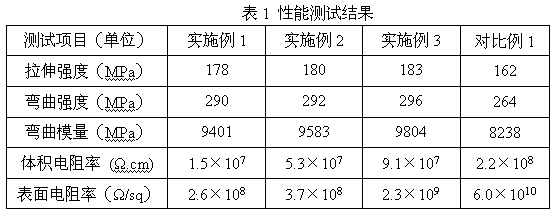

Embodiment 1

[0027] Preparation carbon nanotube concentration is 2g / L, ethylene / maleic anhydride copolymer concentration is the suspension of 1g / L, adds the glass fiber of concentration 200g / L after ultrasonic treatment, utilizes the positive charge on glass fiber surface and carbon nanotube and Electrostatic adsorption between negative charges on the surface of ethylene / maleic anhydride copolymer to obtain multidimensional hybrid reinforced glass fiber reinforcement; mix carbon nanotubes / nylon masterbatch and nylon resin evenly, and then pass through the above glass fiber reinforcement The process of extrusion molding is combined to obtain a high-performance glass fiber reinforced nylon conductive composite material, which contains 30% glass fiber reinforcement and 6.7% carbon nanotube / nylon masterbatch.

[0028] Step (1): In a 5L beaker, add 3g of ethylene / maleic anhydride copolymer and 3L of deionized water, and stir for 12 hours to obtain an aqueous solution of ethylene / maleic anhydride...

Embodiment 2

[0039] Prepare a suspension with a carbon nanotube concentration of 2g / L and an ethylene / maleic anhydride copolymer concentration of 1.5g / L, add glass fibers with a concentration of 200g / L after ultrasonic treatment, and use the positive charge on the surface of the glass fiber to interact with the carbon nanotubes. And the electrostatic adsorption between the negative charges on the surface of ethylene / maleic anhydride copolymer to obtain a multi-dimensional hybrid reinforced glass fiber reinforcement; mix carbon nanotubes / nylon masterbatch and nylon resin evenly, and then mix with the above glass fiber reinforcement Composite through the process of extrusion molding to obtain high-performance glass fiber reinforced nylon conductive composite material. The composite material contains 30% glass fiber reinforcement and 6.7% carbon nanotube / nylon masterbatch.

[0040] Step (1): In a 5L beaker, add 4.5g of ethylene / maleic anhydride copolymer and 3L of deionized water, and stir fo...

Embodiment 3

[0050] Preparation carbon nanotube concentration is 2g / L, ethylene / maleic anhydride copolymer concentration is the suspension of 2g / L, adds the glass fiber of concentration 200g / L after ultrasonic treatment, utilizes the positive charge on glass fiber surface and carbon nanotube and Electrostatic adsorption between negative charges on the surface of ethylene / maleic anhydride copolymer to obtain multidimensional hybrid reinforced glass fiber reinforcement; mix carbon nanotubes / nylon masterbatch and nylon resin evenly, and then pass through the above glass fiber reinforcement The process of extrusion molding is combined to obtain a high-performance glass fiber reinforced nylon conductive composite material, which contains 30% glass fiber reinforcement and 6.7% carbon nanotube / nylon masterbatch.

[0051] Step (1): In a 5L beaker, add 6g of ethylene / maleic anhydride copolymer and 3L of deionized water, and stir for 12 hours to obtain an aqueous solution of ethylene / maleic anhydride...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com