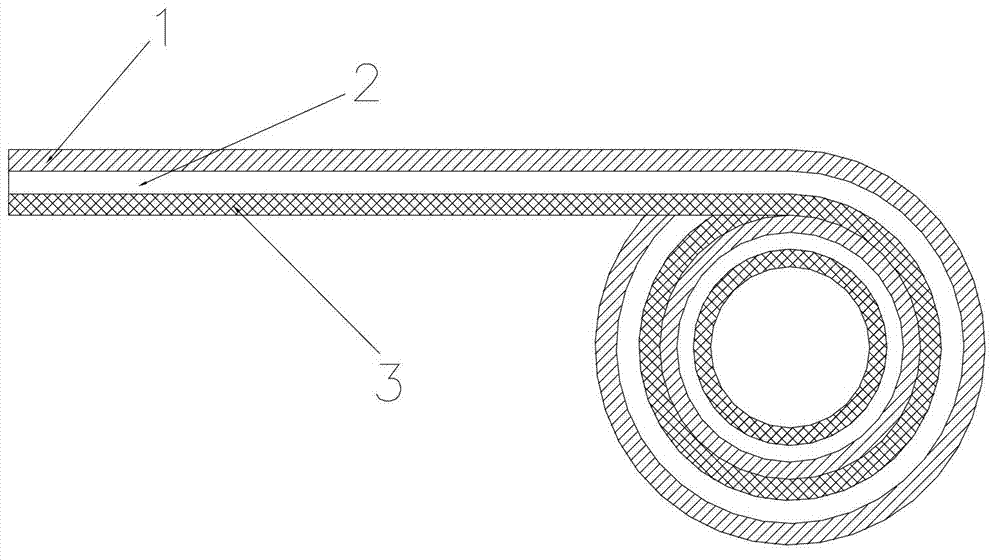

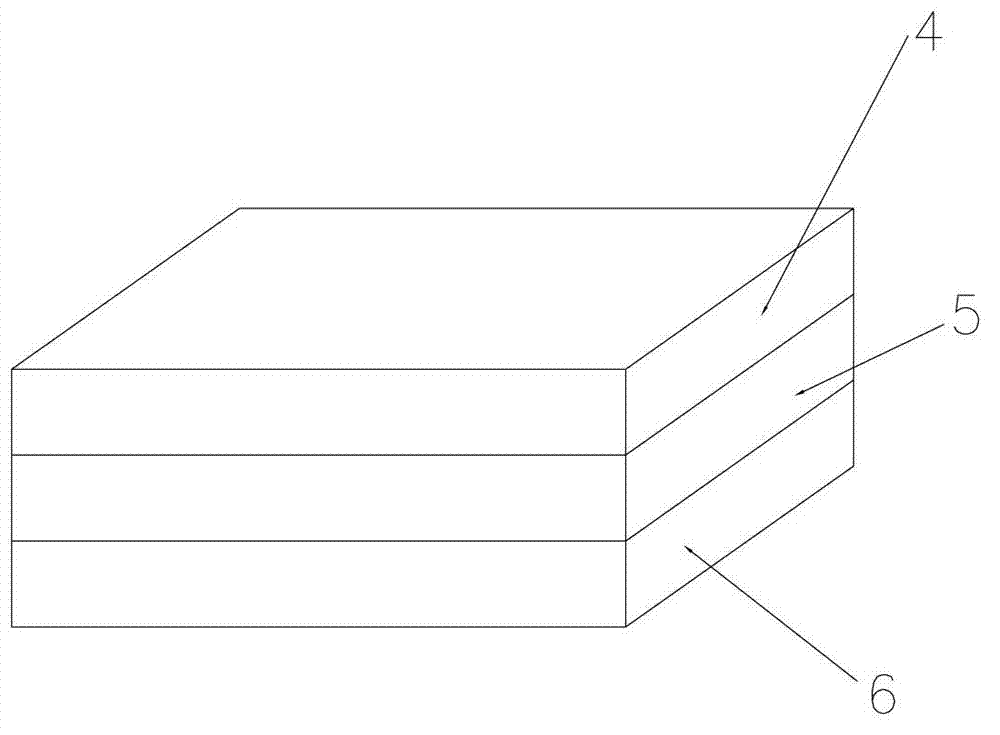

Flexible heat-conducting resin, and prepreg and metal base copper clad laminate prepared from same

A heat-conducting resin and flexible technology, applied in the field of flexible heat-conducting resin, can solve problems such as breakdown discharge, resin cracking, and affecting durable performance, and achieve high insulation performance, less brittle cracking, and improved quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A flexible thermally conductive resin used as an adhesive material for metal-based copper-clad laminates, including 4.849899% by weight of epoxy resin, 0.1% of elastomer components, 0.05% of curing agent, 0.0001% of catalyst, 0.00001 % coupling agent and 95% alumina.

[0026] The elastomer component includes one or more of nitrile rubber, acrylic rubber, styrene polyolefin block elastomer SBS, SEBS, SEP, SEPS, butyl rubber, and acrylate rubber; the elastomer component also Including polyolefin elastomers containing GMA groups, hydroxyl-containing olefins and saturated polyester polyols, silicones, silicone-modified epoxy resins, polyamideimides, silicone-modified polyamideimides , one or more of polyamide, unsaturated polyester, epoxy acrylic resin, active hydroxyl acrylic resin, glycidyl acrylate resin; epoxy resin.

[0027] The curing agent includes one or more of amines, imidazoles, isocyanates, and acid anhydrides; the curing agent can be diaminodiphenyl sulfone (...

Embodiment 2

[0038]The rest are the same as the above-mentioned embodiments, except that a flexible thermally conductive resin is used as an adhesive material for metal-based copper-clad laminates, including 2% by weight of epoxy resin, 50% of elastomer components, 10% curing agent, 5% catalyst, 5% coupling agent and 28% alumina.

Embodiment 3

[0040] The rest are the same as the above-mentioned embodiments, except that a flexible thermally conductive resin is used as an adhesive material for metal-based copper-clad laminates, including 60% by weight of epoxy resin, 28% of elastomer components, 5% curing agent, 3% catalyst, 3% coupling agent and 1% alumina.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com