Up-conversion light emitting material and preparation method thereof

A luminescent material, yttrium oxide technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problem of low luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

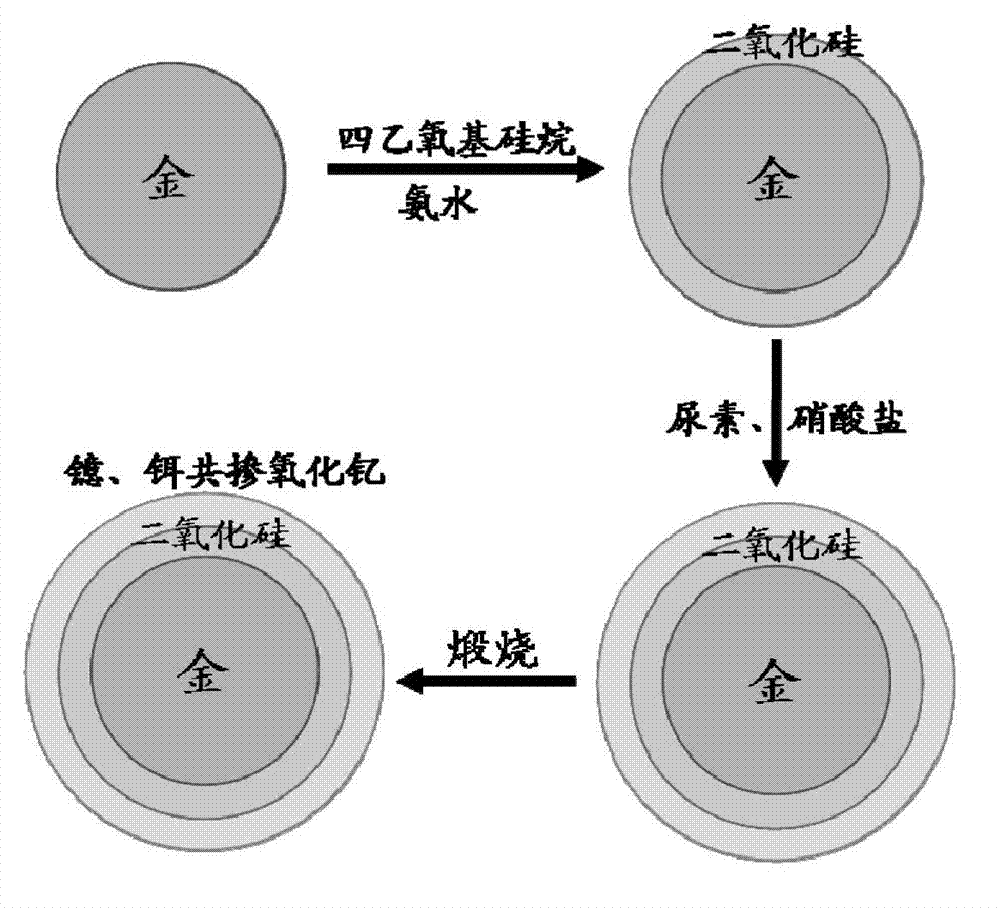

[0038] The present invention also provides a method for preparing an up-conversion luminescent material, which includes the following steps: A) reacting gold nanoparticles, ammonia water and substituted silane in an alcohol solution to obtain Au@SiO 2 Nanoparticles, the substituted silane is selected from one of tetramethoxysilane and tetraethoxysilane, preferably tetraethoxysilane; B) the Au@SiO 2 Nanoparticles, precipitant, yttrium source, ytterbium source and Re source are heated and reacted, dried and then calcined to obtain an up-conversion luminescent material, and the precipitant is selected from one of ammonium bicarbonate and urea.

[0039] According to the present invention, the gold nanoparticles can be commercially available gold nanoparticles or self-made gold nanoparticles, and there is no special limitation, as long as the preparation method is well-known to those skilled in the art. In the present invention, the sodium citrate reduction method is preferably use...

Embodiment 1

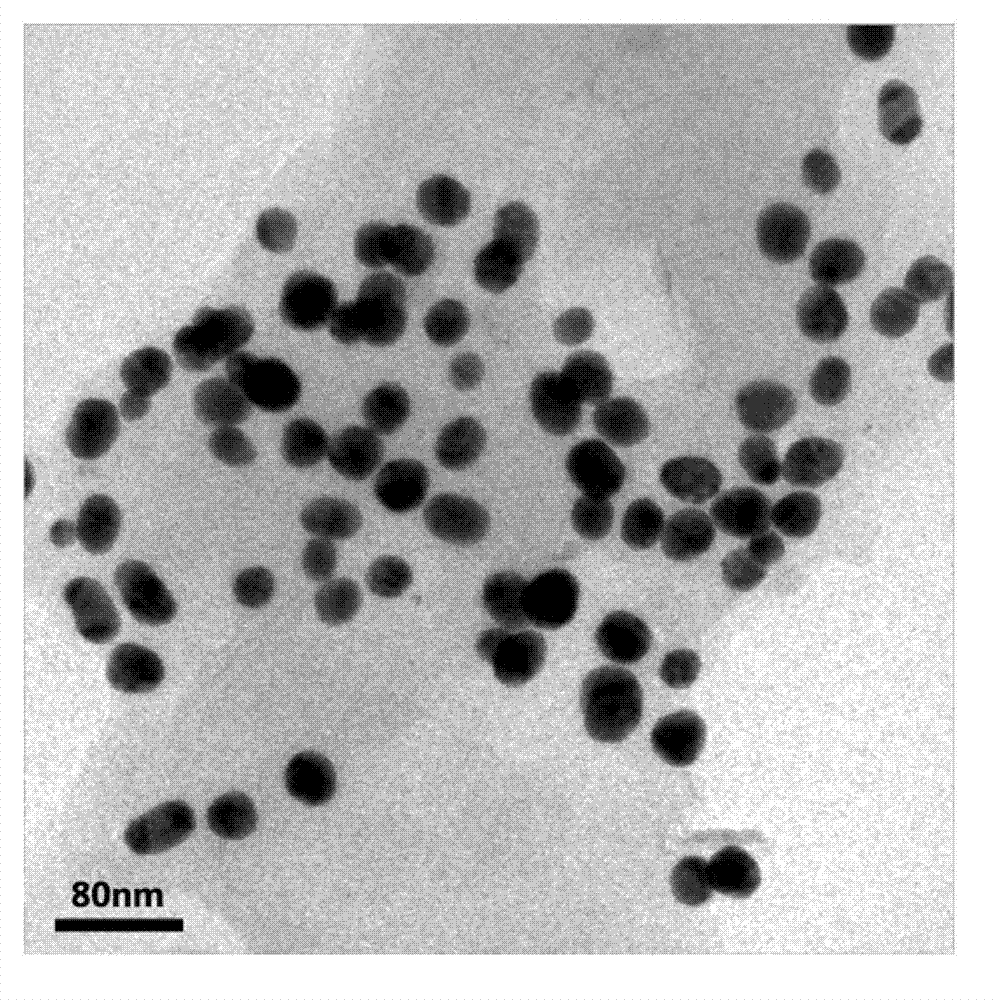

[0050] 1.1 Quickly add 1.3mL of 38.8mM sodium citrate solution to boiling 100mL of 0.3mM chloroauric acid solution, and reflux for 15min to obtain a gold sol solution. The average diameter of gold nanoparticles is 30nm.

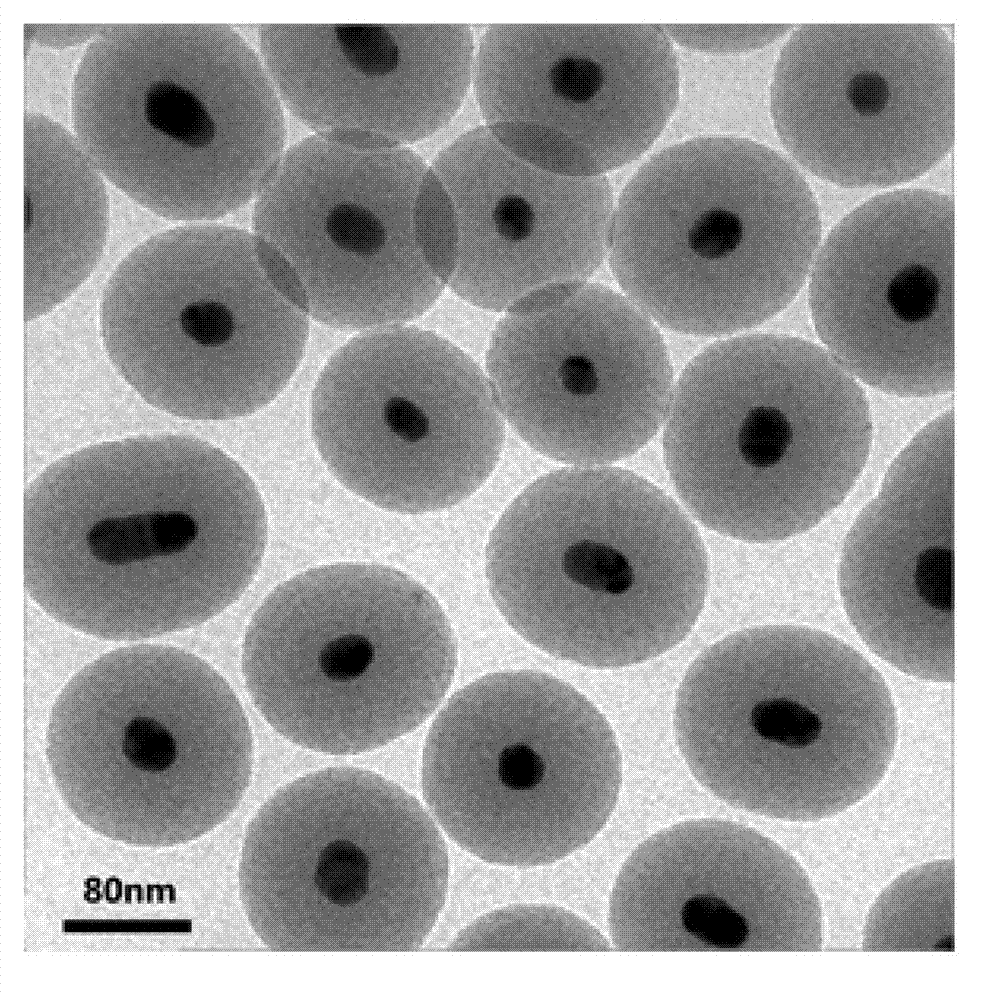

[0051] 1.2 Mix 90 mL of the gold sol solution obtained in 1.1 with 360 mL of isopropanol evenly, add 18 mL of ammonia water and 180 μL of tetraethoxysilane under rapid stirring conditions, react for 8 hours, centrifuge, and wash with ethanol and water three times respectively , to a pH value of 7, and dried for 12 hours to obtain Au@SiO with a silicon dioxide layer of 40nm 2 nanoparticles.

[0052] 1.3 The Au@SiO obtained in 1.2 2 Mix nanoparticles, 100mL deionized water and 2.7g urea evenly, add 0.78mL 0.1mM yttrium nitrate, 0.20mL 0.1mM ytterbium nitrate and 0.02mL 0.1mM erbium nitrate, react at 80°C for 5h, centrifuge, water and Washed with ethanol three times, dried at 80°C for 12h, and then calcined in a muffle furnace at 800°C for 3h to obtain an up-c...

Embodiment 2

[0060] 2.1 Quickly add 1.3mL of 38.8mM sodium citrate solution to boiling 100mL of 0.3mM chloroauric acid solution, and reflux for 15min to obtain a gold sol solution. The average diameter of gold nanoparticles is 30nm.

[0061] 2.2 Mix 90 mL of the gold sol solution obtained in 2.1 with 360 mL of isopropanol evenly, add 18 mL of ammonia water and 45 μL of tetraethoxysilane under rapid stirring conditions, react for 8 hours, centrifuge, and wash with ethanol and water three times respectively , to a pH value of 7, and dried for 12 hours to obtain Au@SiO with a silicon dioxide layer of 25nm 2 nanoparticles.

[0062] 2.3 The Au@SiO obtained in 2.2 2 Mix nanoparticles, 100mL deionized water and 2.7g urea evenly, add 0.78mL 0.1mM yttrium nitrate, 0.20mL 0.1mM ytterbium nitrate and 0.02mL 0.1mM erbium nitrate, react at 80°C for 5h, centrifuge, water and Washed with ethanol three times, dried at 80°C for 12h, and then calcined in a muffle furnace at 800°C for 3h to obtain an up-co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com