Method and device for growing silicon carbide single crystal by multi-crucible physical vapor transport technology

A physical vapor transport, silicon carbide single crystal technology, applied in the growth of polycrystalline materials, chemical instruments and methods, single crystal growth and other directions, can solve the problems of insignificant advantages, increased energy consumption, etc. The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

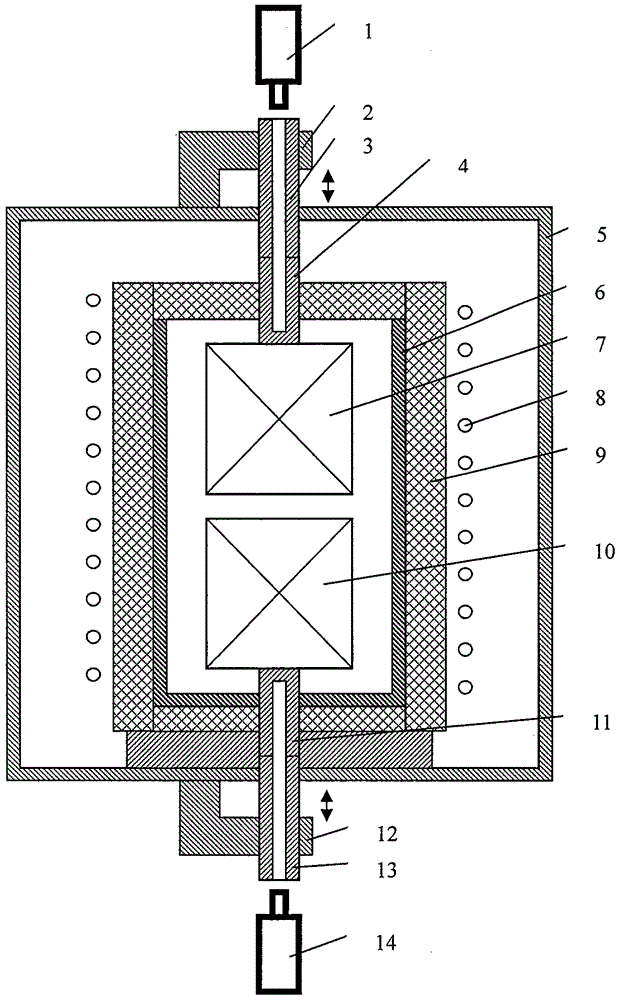

[0026] figure 1 Shown is a schematic diagram of the device structure for growing silicon carbide single crystals by double-crucible physical vapor transport technology. In this device, the graphite heating element 6 is wrapped in the insulating material 9, the induction coil 8 is located outside the insulating material 9, and the two graphite crucibles 7 and 10 arranged up and down are located in the furnace formed by the graphite heating element 6 and the insulating material 9. , the upper crucible 7 is suspended on the lifting rod 3 through the upper temperature measuring tube 4, and the lower crucible 10 is placed upside down on the lowering rod 13 through the lower temperature measuring tube 11. The temperature of the upper and lower crucibles is determined by the main temperature control device and the secondary temperature control device. The temperature control device includes infrared thermometer 1 or 14, Eurotherm temperature control meter and intermediate frequency p...

Embodiment 2

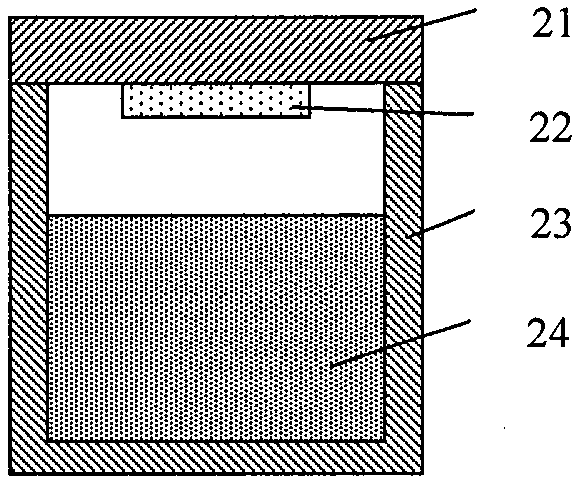

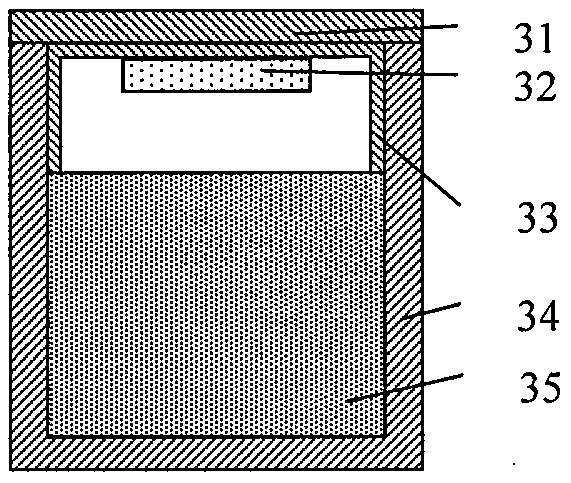

[0028] Taking the growth of silicon carbide single crystal by double-crucible physical vapor transport technology as an example, this embodiment adopts figure 1 The device structure shown, figure 2The upper crucible structure shown and the lower crucible structure shown in Fig. 3(a). In the upper crucible, high-purity silicon carbide powder is used as the raw material for growth, and in the lower crucible, high-purity silicon carbide powder is used as the raw material, and the polycrystalline silicon carbide block obtained by sintering in argon at 1800°C for 5 hours is used as the growth raw material. The process is as follows: respectively place a certain amount of high-purity silicon carbide powder and silicon carbide polycrystalline block in the upper and lower graphite crucibles, tighten the upper crucible cover with the silicon carbide seed crystal attached, so that the gap between the raw material and the seed crystal in the upper crucible The distance between them is ...

Embodiment 3

[0030] Embodiment 3 adopts figure 1 The device structure shown and figure 2 For the structure of the upper crucible shown and the structure of the lower crucible shown in Figure 3(b), the temperature measured by the upper crucible is used as the main control temperature. Compared with Example 2, the temperature control method and process parameters remain the same, but the selected lower crucible structure is different. Embodiment 2 adopts the lower crucible structure shown in FIG. 3( a ), and this embodiment adopts the lower crucible structure shown in FIG. 3( b ). From the size of the silicon carbide crystal obtained by above method and device (as Figure 5(a) and 5(b) ), the silicon carbide crystal grown in the upper crucible has a diameter of 60 mm and a thickness of 21-23 mm. The silicon carbide crystal grown in the lower crucible has a diameter of 65 mm and a thickness of 12-13 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com