Burning system of heavy oil boiler and method thereof

A combustion system and combustion method technology, applied in the direction of combustion method, combustion type, combustion equipment, etc., to achieve the effect of reducing nitrogen oxides and broadening the market prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the drawings.

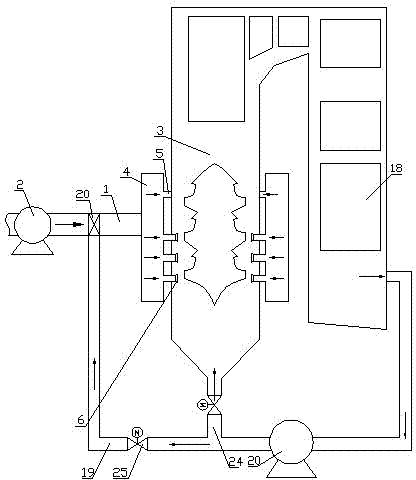

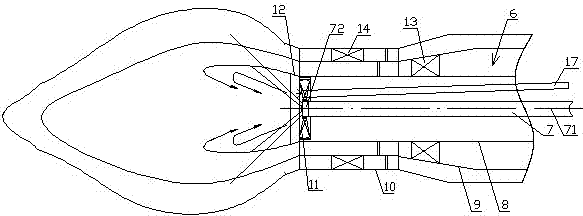

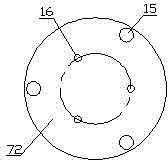

[0023] Such as Figure 1 to Figure 5 As shown, the combustion system of the heavy oil boiler includes an air inlet pipe 1, an air blower 2, two wind boxes 4 arranged opposite to each other on the outside of the furnace 3, an exhaust air nozzle 5 provided on each wind box 4, Several burners 6 and igniters 17 below the air nozzle 5, the burn-out air nozzles 5 and several burners 6 on the two wind boxes 4 are arranged in opposition, and each burner 6 includes atomized oil arranged from the inside to the outside The gun 7, the primary air pipe 8, the secondary air pipe 9 and the tertiary air pipe 10 are connected by connecting rods between adjacent air pipes. The atomizing oil gun 7 includes a connected oil pipe 71 and a nozzle 72. The primary air pipe 8 The inner front end is provided with a burner 11, the front end of the primary air pipe 8 is provided with an outwardly bent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com