Metal dielectric film wideband pulse compressed grating

A metal medium, broadband pulse technology, applied in diffraction grating and other directions, to achieve the effect of high diffraction efficiency and high damage threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

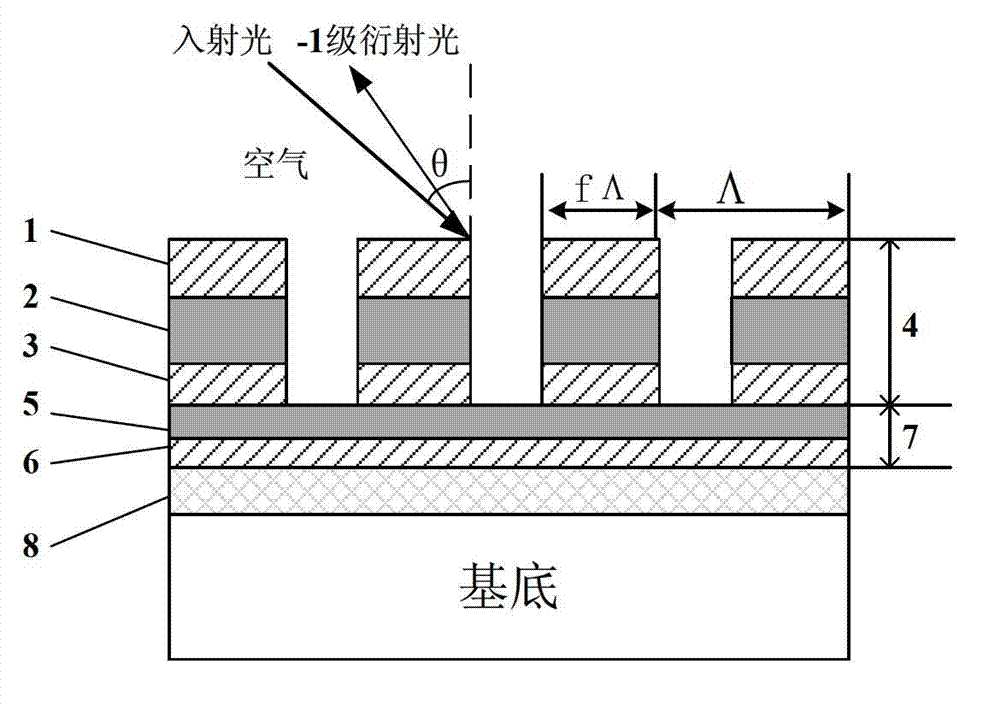

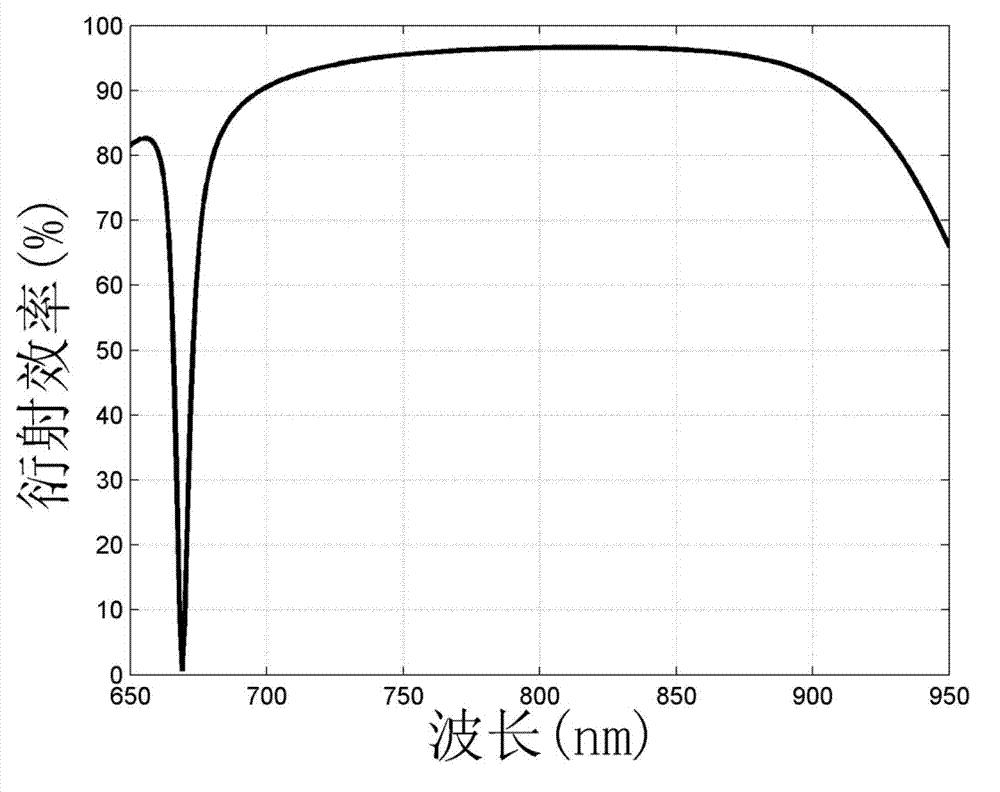

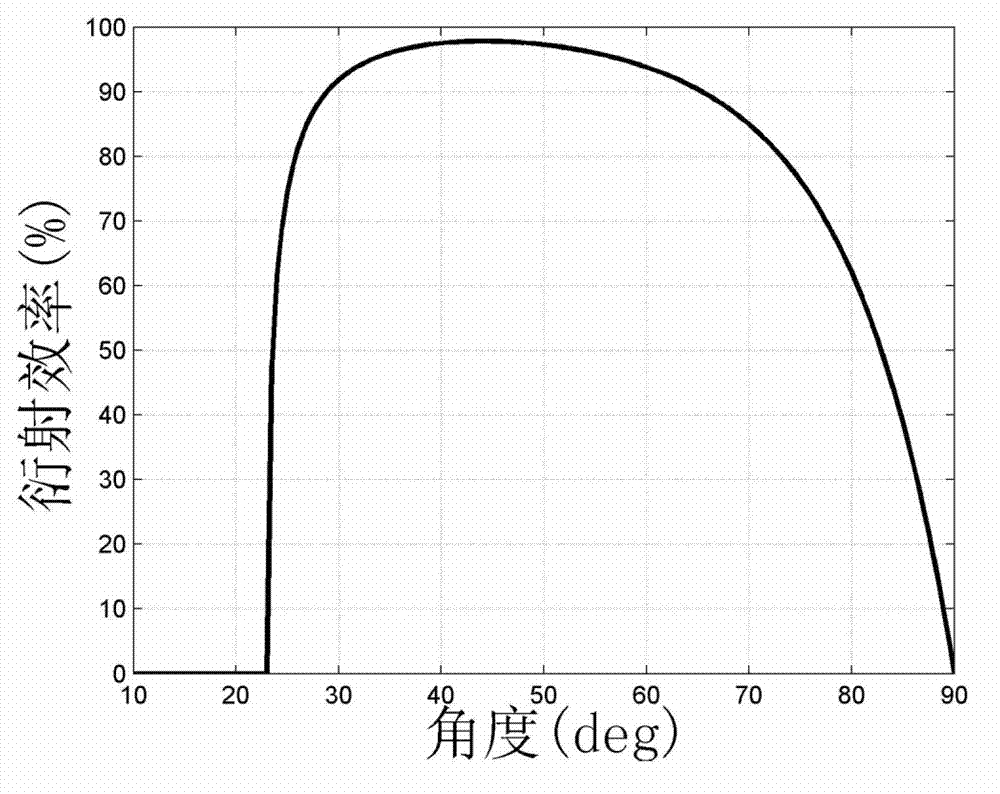

[0027] The metal dielectric film pulse compression grating is composed of a quartz substrate, a metal layer 8, a matching layer 7 composed of two dielectric films and a rectangular etching layer 4. The period of the rectangular etching layer 4 is 574.7 nanometers, the duty ratio is 0.26, and the SiO of the third low refractive index film layer 1 2 (refractive index 1.45) thickness 100 nanometers, the material of the second high refractive index film layer 2 is HfO 2 (refractive index 1.96) layer thickness 149 nm, second low refractive index film layer 3 SiO 2 The thickness is 57nm. The first high refractive index layer 5 of the matching layer 7 is HfO 2 , with a thickness of 119 nanometers; the first low refractive index layer 6 is SiO2, with a thickness of 81 nanometers. The gold layer 8 has a thickness of 200 nm. Such as figure 2 When the incident angle is 53°, for the incident light of 800 nm, the -1 order diffraction efficiency of the grating TE is the highest, great...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com