Negative photoresist developing solution and application thereof

A technology of negative photoresist and developing solution, applied in the field of developing solution, can solve the problems of conductive short circuit, unfavorable influence of transistor control switch, difficult to be cleaned, etc., to achieve better permeability, elimination of unfavorable influence, and increase of developing rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

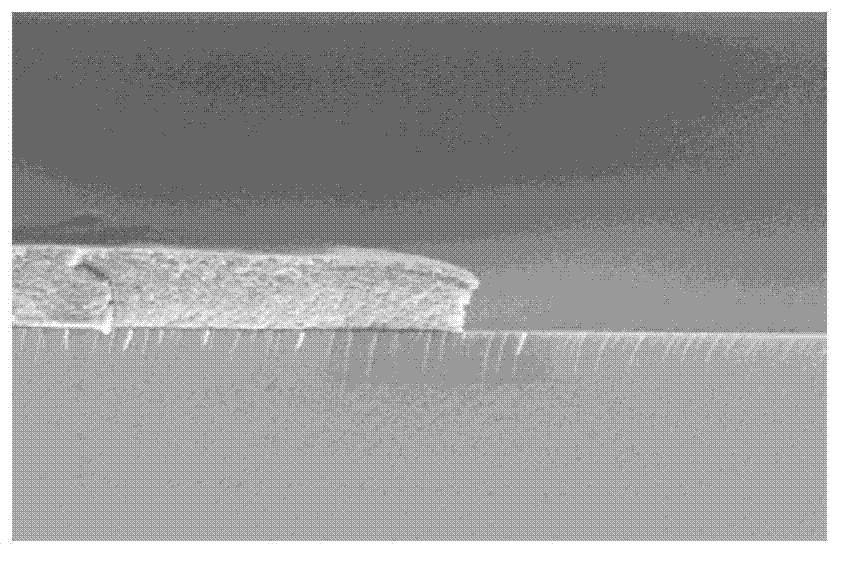

[0030] Take 240g of TMAH aqueous solution with a mass concentration of 25%, take 250g of a TEAH aqueous solution with a mass concentration of 20%, add them to a 1L volumetric flask, and then add 1L of high-purity water to obtain an aqueous solution with a concentration of 6%TMAH+5%TEAH. When in use, dilute it into a 100L developer temperature-controlled tank, fill the tank with high-purity water whose temperature is controlled at 23°C±1°C, stir evenly, and prepare an aqueous solution with a concentration of 0.06%TMAH+0.05%TEAH. In addition, G glue with a film thickness of 2.0 μm has been prepared and exposed, and the exposure pattern is a rectangle with a width of about 800 μm. Transfer the G glue glass substrate to the developing tank, and develop it by spraying. The developing time is 20s, and the liquid temperature is always controlled at 23°C±1°C. After developing, water washing, blow drying and post-baking are carried out to obtain a developed photoresist substrate. Subs...

Embodiment 2

[0032]Take 400g of TMAH aqueous solution with a mass concentration of 25%, and at the same time take 50g of alcohol ether ammonium phosphate, add it to a 1L volumetric flask, and then add 1L of high-purity water to obtain an aqueous solution with a concentration of 10%TMAH+5% alcohol ether ammonium phosphate. When in use, dilute it into a 100L developer temperature-controlled tank, fill the tank with high-purity water whose temperature is controlled at 23°C±1°C, stir evenly, and prepare an aqueous solution with a concentration of 0.10% TMAH+0.05% alcohol ether ammonium phosphate. In addition, R glue with a film thickness of 2.0 μm has been prepared and exposed, and the exposure pattern is a rectangle with a width of about 800 μm. Transfer the R glue glass substrate to the developing tank, and develop it by spraying. The developing time is 25s, and the liquid temperature is always controlled at 23°C±1°C. After developing, water washing, blow drying and post-baking are carried o...

Embodiment 3

[0034] Take 240g of TMAH aqueous solution with a mass concentration of 25%, and another 200g of TMAC aqueous solution with a mass concentration of 20%, and at the same time take 50g of phenol ether sulfate ester salt, add it to a 1L volumetric flask, and then add 1L of high-purity water to obtain 6%TMAH+4 %TMAC+5% aqueous solution of phenol ether sulfate salt concentration. When in use, dilute it into a 100L developer temperature-controlled tank, fill the tank with high-purity water whose temperature is controlled at 23°C±1°C, stir evenly and configure it to a concentration of 0.06%TMAH+0.04%TMAC+0.05%phenol ether sulfate aqueous solution. In addition, G glue with a film thickness of 2.0 μm has been prepared and exposed, and the exposure pattern is a rectangle with a width of about 800 μm. Transfer the G glue glass substrate to the developing tank, and develop it by spraying. The developing time is 25s, and the liquid temperature is always controlled at 23°C±1°C. After devel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com