Preparation method of ferroferric oxide nano sheet

A technology of ferric oxide and nanosheets, which is applied in the direction of iron oxide/hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of low saturation magnetization, complex process, long growth cycle, etc., and achieve reliable production process, Reproducible and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

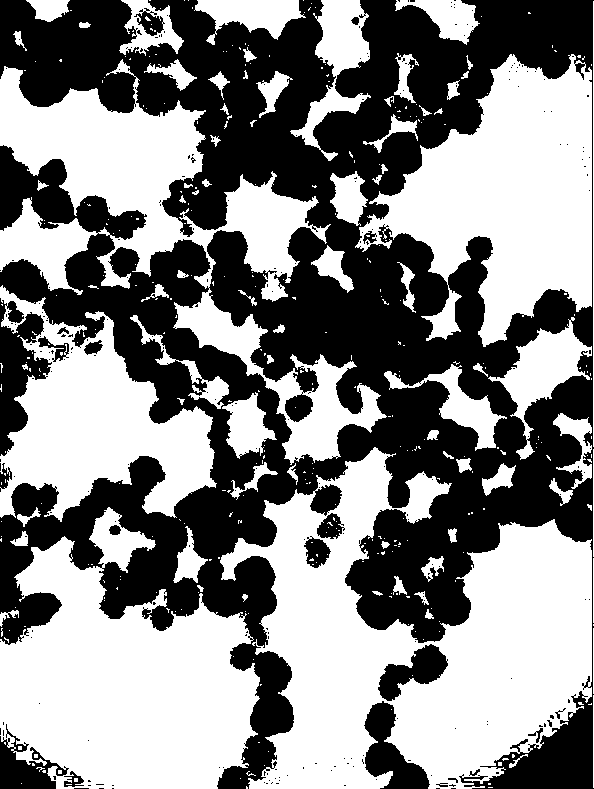

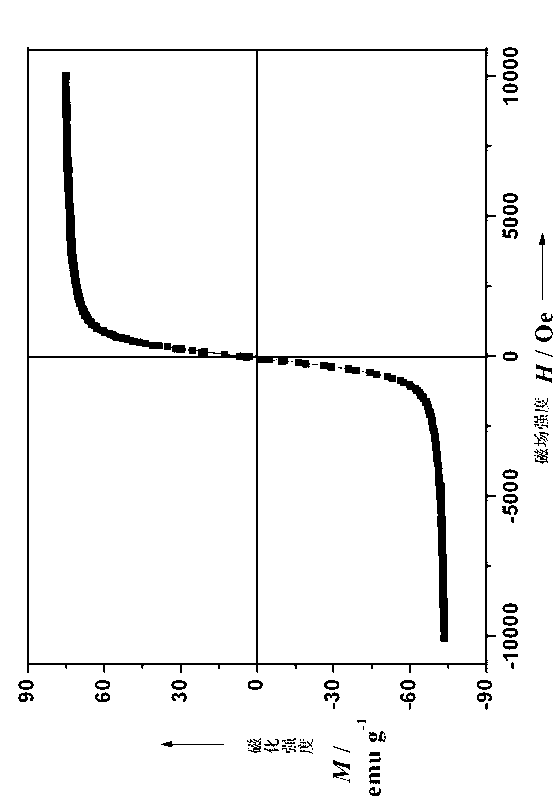

Image

Examples

Embodiment 1

[0017] Embodiment 1, a kind of preparation method of iron ferric oxide nanosheet, its steps are as follows:

[0018] (1) Add an appropriate amount of ethylene glycol into the reaction kettle and perform magnetic stirring; then FeCl with a weight ratio of 3.50:1:4.8 3 ·6H 2 O, FeCl 2 4H 2 O and surfactant are added in ethylene glycol, make it mix homogeneously; Described surfactant is selected from arbitrary in citric acid, polyvinylpyrrolidone PVP, polyethylenediamine PEI, sodium dodecylsulfonate SDS A sort of;

[0019] (2) Slowly add strong alkali into the mixed solution; after stirring the mixed solution for 2 hours, take out the stirring bar, then put the reaction kettle into the iron shell, close it and place it in a constant temperature oven at 180°C, and react for 12 hours; The strong base is selected from one of LiOH, NaOH or KOH; the strong base and FeCl 2 4H 2 The weight ratio of O is 20:1;

[0020] (3) After the reaction kettle is naturally cooled to room temp...

Embodiment 2

[0021] Embodiment 2, a kind of preparation method of iron ferric oxide nanosheet, its steps are as follows:

[0022] (1) Add an appropriate amount of ethylene glycol into the reaction kettle and carry out magnetic stirring; then FeCl with a weight ratio of 4.0:1:5.2 3 ·6H 2 O, FeCl 2 4H 2 O and surfactant are added in ethylene glycol, make it mix homogeneously; Described surfactant is selected from arbitrary in citric acid, polyvinylpyrrolidone PVP, polyethylenediamine PEI, sodium dodecylsulfonate SDS A mixture of 2 or 3 or all 4 kinds, the ratio is selected according to the needs;

[0023] (2) Slowly add strong alkali into the mixed solution; after the mixed solution is stirred for 12 hours, take out the stirring bar, then put the reaction kettle into the iron shell, close it and place it in a constant temperature oven at 200°C, and react for 48 hours; The strong base is a mixture of two or three of LiOH, NaOH or KOH, and the ratio is selected according to the needs; the ...

Embodiment 3

[0025] Embodiment 3, a kind of preparation method of ferric oxide nanosheet, its steps are as follows:

[0026] (1) Add an appropriate amount of ethylene glycol into the reaction kettle, and carry out magnetic stirring; then FeCl with a weight ratio of 3.71:1:5 3 ·6H 2 O, FeCl 2 4H 2 O and surfactant are added in ethylene glycol, make it mix homogeneously; Described surfactant is selected from arbitrary in citric acid, polyvinylpyrrolidone PVP, polyethylenediamine PEI, sodium dodecylsulfonate SDS A sort of;

[0027] (2) Slowly add strong alkali into the mixed solution; after stirring the mixed solution for 8 hours, take out the stirring bar, then put the reaction kettle into the iron shell, close it and place it in a constant temperature oven at 190°C, and react for 24 hours; The strong base is selected from one of LiOH, NaOH or KOH; the strong base and FeCl 2 4H 2 The weight ratio of O is 70:1;

[0028] (3) After the reaction kettle is naturally cooled to room temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com