Method for preparing selenylation poly mannuronic acid and application of selenylation poly mannuronic acid

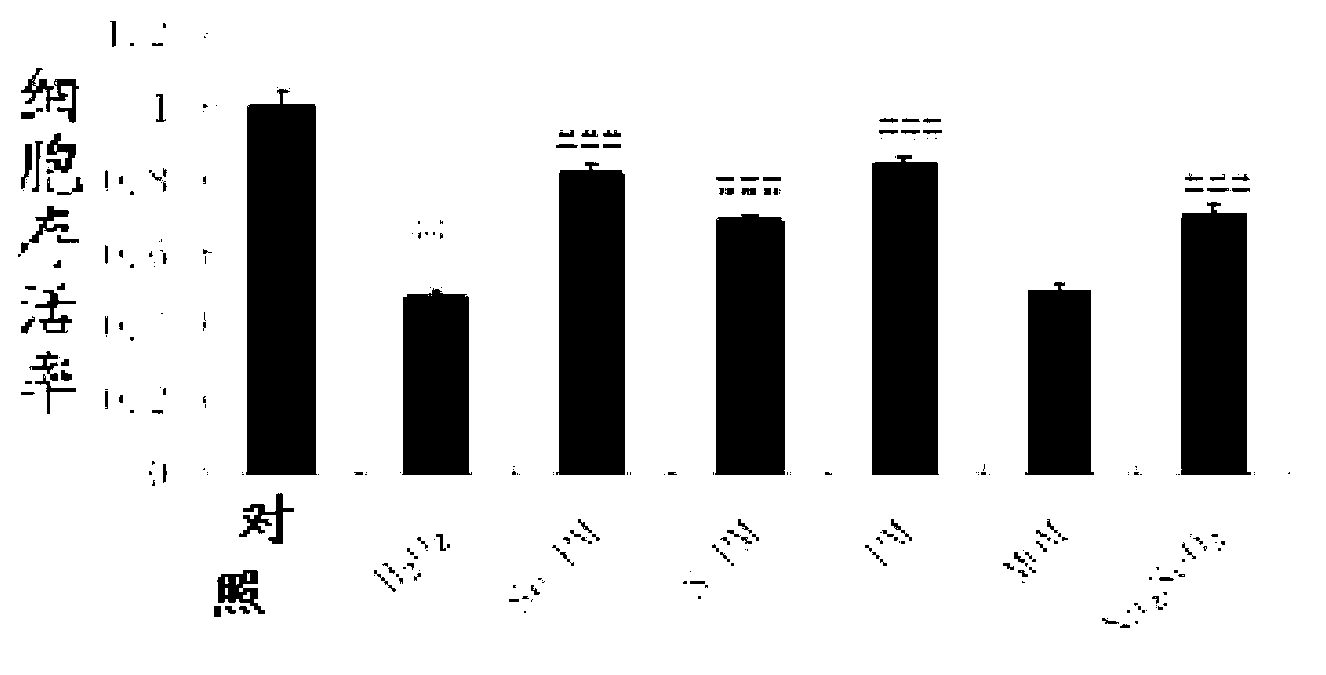

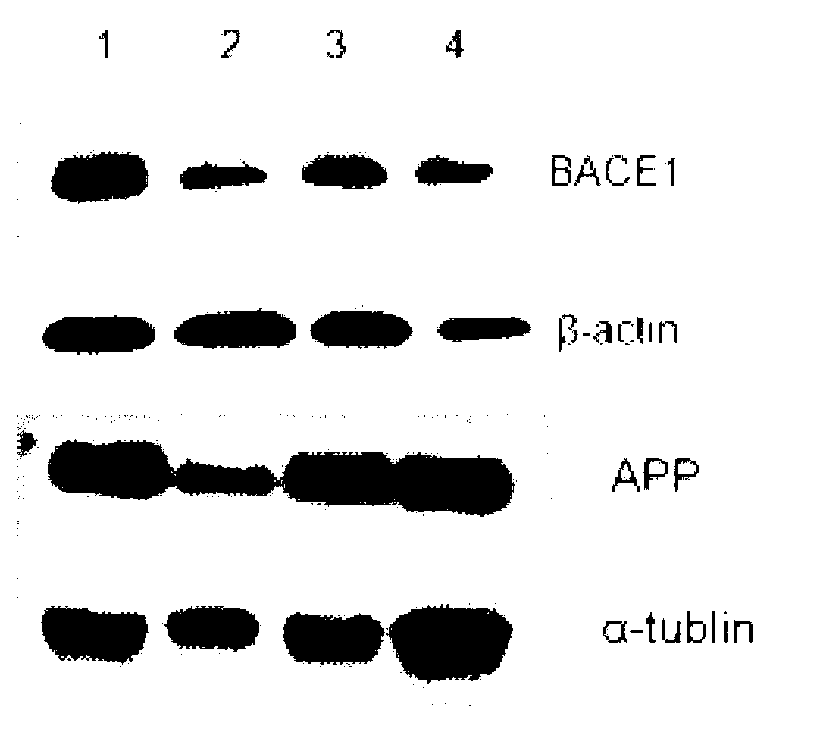

A technology of polymannuronic acid and mannuronic acid, which is applied in the field of preparation of selenized polymannuronic acid, can solve the problems that have not been reported on the effect of selenium polysaccharides on AD, and achieve the prevention and treatment of Alzheimer's disease , high yield and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The embodiment of the present invention provides a kind of preparation method of selenized polymannuronic acid, it comprises the following steps:

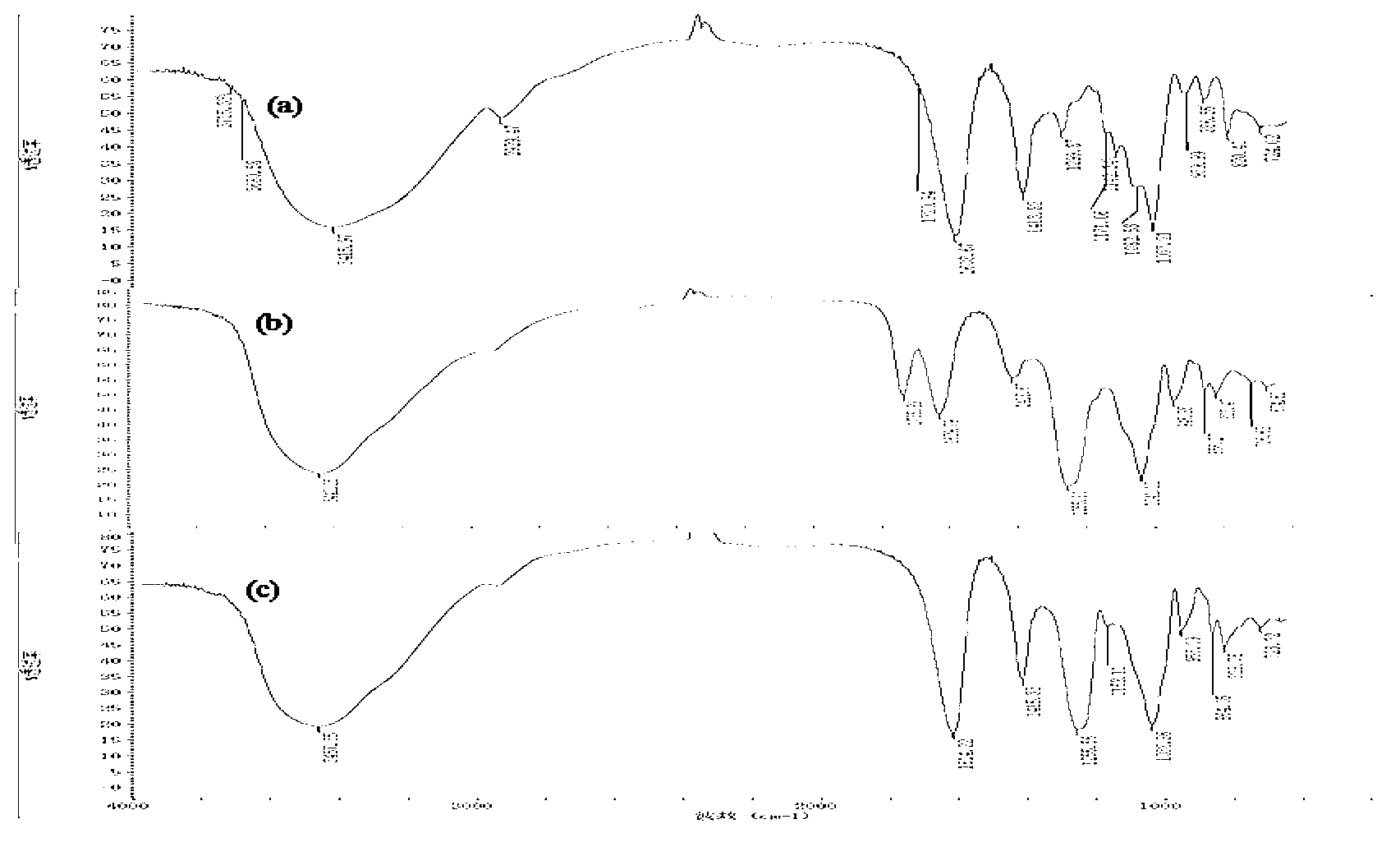

[0018] S01: Preparation of sulfonated polymannuronic acid: suspend polymannuronic acid (PM) in anhydrous organic solvent, add sulfur trioxide-pyridine complex dissolved in anhydrous organic solvent under stirring condition, React at a constant temperature of 100°C for 1 to 10 hours, add 2 to 4 times the volume of 95% ethanol, centrifuge the reaction product, then wash with 95% ethanol, add water to dissolve, adjust the pH to neutral with alkali, dialyze, and filter , freeze-dried to obtain sulfonated polymannuronic acid (S-PM);

[0019] S02: Preparation of selenized polymannuronic acid: the sulfonated polymannuronic acid and selenite are mixed in acidic solution, Ba 2+ Under the catalysis of 20 ~ 100 ℃ constant temperature for 2 ~ 20 hours, the molar ratio of sulfonated polymannuronic acid to barium chloride is 1:1 ~ 100, a...

Embodiment 1

[0029] Suspend 100 mg of dried polymannuronic acid (PM) in DFM, add 600 mg of sulfur trioxide-pyridine complex dissolved in 5 mL of anhydrous DMF under stirring conditions, react at a constant temperature of 60 ° C for 4 hours, add 3 Double the volume of 95% ethanol, centrifuge the reaction product, wash with 95% ethanol, add water to dissolve, adjust the pH to neutral with alkali, dialyze, filter, and freeze-dry to obtain sulfonated polymannuronic acid, wherein the sulfur content is 12.5%, DS=1.29, and the average yield is 78%;

[0030] Preparation of selenized mannuronic acid: the 100mg sulfonated polymannuronic acid and 200mg selenite were added to 50mL0.5% HNO 3 In solution, 25mg BaCl 2 Under the catalysis of 60 ℃ reaction 8h, adding sulfate to remove Ba 2+ , centrifuge to take the supernatant, adjust the pH to neutral with alkali, and then dialyze with a dialysis bag with a molecular weight cut-off of 1000, until the ascorbic acid detection dialysis bag liquid does not ...

Embodiment 2

[0032] Suspend 100 mg of dried polymannuronic acid (PM) in DFM, add 600 mg of sulfur trioxide-pyridine complex dissolved in 5 mL of anhydrous DMF under stirring conditions, react at a constant temperature of 20 ° C for 10 hours, add 2 Double the volume of 95% ethanol, centrifuge the reaction product, wash with 95% ethanol, add water to dissolve, adjust the pH to neutral with alkali, dialyze, filter, and freeze-dry to obtain sulfonated polymannuronic acid;

[0033] Preparation of selenized mannuronic acid: add the 100mg sulfonated polymannuronic acid and 10mg selenite to 50mL0.5% HNO 3 In solution, 25mg Ba(NO 3 ) 2 Under the catalysis of 20 ℃ reaction 20h, adding sulfate to remove Ba 2+ , centrifuge to take the supernatant, adjust the pH to neutral with alkali, and then dialyze with a dialysis bag with a molecular weight cut-off of 1000 until the ascorbic acid detection dialysis bag liquid does not turn red. Filtrate and freeze-dry to obtain the selenized polymannuronic acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com