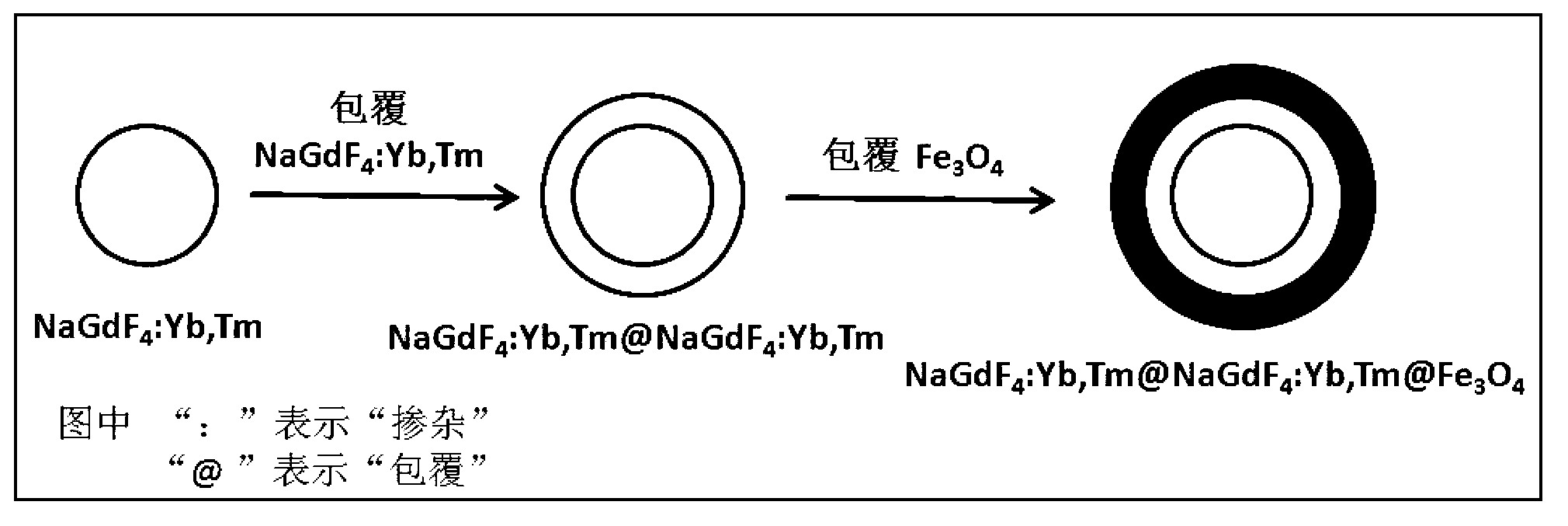

Core-shell-structure photomagnetic double-function nano composite material and preparation method thereof

A technology of nanocomposite material and core-shell structure is applied in the field of preparation of core-shell structure multifunctional nanocomposite materials, and achieves the effects of wide design practicability, high product purity, and overcoming low fluorescence/magnetic intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

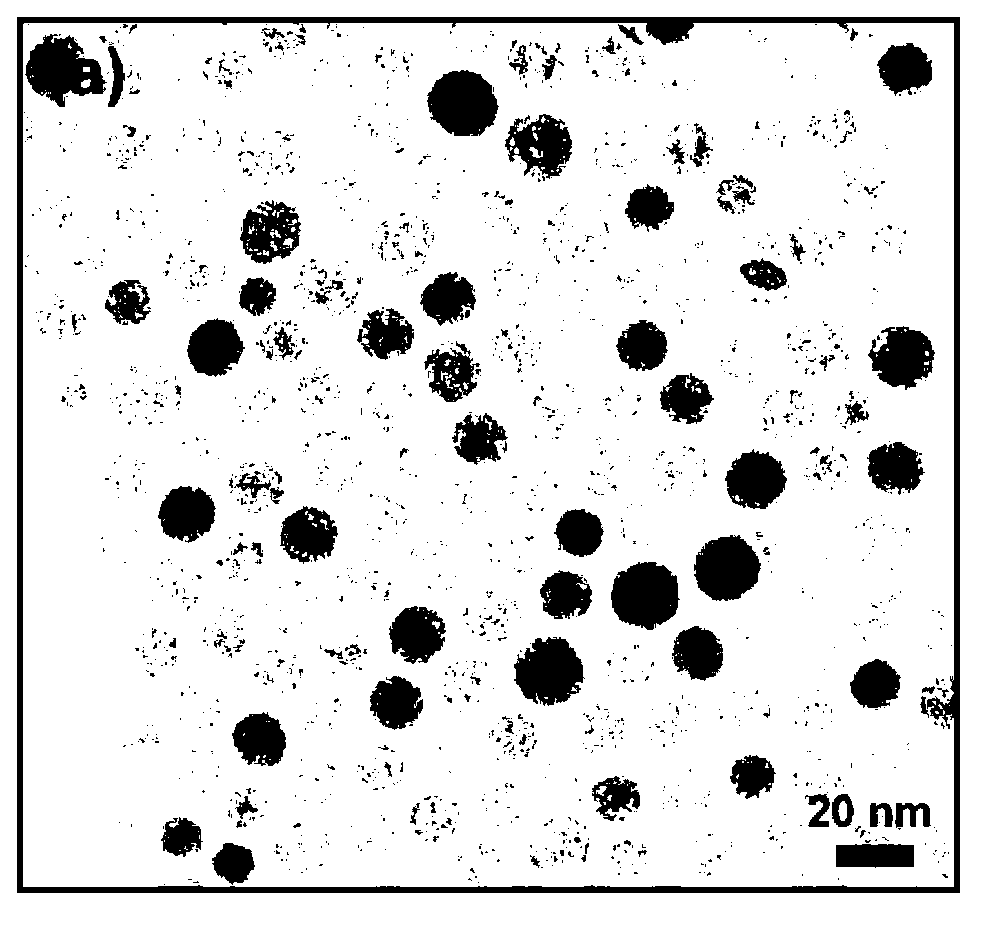

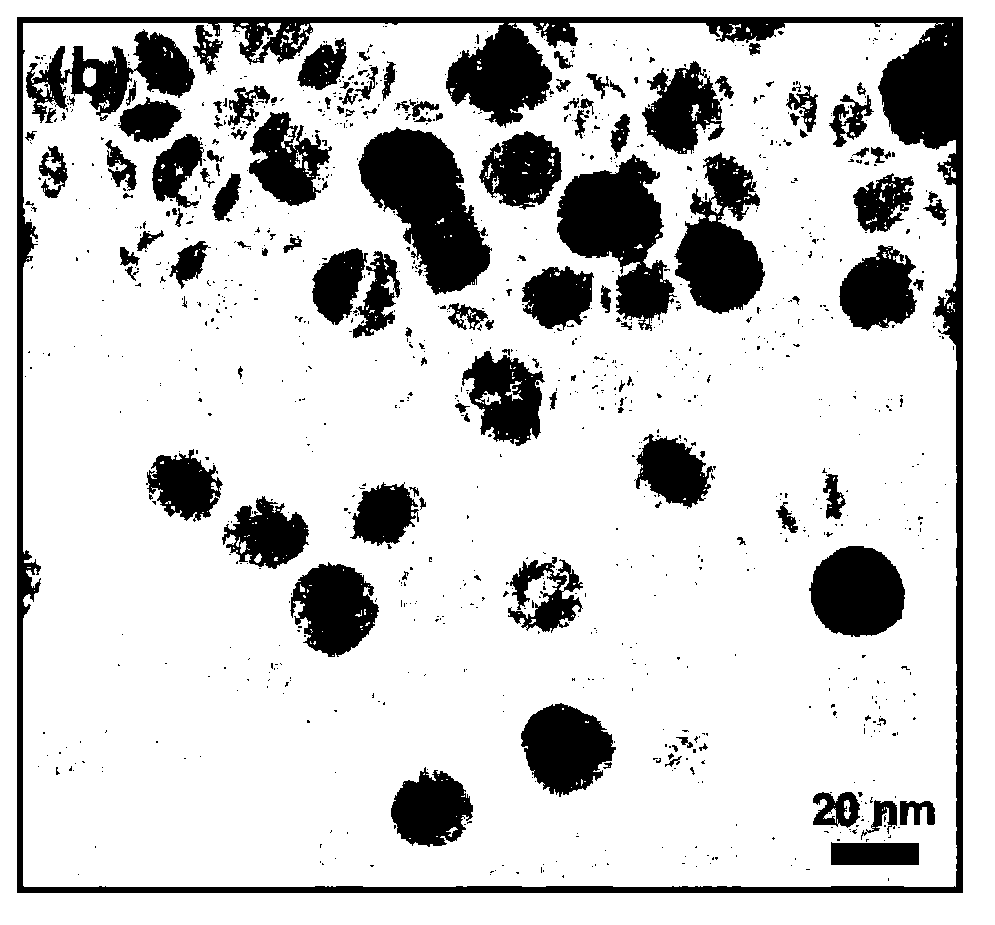

Image

Examples

specific Embodiment approach ( 1

[0023] (1) Preparation of up-conversion fluorescent NaGdF by high-temperature pyrolysis 4 : Yb, Tm nanocrystalline core material. First, weigh a total amount of 1mmol rare earth oleate Gd(C 18 h 33 o 2 ) 3 , Yb(C 18 h 33 o 2 ) 3 and Tm(C 18 h 33 o 2 ) 3 , placed in a three-neck flask. Another 0.21 g NaF, 15 mL oleic acid and 15 mL octadecene were added. Heat up to 100°C and pass N 2 Air for 30 minutes. in N 2 Under air protection, the system was warmed up to 280°C, and kept warm for 2.5h. After the reaction was finished, it was naturally cooled until the temperature was reduced to 70° C., and ethanol was added to precipitate the product. Wash twice more with ethanol and cyclohexane. The product is stored in 5mL cyclohexane to obtain Yb and Tm co-doped NaGdF 4 (expressed as NaGdF 4 :Yb, Tm) nanocrystalline core material.

[0024] (2) Preparation of core-shell structure NaGdF by high temperature pyrolysis 4 :Yb,TmNaGdF 4 : Yb, Tm nanomaterials. The specif...

specific Embodiment approach ( 2

[0028] (1) Preparation of up-conversion fluorescent NaGdF by high-temperature pyrolysis 4 : Yb, Tm nanocrystalline core material. First, weigh a total amount of 0.8mmol rare earth oleate Gd(C 18 h 33 o 2 ) 3 , Yb(C 18 h 33 o 2 ) 3 and Tm(C 18 h 33 o 2 ) 3 , placed in a three-neck flask. Another 0.16 g NaF, 12 mL oleic acid and 12 mL octadecene were added. Heat up to 100°C and pass N 2 Air for 30 minutes. in N 2 Under air protection, the system was warmed up to 280° C. and kept for 1 h. After the reaction was finished, it was naturally cooled until the temperature was reduced to 70° C., and ethanol was added to precipitate the product. Wash twice more with ethanol and cyclohexane. The product is stored in 5mL cyclohexane to obtain NaGdF 4 : Yb, Tm nanocrystalline core material.

[0029] (2) Preparation of core-shell structure NaGdF by high temperature pyrolysis 4 :Yb,TmNaGdF 4 : Yb, Tm nanomaterials. The specific experimental steps are as follows: 0.16g N...

specific Embodiment approach ( 3

[0031] (1) Preparation of up-conversion fluorescent NaGdF by high-temperature pyrolysis 4 : Yb, Tm nanocrystalline core material. First, weigh a total amount of 1.2mmol rare earth oleate Gd(C) with a stoichiometric ratio of 80:17:3 18 h 33 o 2 ) 3 , Yb(C 18 h 33 o 2 ) 3 and Tm(C 18 h 33 o 2 ) 3 , placed in a three-neck flask. Another 0.25 g NaF, 18 mL oleic acid and 18 mL octadecene were added. Heat up to 100°C and pass N 2 Air for 30 minutes. in N 2 Under air protection, the system was warmed up to 280°C, and kept warm for 5h. After the reaction was finished, it was naturally cooled until the temperature was reduced to 70° C., and ethanol was added to precipitate the product. Wash twice more with ethanol and cyclohexane. The product is stored in 5mL cyclohexane to obtain NaGdF 4 : Yb, Tm nanocrystalline core material.

[0032] (2) Preparation of core-shell structure NaGdF by high temperature pyrolysis 4 :Yb,TmNaGdF 4 : Yb, Tm nanomaterials. The specific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com