Method for preparing load metal fullerene nano-micron material by supercritical fluid technology

A supercritical fluid and metal-loaded technology, which is applied in the production of fullerenes, nano-carbons, and bulk chemicals, can solve the problems of high surface tension, low repetition rate, and low metal loading, and achieve high loading and repeatability. The effect of high rate and many kinds of metals

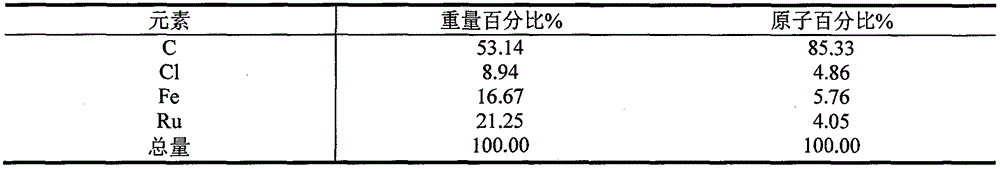

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Weigh 20mgC 60 The powder is in a 20ml glass bottle with a purity of 99.9%. As a commercially available product, take 20ml of toluene with a graduated cylinder and add it to the glass bottle, sonicate for 10 minutes, and filter.

[0029] 2. Put the C in step 1 60 - The toluene solution was divided into four groups, 5ml of each group was placed in a 20ml glass bottle; 15ml of isopropanol was injected into each group, and then cultured in an airtight incubator at 8°C in a low-temperature incubator.

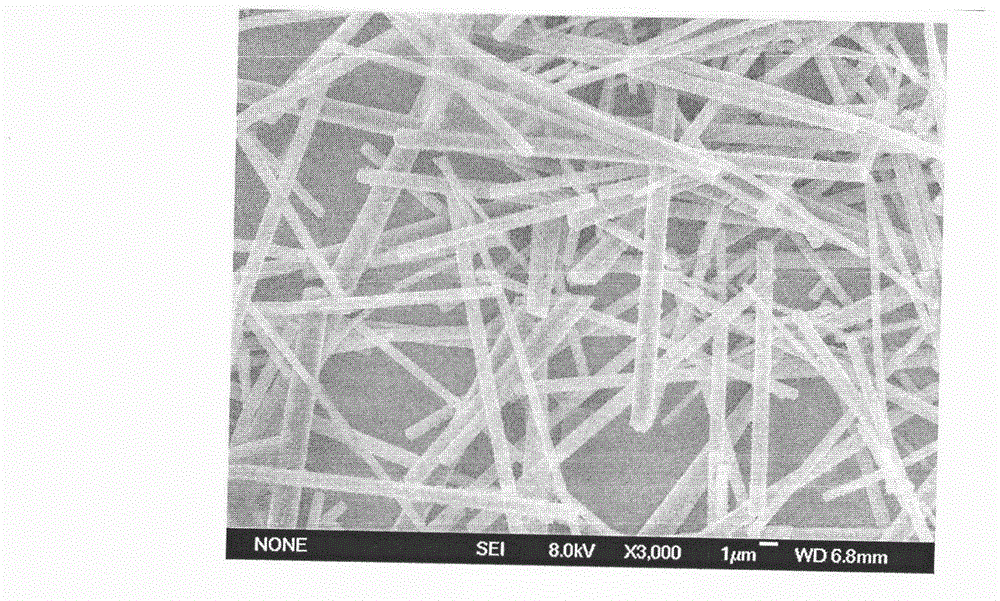

[0030] 3. After standing still for 12 hours, fullerene nanofibers with a length of about 20-50 μm can be prepared, and the scanning electron microscopy (SEM) photos are shown in figure 1 . Use a sieve with a pore size of about 20 μm to filter out the sample, wash it, dry it and weigh it, about 10 mg.

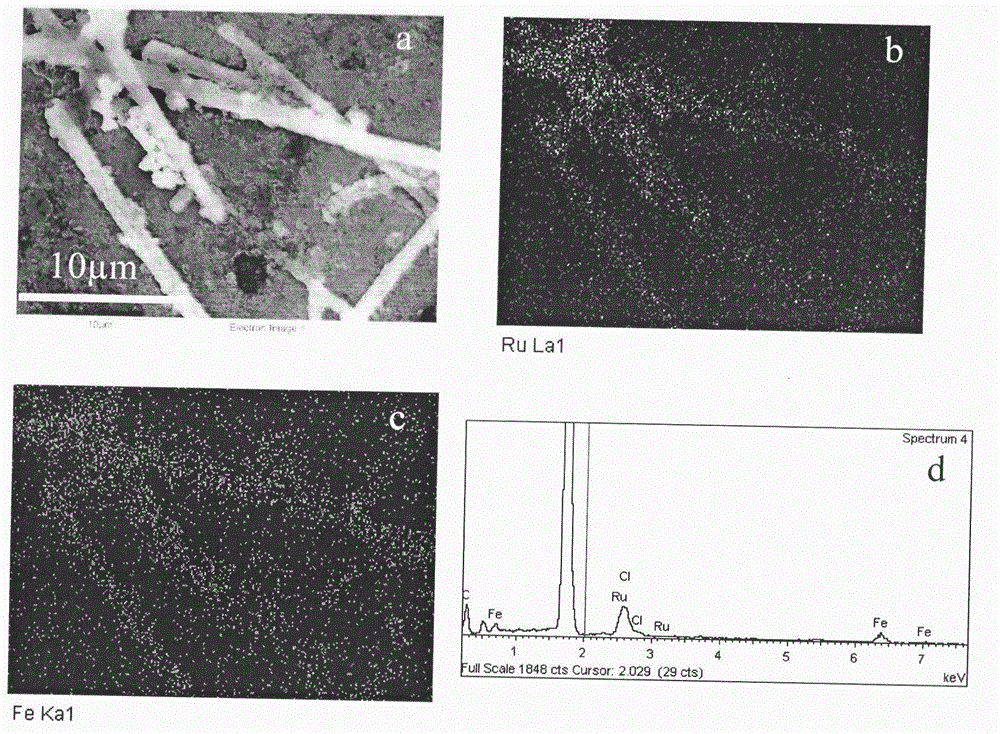

[0031] 4. Weigh 10 mg of ruthenium chloride, dissolve it in 20 ml of distilled water to form a ruthenium chloride solution, disperse the fullerene nano-micron fibers prep...

Embodiment 2

[0038] Example 2 has the same steps as Example 1, and the liquid-liquid interface method is used to prepare fullerene nano-micron materials, but the difference is that pyridine is used as a good solvent.

Embodiment 3

[0040] Example 3 has the same steps as Example 1, and the liquid-liquid interface method is used to prepare fullerene nano-micron materials, but the difference is that pyrrolidone is used as a good solvent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com