A kind of method for preparing aluminide silicon borate molecular sieve in situ

A technology for preparing silicon aluminide and molecular sieve, which is applied in the direction of crystalline aluminosilicate zeolite, etc., which can solve the problems of crystal structure damage, loss of active sites, and increased cost, etc., to achieve a large range of silicon-aluminum ratio, improve efficiency, and save time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

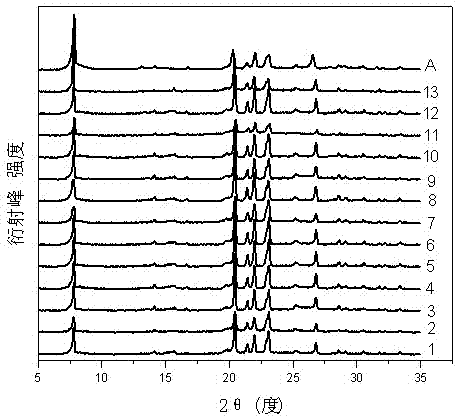

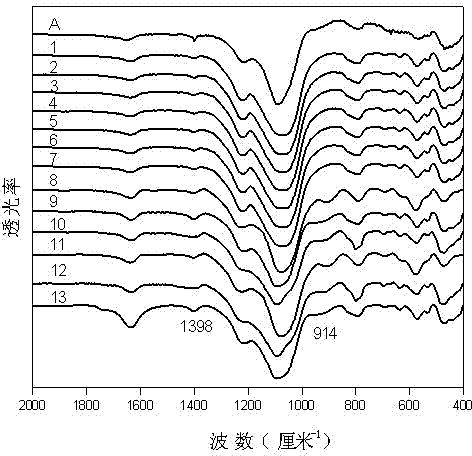

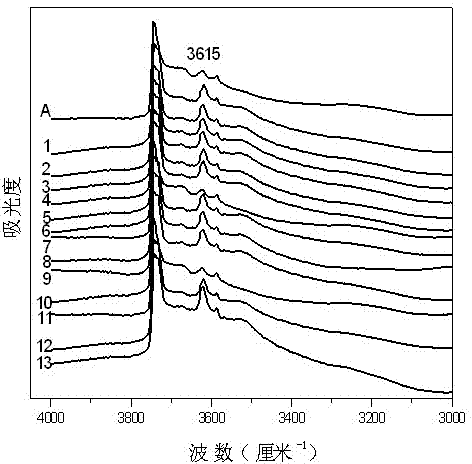

Image

Examples

Embodiment 1

[0033] 1. Prepare Al-SSZ-33 molecular sieve seed crystals according to the traditional method (refer to US 5120425)

[0034] 0.14 g sodium tetraborate, 34.80 g hydroxide N,N,N-trimethyl-8-ammonium-tricyclo[5.2.1.0 2.6 ] Decane (concentration 5.69wt%) and 3.75 g sodium hydroxide solution (concentration 9.61wt%) were added to 9.20 g water and stirred evenly to obtain reaction mixture I; 3.60 g white carbon black was added to reaction mixture I and stirred evenly to obtain Reaction mixture II; the reaction mixture II was placed in a closed reactor, and crystallized in a homogeneous reactor with a rotational speed of 30 rpm. Crystallized at 160°C for 6 days to obtain B-SSZ-33 molecular sieve. B-SSZ-33 molecular sieves were calcined at 600 °C for 4 h to remove the template, and 1 mol L -1 In the aluminum nitrate solution (solid: liquid = 1:50), react at 90 °C for 3 days to obtain the Al-SSZ-33 molecular sieve sample, which is recorded as A (as the seed crystal required later).

[...

Embodiment 2

[0038] 0.22 g aluminum hydroxide, 2.00 g iodide N,N,N-trimethyl-8-ammonium-tricyclo[5.2.1.0 2.6 ] Decane, 3.20 g of sodium hydroxide solution (concentration 9.61wt%) were added to 45.00 g of water, and stirred evenly to obtain reaction mixture I; 33 molecular sieve sample A) and 1.50 g tetraethylammonium hydroxide solution (concentration 27.43wt%) were added to the reaction mixture I, stirred evenly to obtain the reaction mixture II; The crystallization was carried out in a homogeneous reactor at rpm. The crystallization is divided into two stages, the heating rate is raised to 150 °C at a rate of 1.5 °C / min, and the crystallization is carried out at 150 °C for 60 hours, and then the temperature is increased to 190 °C at a rate of 4.0 °C / min, and continued at 190 °C After crystallization for 48 hours, Al-SSZ-33 was obtained.

Embodiment 3

[0040] 0.22 g aluminum hydroxide, 1.80 g iodide N,N,N-trimethyl-8-ammonium-tricyclo[5.2.1.0 2.6 ] decane, 8.50 g N,N,N-trimethyl-8-ammonio-tricyclohydroxide [5.2.1.0 2.6 ] Decane (concentration 5.69wt%), 3.20 g sodium hydroxide solution (concentration 9.61wt%) were added in 37.00g water, stirred evenly to obtain reaction mixture I; 3.72 g white carbon black, 0.50 g seed crystal (using example 1 Self-made Al-SSZ-33 molecular sieve sample A) and 0.40 g concentrated ammonia water (concentration 28wt%) were added to the reaction mixture I, and stirred evenly to obtain the reaction mixture II; The crystallization was carried out in a homogeneous reactor at rpm. The crystallization is divided into two stages, the heating rate is raised to 160 °C at a rate of 2.0 °C / min, and the crystallization is carried out at 160 °C for 40 hours, and then the temperature is rapidly raised from 160 °C to 190 °C at 4.5 °C / min, and at 190 °C The crystallization was continued for 48 hours to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com