Method for decomplexing heavy metal ammonia complex in high-concentration ammonia-nitrogen wastewater

A technology for ammonia nitrogen wastewater and ammonia complexes, applied in the direction of water pollutants, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve the problem of difficult removal of heavy metals, achieve no secondary pollution, low treatment cost, The effect of good processing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

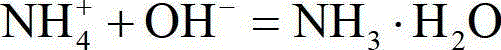

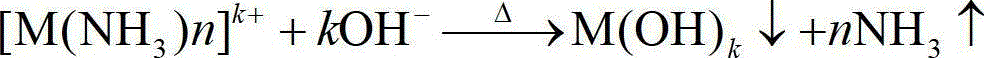

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] For copper-containing ammonia nitrogen wastewater, where the concentration of copper ions is 127mg / L and the concentration of ammonia nitrogen is 1722mg / L, the specific process is as follows:

[0032] 1) Add potassium hydroxide solution to the above wastewater to adjust the pH of the wastewater to 11, so that the ammonium ions in the wastewater are converted into ammonia molecules, and there are excess hydroxide ions;

[0033] 2) Put the alkaline wastewater described in step 1) into the stripping tower for treatment; control the temperature of the stripping tower by controlling the steam flow rate and steam pressure input into the stripping tower, so that the temperature of the tower kettle is 185 °C, and the temperature at the upper 10m of the tower kettle is The temperature is 175°C;

[0034] 3) Adjust the flow rate of the waste water through the spacing of the multi-stage trays in the stripping tower, so that it takes 12 seconds to pass through the 10m area described...

Embodiment 2

[0037] For the ammonia nitrogen wastewater containing molybdenum, the molybdenum ion concentration is 2129mg / L, the ammonia nitrogen concentration is 46003mg / L, the specific process is as follows:

[0038] 1) Add sodium hydroxide solution to the above wastewater to adjust the pH of the wastewater to 13.5, so that the ammonium ions in the wastewater are converted into ammonia molecules, and there are excess hydroxide ions;

[0039] 2) Put the alkaline wastewater described in step 1) into the stripping tower for treatment; control the temperature of the stripping tower by controlling the steam flow rate and steam pressure input into the stripping tower, so that the temperature of the tower bottom is 102°C, and the temperature at the top of the bottom 10m The temperature is 95°C;

[0040] 3) Adjust the flow rate of the waste water through the spacing of the multi-stage trays in the stripping tower, so that it takes 30 seconds to pass through the 10m area described in step 2); the...

Embodiment 3

[0043]For ammonia nitrogen wastewater containing nickel and cobalt, the concentration of nickel ions is 217mg / L, the concentration of cobalt ions is 60mg / L, and the concentration of ammonia nitrogen is 22500mg / L. The specific process is as follows:

[0044] 1) Add a mixed solution of sodium carbonate and sodium hydroxide to the above wastewater, and adjust the pH to 12. At this time, some cobalt carbonate and nickel carbonate precipitates are formed, and they are removed by a filter;

[0045] 2) Put the alkaline wastewater described in step 1) into the stripping tower for treatment; control the temperature of the stripping tower by controlling the steam flow rate and steam pressure input into the stripping tower, so that the temperature of the tower kettle is 115 °C, and the temperature at the top of the tower kettle is 10m The temperature is 106°C;

[0046] 3) Adjust the flow rate of waste water through the spacing of the multi-stage trays in the stripping tower, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com