Preparation method and application of high-purity polysaccharopeptide

A Yunzhi glycopeptide, a high-purity technology, is applied in the preparation methods of peptides, chemical instruments and methods, medical preparations containing active ingredients, etc., and can solve the problem of no reports of livestock and poultry vaccine immune enhancers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

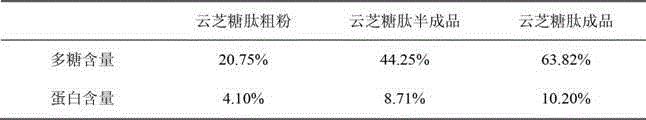

[0020] Example 1 Extraction and Purification of Yunzhi Glycopeptide

[0021] Take Yunzhi glycopeptide coarse powder 1kg, add 6% (w / v) NaHCO according to the ratio of material to water 1:48 3 Aqueous solution, heated to 70-72°C, heat-preserved and leached for 2 hours, centrifuged at 5500rpm, the supernatant was taken, heated to 75°C, heat-preserved and concentrated 9 times, then added 6 times the volume of absolute ethanol, static at 1-3°C After 24 hours, centrifuge at 4500rpm, discard the supernatant, wash the precipitate twice with 95% ethanol, absolute ethanol, acetone, and ether (4000rpm, 5min), and dry to obtain 492.5g of semi-finished versicolor glycopeptide.

[0022] Take 500g of Yunzhi glycopeptide semi-finished product, add double distilled water to dissolve, then add 0.25 times the volume of organic solvent, the organic solvent is chloroform and n-butanol with a volume ratio of 5:1, vigorously shake and mix for 20 minutes, and centrifuge at 4500rpm for 10 minutes , t...

Embodiment 2

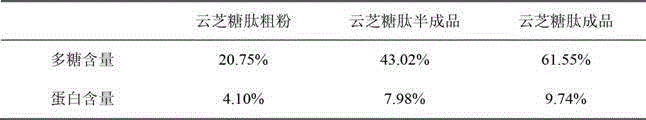

[0026] Example 2 Extraction and Purification of Yunzhi Glycopeptide

[0027] Take Yunzhi glycopeptide coarse powder 1kg, add 8% (w / v) NaHCO according to the ratio of material to water 1:40 3 Aqueous solution, heated to 70-72°C, heat-preserved and leached for 1.5h, centrifuged at 6000rpm, took the supernatant, heated to 78°C and concentrated 8 times, then added 5 times the volume of absolute ethanol, in the environment of 1-3°C After standing for 20 hours, centrifuge at 5000rpm, discard the supernatant, wash the precipitate twice with 95% ethanol, absolute ethanol, acetone, and ether (4000rpm, 5min), and dry to obtain 489.8g of semi-finished versicolor glycopeptide.

[0028] Take 500g of Yunzhi glycopeptide semi-finished product, add double distilled water to dissolve, then add 0.2 times the volume of organic solvent, the organic solvent is chloroform and n-butanol with a volume ratio of 5:1, shake vigorously for 15 minutes, and centrifuge at 4500rpm for 10 minutes , take the ...

Embodiment 3

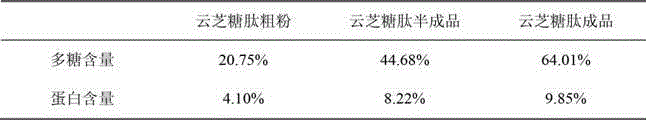

[0032] Example 3 Extraction and Purification of Yunzhi Glycopeptide

[0033] Take Yunzhi glycopeptide coarse powder 1kg, add 7% (w / v) NaHCO according to the ratio of material to water 1:55 3 Aqueous solution, heated to 70-72°C, heat preservation and leaching for 2.5h, centrifuged at 5000rpm, take the supernatant, heat to 78°C, heat preservation and concentrate 10 times, then add 7 times the volume of absolute ethanol, in the environment of 1-3°C After standing for 30 hours, centrifuge at 4500rpm, discard the supernatant, wash the precipitate twice with 95% ethanol, absolute ethanol, acetone, and ether (4000rpm, 5min), and dry to obtain 485.0g of semi-finished versicolor glycopeptide.

[0034] Take 500g of Yunzhi glycopeptide semi-finished product, add double distilled water to dissolve, then add 0.3 times the volume of organic solvent, the organic solvent is chloroform and n-butanol with a volume ratio of 5:1, vigorously shake and mix for 25 minutes, and centrifuge at 5000rpm fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com