Sealing ring for bottom and top cover of filter cleaner

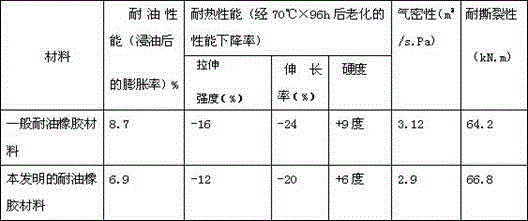

A filter and sealing ring technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems affecting the normal use of the filter, poor surface finish, high thermal deformation coefficient, and achieve enhanced rigidity and hardness. , The effect of strong wear resistance and low thermal deformation coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A sealing ring for filter bottom shell and upper cover, which is composed of the following raw materials in parts by weight: neoprene CR121 55, hydrogenated nitrile rubber ZP2020 (Japan Zion) 50, zinc stearate 2 , Coumarone 8, 2-mercaptobenzimidazole 1, chlorinated paraffin 4, semi-reinforcing carbon black SRF 110, montmorillonite powder 20, adipate 2, accelerator PZ 1, accelerator TETD 1, Cross-linking agent TAC 1.8, anti-aging agent RD 0.8, antioxidant 1010 2, modified diatomaceous earth 1.

[0015] The preparation method of the sealing ring used for the filter bottom case and the upper cover includes the following steps:

[0016] (1) Prepare raw materials according to the raw material components of each weight part, put each raw material into an internal mixer, synthesize rubber through the internal mixer, and filter;

[0017] (2) Detect the filtered synthetic rubber, pass the qualified synthetic rubber through the open mill for kneading and molding, and then put th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com