Erbium doped yttrium trifluoride upconversion luminescence hollow nanometer fiber preparation method

A hollow nano, yttrium trifluoride technology, used in chemical instruments and methods, nanotechnology, luminescent materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

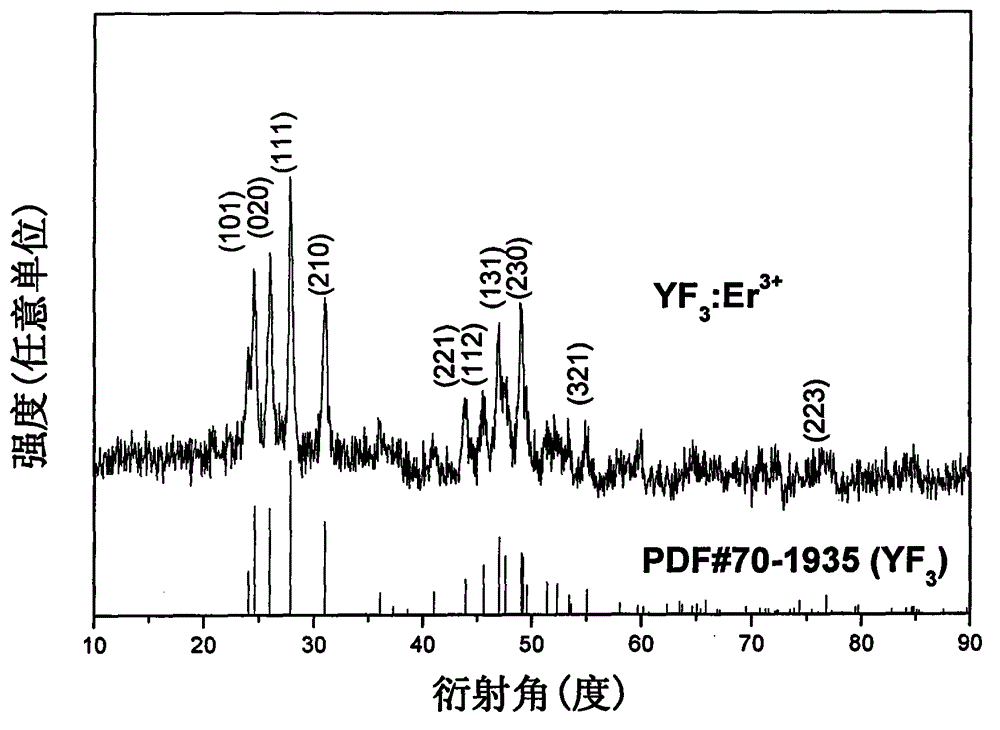

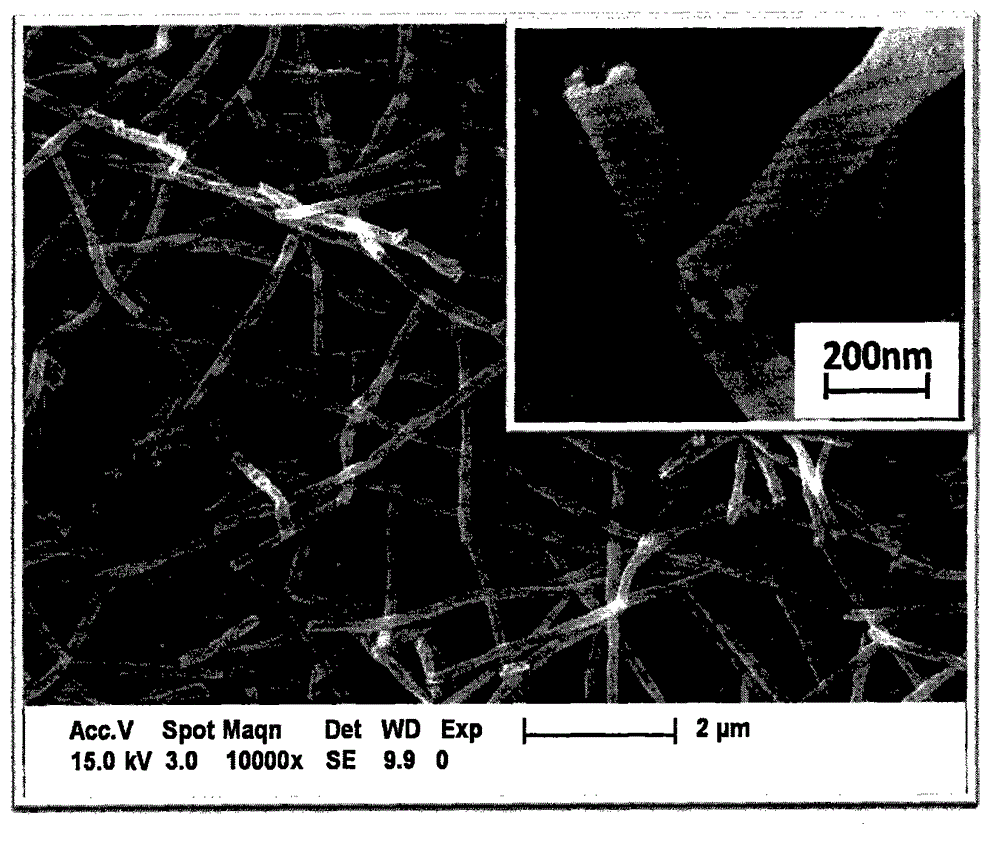

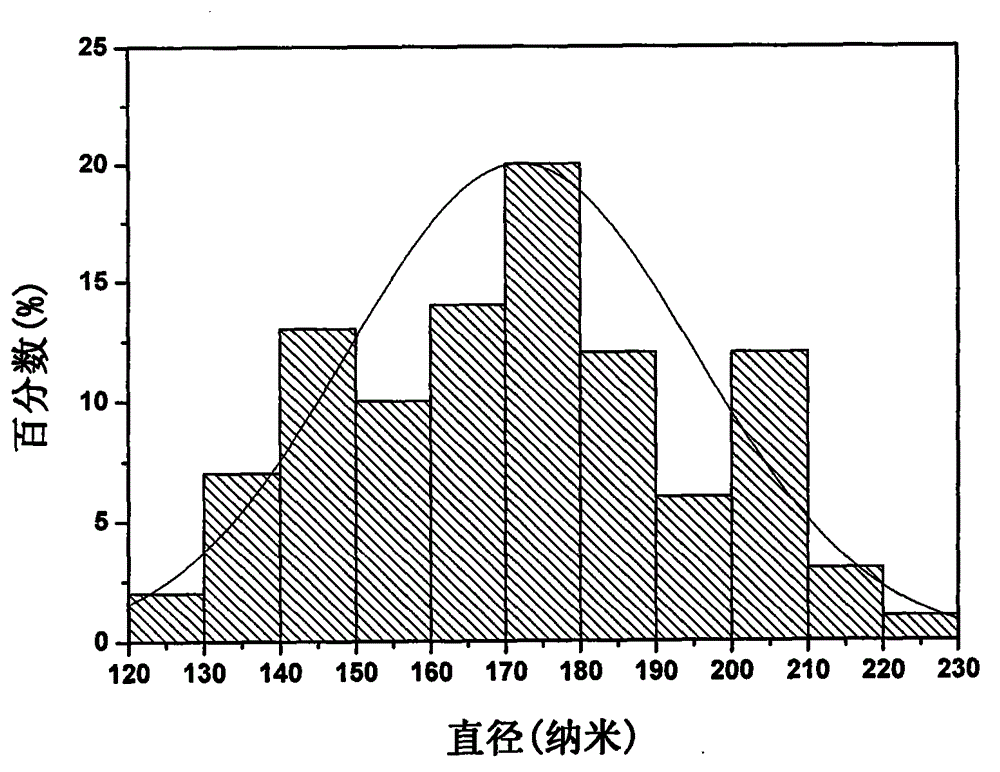

[0026] Embodiment: take a certain amount of yttrium oxide Y 2 o 3 and erbium oxide Er 2 o 3 , where Y 3+ and Er 3+ The molar ratio of erbium ions is 95:5, that is, the molar percentage of erbium ions is 5%. 3 Dissolved and evaporated to give Y(NO 3 ) 3 and Er(NO 3 ) 3 Mix the crystals, add DMF and PVP, stir magnetically at room temperature for 4 hours, and let stand for 2 hours to form a spinning solution. The mass percentages of each component in the spinning solution are: nitrate content 12%, PVP content 39%, solvent The DMF content is 49%; the uniaxial electrospinning technology is adopted, and the spinneret adopts a truncated 10# stainless steel injection needle with an outer diameter of 1.0mm and an inner diameter of 0.7mm, and the prepared spinning solution is placed in the spinning device In the liquid storage pipe, the vertical spraying method is adopted, the spinneret is perpendicular to the horizontal plane, the DC voltage is adjusted to 16kV, the curing dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com