Mash gas incineration system with metal fibre burner

A metal fiber, combustion system technology, applied in burners, gas fuel burners, combustion methods, etc., can solve the problems of high price, high equipment cost, short service life, etc. glitch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the objectives, technical solutions and advantages of the present invention clearer, the preferred embodiments of the present invention will be described in detail below.

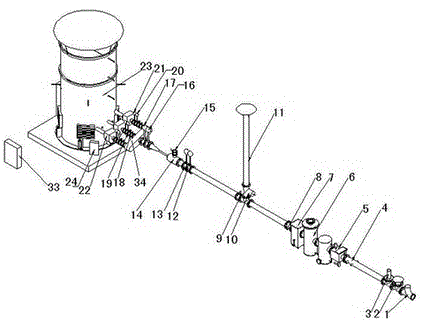

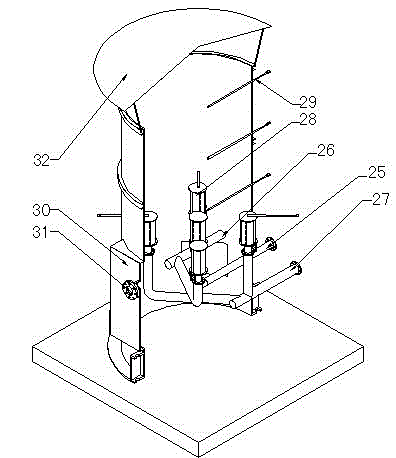

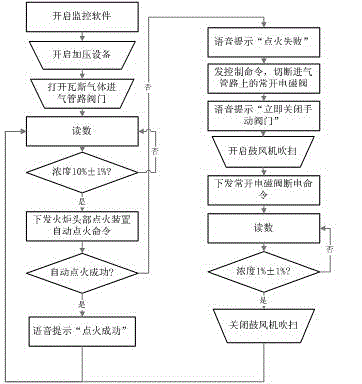

[0023] Such as figure 1 Shown is a structural schematic diagram of a gas incineration system with a metal fiber burner according to the present invention; figure 2 Shown as figure 1 The internal structure diagram of the torch incinerator shown in image 3 Shown is a flow chart of the operation of a gas incineration system with a metal fiber burner of the present invention; a gas incineration system with a metal fiber burner of the present invention includes a torch incinerator 23, a gas transportation safety guarantee system, and an air supply system , Automatic ignition device and PLC control system, the torch incinerator 23 is provided with no less than one set of combustion system, and each set of combustion system includes no less than one piece of metal fiber burner 28;

[0024] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com