Preparation method of wide-forbidden-band semiconductor flexible substrate

A wide-bandgap semiconductor and flexible substrate technology, applied in the field of microelectronics, can solve the problems of high manufacturing cost and small crystal size, and achieve the effect of improving crystal quality, large substrate size, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

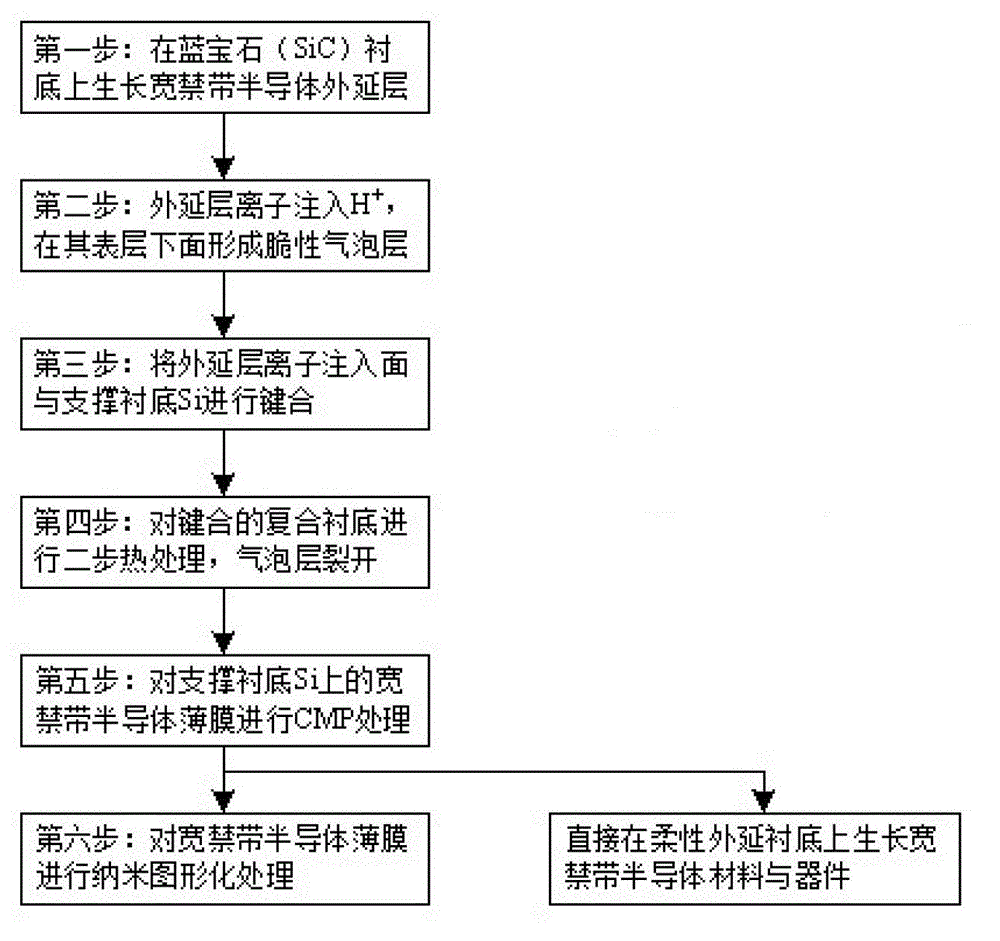

[0032] A method for preparing a large-scale SiC homoepitaxial flexible substrate such as Figure 1 to Figure 6 As shown, the thickness of the SiC flexible functional layer is 20~50nm. The LED device with vertical structure can be prepared on the flexible substrate, which not only saves the cost, but also improves the light-emitting area and performance of the device.

[0033] Concrete preparation steps are as follows:

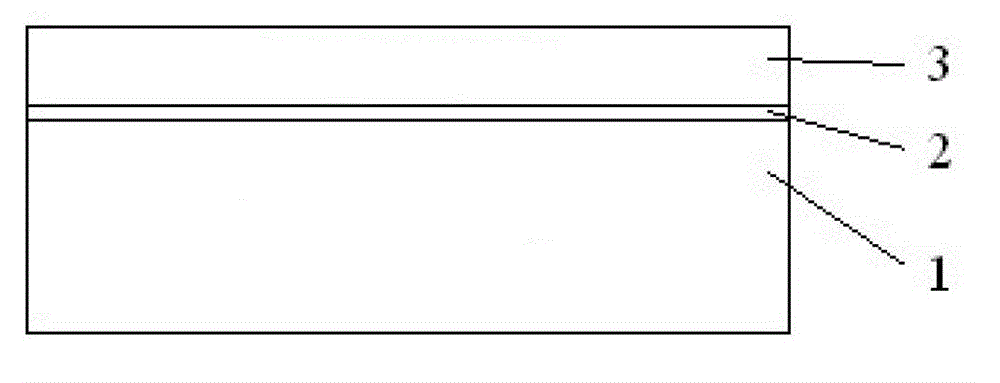

[0034] 1) The SiC epitaxial layer 3 is grown on the SiC or Si substrate 1 by high-temperature MOCVD, MBE and other technologies. There is a buffer layer 2 between the SiC epitaxial layer 3 and the SiC or Si substrate 1. The size of the SiC or Si substrate 1 is 2~6inch. A SiC thick film with low micropipe density is prepared by step-controlled epitaxy or position-competitive epitaxy, and the thickness of the thick film ranges from 5 μm to 10 mm.

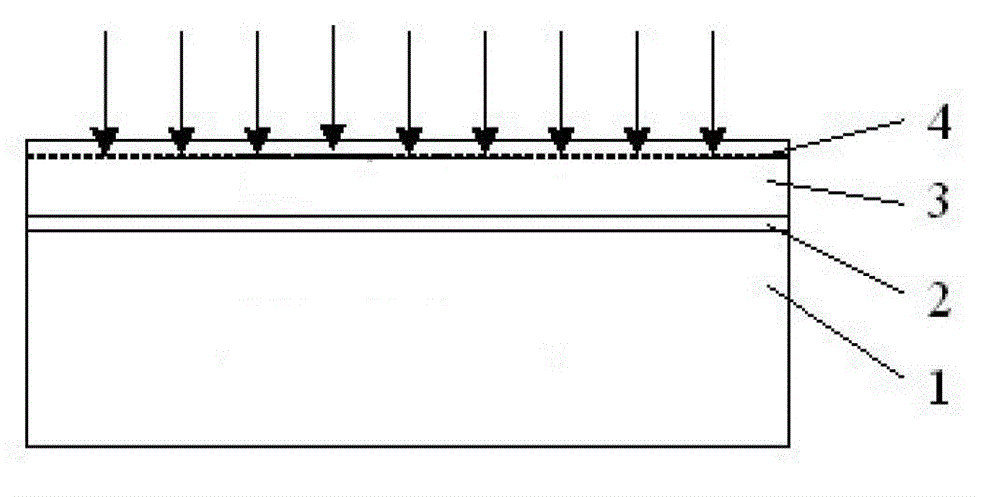

[0035] 2) Perform H on the upper surface of SiC epitaxial layer 3 + implanted to form a brittle bubble layer 4 i...

Embodiment 2

[0040] A method for preparing a large-scale patterned GaN homoepitaxial flexible substrate such as Figure 1 to Figure 7 As shown, the thickness of the GaN flexible functional layer is 20~50nm. The LED device with vertical structure can be prepared on the flexible substrate, which not only saves the cost, but also improves the light-emitting area and performance of the device.

[0041] Concrete preparation steps are as follows:

[0042] 1) GaN epitaxial layer 3 is grown on sapphire or SiC substrate 1 by MOCVD, MBE or HVPE technology, and there is a buffer layer or superlattice 2 between GaN epitaxial layer 3 and sapphire or SiC substrate 1, SiC or Si substrate The size of 1 is 2~8inch. Using the most advanced MOCVD, MBE or HVPE technology, including buffer layer technology, superlattice technology, ELOG technology, etc. to prepare a dislocation density of 10 5 ~10 6 cm -2 GaN thick film, the thickness of the thick film ranges from 5μm to 10mm.

[0043] 2) Perform H on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com