Process of direct copper exchange into na+-form of chabazite molecular sieve, and catalysts, systems and methods

A molecular sieve and catalyst technology, applied in the field of copper-containing molecular sieves, can solve the problems of increasing the capital and operating costs of the preparation method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

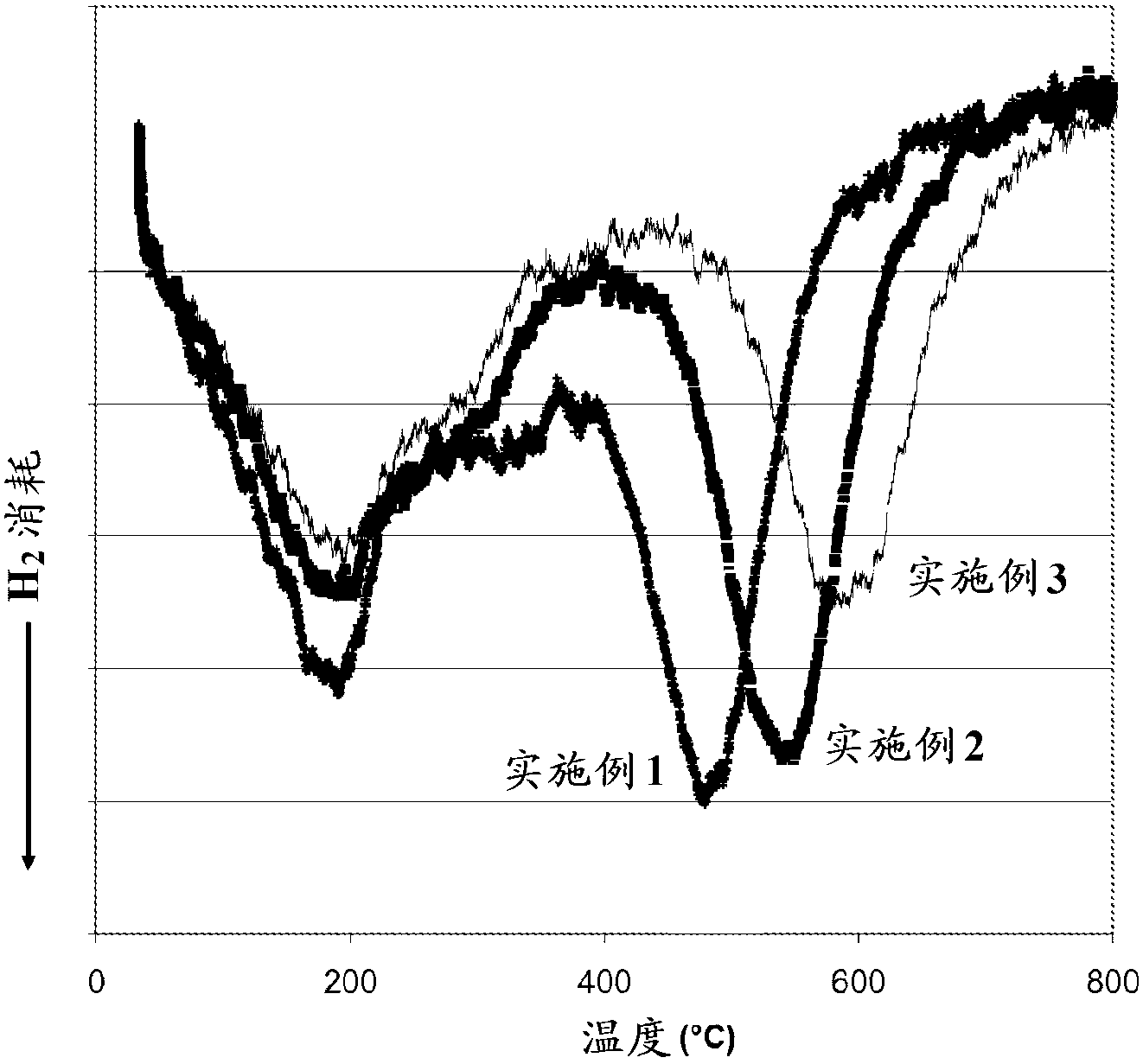

[0146] h 2 -TPR Spectrum

[0147] h 2 Temperature programmed reduction (TPR) measurements were performed on a Micromeritics Autochem 2910 analyzer with TCD detector. Pretreated at 4% O 2 He was carried out at a rate of 20°C / min from room temperature to 500°C with a residence time of 20 minutes. The samples were then cooled to room temperature. After this, it was purged under helium for 10 min. TPR at 0.5%H 2 / N 2 The process was carried out at a rate of 10°C / min from room temperature to 900°C with a residence time of 20 minutes. A liquid helium cold trap was used during the reduction. UV-VIS

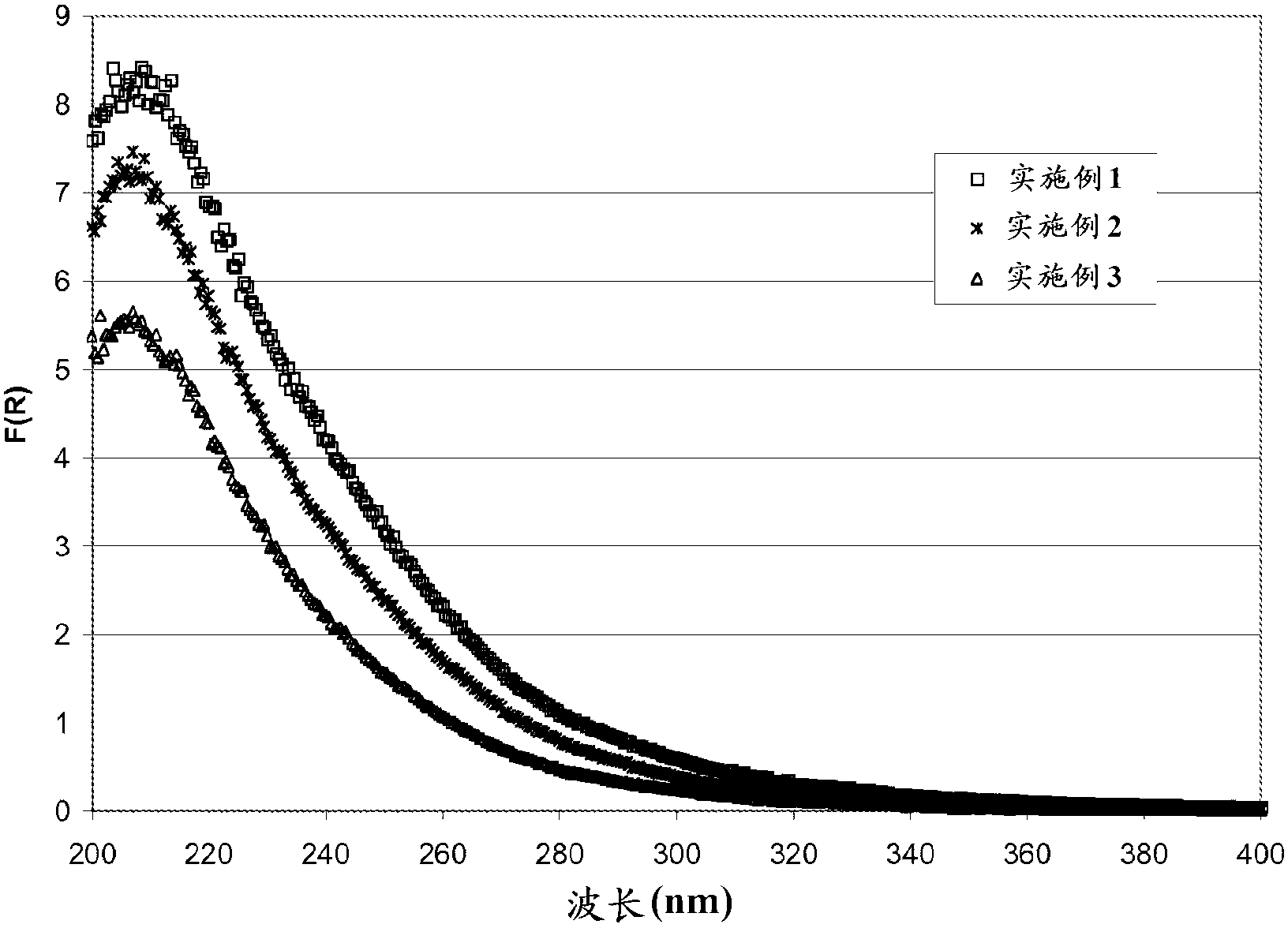

[0148] The samples were ground by hand using a mortar and pestle and then filled into 0.2 cm quartz cuvettes. Diffuse reflectance UV-VIS spectra, expressed as F(R), were collected using diffuse reflectance in a Cary 300UV-VIS spectrometer, where the connection is useful for BaSO 4 Coated integrative spheres. Use the following instrument parameter settings:

[0149] Scan rate...

Embodiment 1

[0165] Embodiment 1—raw material Na-SSZ13

Embodiment 1A

[0166] Embodiment 1A—raw material Na-SSZ13 (1)

[0167] SSZ-13 was crystallized as described in US 4,544,538 using trimethyladamantyl ammonium hydroxide as a template and sodium hydroxide as the other OH source. The pH value was adjusted to 7.5, and the material was recovered by filtration and dried, followed by calcination at 600 °C to prepare Na-form SSZ-13.

[0168] Chemical analysis indicated that the material has 31.8SiO 2 :Al 2 o 3 and 0.62% by weight Na on a non-volatile basis 2 O. XRD indicated that pure SSZ-13 was obtained. The BET surface area of the calcined material determined according to DIN 66131 is 663m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com