Preparation method of ZnO / g-C3N4 composite photocatalyst

A photocatalyst, g-c3n4 technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as weak composite structure, easy formation of agglomerated structure, and reduced catalyst activity, so as to improve Activity, increased crystallinity, enhanced separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

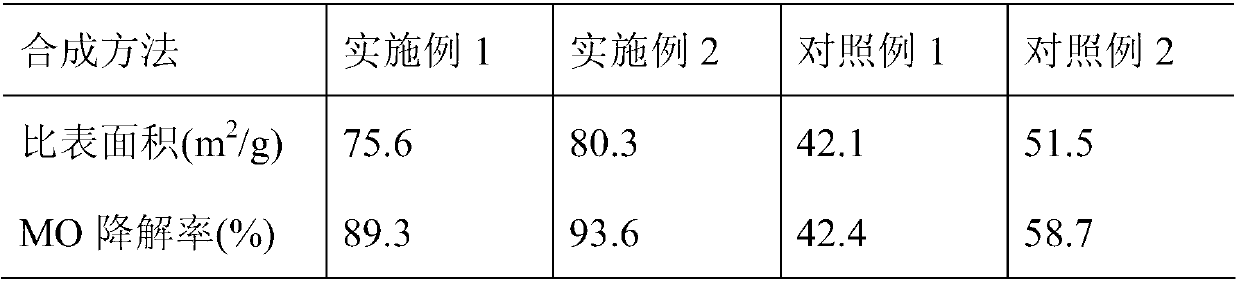

Embodiment 1

[0019] ZnO / g-C 3 N 4 The preparation adopts two-stage solvothermal-ultrasonic method. According to zinc acetate, ethanol, diethanolamine, g-C 3 N 4 Mass ratio = 1:10:20:1.5, mixed vigorously for 6 hours; then transferred the mixed system into a polytetrafluoroethylene-lined high-pressure reactor, reacted at 150°C for 24h, and at 190°C for 24h; after that, filtered, Ultrasonic dispersion (frequency 40KH Z , the power is 300W), washing, and repeating four times, the filter cake is dried and calcined at 500° C. for 2 h in an air atmosphere; it is ground into powder after cooling.

Embodiment 2

[0021] ZnO / g-C 3 N 4 The preparation adopts two-stage solvothermal-ultrasonic method. ZnO / g-C 3 N 4 Preparation according to zinc acetate, ethanol, diethanolamine, g-C 3 N 4 Mass ratio = 1:15:20:2.0, mixed vigorously for 8 hours; then transferred the mixed system into a polytetrafluoroethylene-lined high-pressure reactor, reacted at 130°C for 30h, and reacted at 180°C for 18h; then filtered, Ultrasonic dispersion (frequency 40KH Z , the power is 600W), washing, and repeating four times, the filter cake is dried and calcined at 500° C. for 1 h in an air atmosphere; it is ground into powder after cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com