Preparation method of nano zinc oxide rod

A technology of nano-zinc oxide and zinc acetate, applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, etc., can solve the problems of large amount of template agent, pollution, lack of diversity of templates, etc., and achieves simple method, small amount and dispersion. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

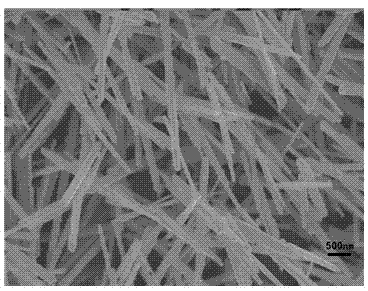

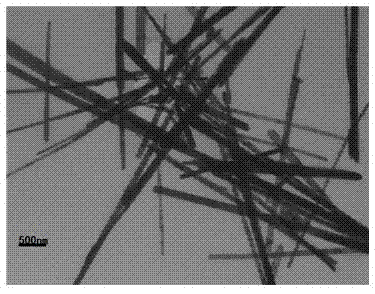

[0019] Weigh 1.6gZn(AC) 2 2H 2 O, dissolve in 40ml of distilled water, stir to dissolve completely, add 4mol / L NaOH dropwise until the precipitate disappears completely, add 10mL of anionic polyacrylamide with a concentration of 1g / L and a molecular weight of 6 million as a template agent, and disperse with high shear Stir at 2500r / min for 10min, pour into a Teflon-lined reactor, and react at 180°C for 2 hours. Cool, filter, fully wash with distilled water and absolute ethanol, and dry at 80°C to obtain nano zinc oxide rods. The obtained rod-shaped nano zinc oxide has an average diameter of 94nm and an average length of 0.7um.

Embodiment 2

[0021] Weigh 0.8gZn(AC) 2 2H 2 O, dissolve in 40ml of distilled water, stir to dissolve completely, add 5mol / L NaOH dropwise until the precipitate disappears completely, add 15ml of cationic polyacrylamide with a concentration of 1g / L and a molecular weight of 8 million as a template agent, and use high shear Dispersion mode Stirring at a speed of 1500r / min for 30min, pouring into a polytetrafluoroethylene-lined reactor, and reacting at 100°C for 24 hours. Cool, filter, fully wash with distilled water and absolute ethanol, and dry at 90°C to obtain nano zinc oxide rods. The obtained rod-shaped nano zinc oxide has an average diameter of 30nm and an average length of 13.3um.

Embodiment 3

[0023] Weigh 1.2gZn(AC) 2 2H 2 O, dissolve in 30ml of distilled water, stir to dissolve completely, add 4mol / L NaOH dropwise until the precipitate disappears completely, add 5ml of anionic polyacrylamide with a concentration of 1.5g / L and a molecular weight of 4 million as a template agent, and use high shear Dispersion mode Stir at 2000r / min for 15min, pour into a polytetrafluoroethylene-lined reactor, and react at 130°C for 10 hours. Cool, filter, fully wash with distilled water and absolute ethanol, and dry at 90°C to obtain nano zinc oxide rods. The obtained rod-shaped nano zinc oxide has an average diameter of 56nm and an average length of 4.7um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com