Ultraviolet light monomer compound and preparation method thereof, polymerizable composition, backlight module and liquid crystal display

A technique for polymerizing compositions and compounds, which is applied in the preparation of organic compounds, chemical instruments and methods, and preparation of carboxylate esters. The effect of good luminance value and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073]The preparation method of the polymerization composition provided by the present invention can be obtained directly by mixing each component in the composition. In preferably, in order to shorten the mixing time, mixing is preferably at 40 ° C-80 ° C.

[0074] The invention also provides a backlight module, which includes a brightening film, which is a brightening film formed by the cingering of polymerization combinations as described above.It can be coated with a polymerized pair of polytinate (PET) to form a coating with prism patterns by applying a polytarbinic acid ethyl (PET), which can be obtained.The brightening film formed by the aggregate composition.Then, the backlight module is made by combining with conventional components including lamps, light guide boards, and other known optical membranes.According to the embodiments of the present invention, the thickness of the brighter membrane is 15-25 microns, preferably, and the thickness of the bright film is 20 micro...

Embodiment 1-4

[0078] The raw materials used in Example 1-4 are as follows:

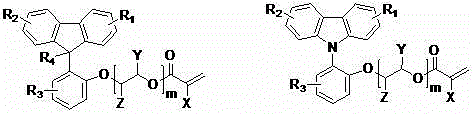

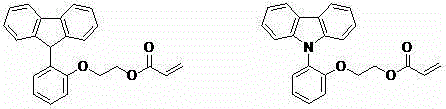

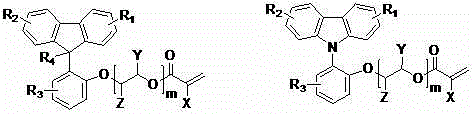

[0079] (A): Type I 1 The monomer compounds shown:

[0080] Will Heated to the nitrogen protection in the DMF to the reaction of nitrogen protection to 80 ° C for 5 hours, and then add the production product, and then add acrylic acid to a toluene to the 75 ° C to return to the return reaction for 2 hours to obtain the compound shown in the type I1;

[0081] (B): Light Treaster I173 (purchased from Steam Performance Company);

[0082] (C): The cross -linked agent SR294 (purchased from Sartomer);

[0083] (D): diluent PBA-001 (purchased from Shanghai to Germany chemistry);

[0084] Prepare the raw materials in Table 1, mix the above raw materials together, and heat it at 50 ° C until it forms a uniform and transparent colloidal polymer.Apply the above -mentioned preparation of glue polymer to the polypenic acid ethyl (PET) substrate (PET) substrate (PET).The thickness of 20 microns is brightened.

[0085] Table 1

[008...

Embodiment 5-8

[0091] The raw materials used in Example 5-8 are as follows:

[0092] (A): Format II 1 Compounds:

[0093] Will Heated to the nitrogen protection in the DMF to the reaction of 8 hours under the protection of nitrogen to get the production product, and then add acrylic acid to a toluene to heated to 70 ° C to return to 5 hours, get the type II 1 The compound shown;

[0094] (B): Light cause i184 (1-hydroxyl cycloinylbenzetone);

[0095] (C): Cylinner SR351 (purchased from Sartomer)

[0096] (D): diluted agent PP-011 (phthaphyzenezhexyxyl ethyl acid ester)

[0097] Prepare the raw materials in Table 3, prepare the bright film and backlight module according to the same method of Example 1, and perform a bride test. The results are shown in Table 4.

[0098] table 3

[0099] (a) (gram) (B) (gram) (c) (gram) (d) (gram) Example 5 0.5 0.4 2.5 6.5 Example 6 1.0 0.4 2.5 6.0 Example 7 1.5 0.4 2.5 5.5 Example 8 2.0 0.4 2.5 5.0

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com