PE-RT (polyethylene of raised temperature resistance) composition and application thereof

A technology of heat-resistant polyethylene and composition, applied in the direction of hoses, mechanical equipment, pipes/pipe joints/fittings, etc., can solve the long-term performance deterioration of materials, no disclosure of product oxidation induction period, tensile yield stress performance, The types of antioxidants and the specific selected varieties are not disclosed, so as to achieve the effect of excellent long-term heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

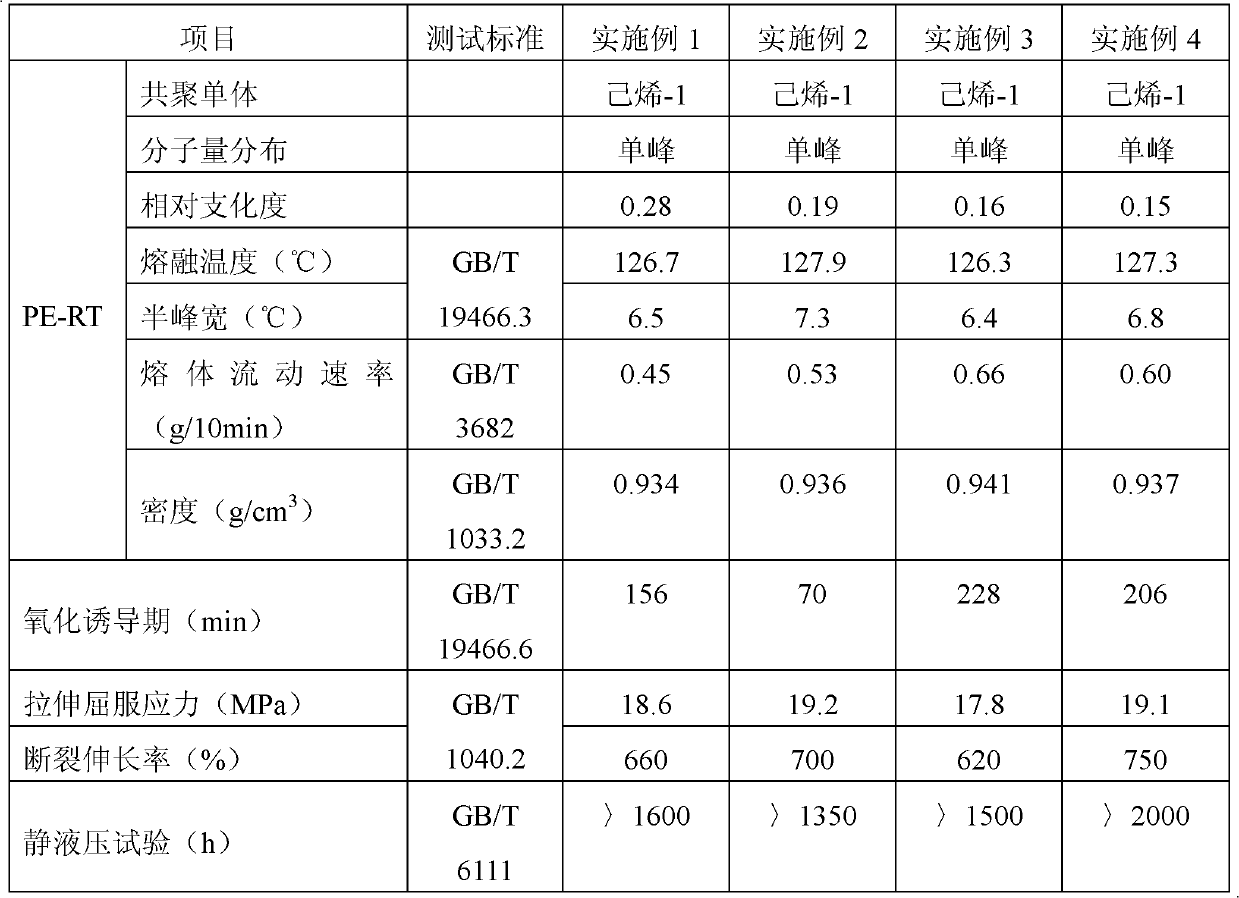

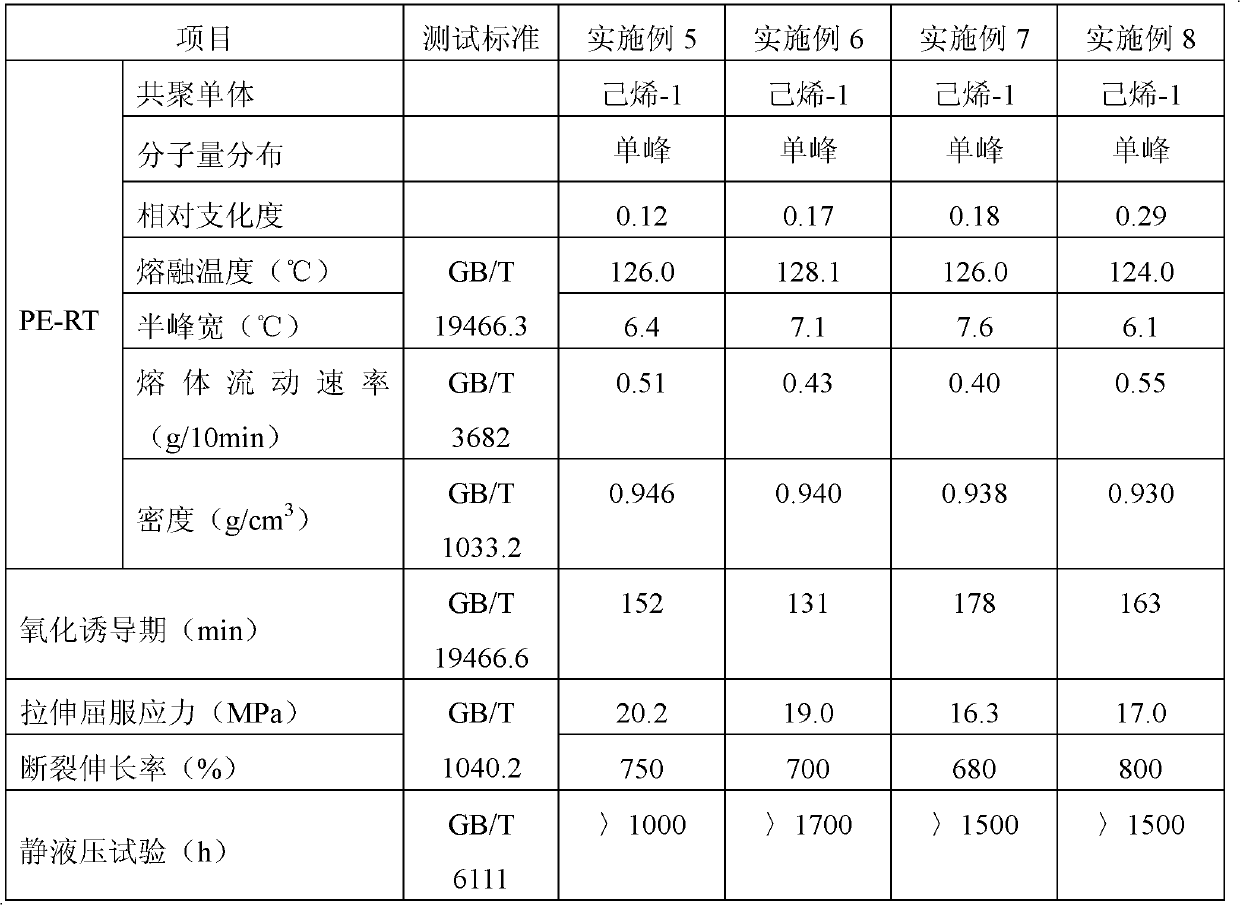

Embodiment 1

[0032] The heat-resistant polyethylene composition consists of 100 parts of PE-RT resin (MI=0.45g / 10min, density 0.934g / cm 3 ), 0.1 parts of tetrakis[β-(3,5 di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, 0.15 parts of 1,3,5-trimethyl-2,4,6-tri (3,5-di-tert-butyl-4-hydroxybenzyl)benzene, 0.15 parts of 1,3,5-tris(3,5-di-tert-butyl-4-hydroxybenzyl)-s-triazine-2,4 , 6-(1H, 3H, 5H) triketone and 0.1 parts of tris (2,4-di-tert-butylphenyl) phosphite.

[0033] The performance of the composition was measured according to the corresponding standards, and the performance parameters and the characteristics of the PE-RT used are shown in Table 1.1.

Embodiment 2

[0035] The heat-resistant polyethylene composition consists of 100 parts of PE-RT resin (MI=0.53g / 10min, density 0.936g / cm 3 ), 0.1 parts of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, 0.2 parts of tris(2,4-di-tert-butylphenyl) phosphite and 0.1 part of dilauryl thiodipropionate.

[0036] The performance of the composition was measured according to the corresponding standards, and the performance parameters and the characteristics of the PE-RT used are shown in Table 1.1.

Embodiment 3

[0038] The heat-resistant polyethylene composition consists of 100 parts of PE-RT resin (MI=0.66g / 10min, density 0.946g / cm 3 ), 0.2 parts of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, 0.1 part of tris(2,4-di-tert-butylphenyl) phosphite, 0.4 part of bis(octadecyl)thiodipropionate and 0.01 part of fluoroelastomer (rheological agent for commercial pipe materials).

[0039] The performance of the composition was measured according to the corresponding standards, and the performance parameters and the characteristics of the PE-RT used are shown in Table 1.1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com