Resin composite material and its preparation method and use

A resin composite material and thermoplastic resin technology, applied in the field of preparation and resin composite material, can solve the problems of limited reinforcement effect, small fiber length and diameter of natural fiber reinforced material, screw wear, etc., and achieve the effect of less defects and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Get 87 parts of polylactic acid resin, 2 parts of tetrakis{β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate} pentaerythritol ester, 5 parts of polycaprolactone, 2 parts of bis(2,2, 6,6-Tetramethyl-4-piperidinyl) sebacate, 2 parts polyethylene glycol, 2 parts decabromodiphenylethane were mixed in a medium speed mixer for 4 minutes, mixed and added to the twin screw In the extruder, extrude and granulate, the screw speed is 75r / min, and the extruder head temperature is 190°C.

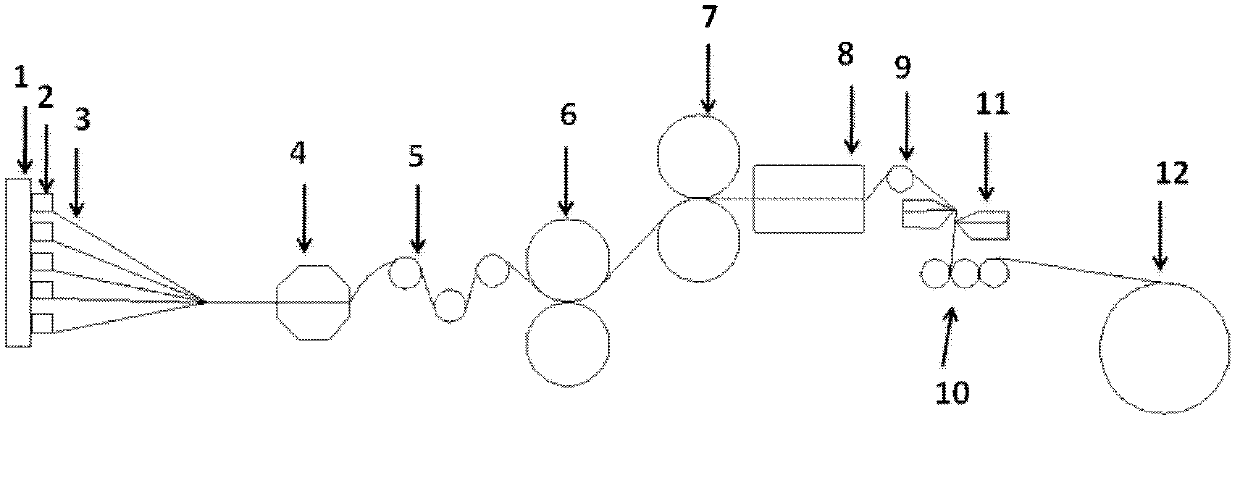

[0060] figure 1 It is a flow chart for the preparation of prepreg tapes of natural fiber / resin composites. The natural fiber used in this article refers to the long fiber length, which can be in a continuous state after twisting. The nominal count of a bundle of twisted fibers is 0.2-1; the cellulose content of natural fibers is ≥ 60%; the natural fibers are twisted After that, untwisting is carried out to form a loose and expanded form. Get 100 rolls of jute fiber thread through alkali treatmen...

Embodiment 2

[0062] Take 72 parts of homopolypropylene resin, 3 parts of dilauryl thiodipropionate, 10 parts of polycaprolactone, 3 parts of bis(2,2,6,6-tetramethyl-4-piperidinyl)decane Diacid ester, 3 parts low molecular weight polyethylene, 5 parts tetrabromobisphenol A bis(2,3-dibromopropyl) ether, 1 part 3-mercaptopropionate isooctyl, mix in a medium speed mixer for 4 Minutes, mixed and added to a twin-screw extruder, extruded and granulated, the screw speed was 75r / min, and the extruder head temperature was 190°C.

[0063] The natural fibers used in this example refer to those with longer fiber lengths, which can be in a continuous state after being twisted. The nominal count of a bundle of twisted fibers is 0.2 to 1; the cellulose content of natural fibers is ≥ 60%; the natural fibers After twisting, untwisting is performed to form a loose and expanded form. 100 volumes of alkali-treated jute fiber threads are pulled to the cord fabric loom, and the warp is polypropylene fiber, whic...

Embodiment 3

[0065] Take 95 parts of homopolypropylene resin, 3 parts of tetrabromobisphenol A bis(2,3-dibromopropyl) ether, and 2 parts of low molecular weight polyethylene. Mix in a medium-speed mixer for 4 minutes, add to a twin-screw extruder after mixing, extrude and granulate, the screw speed is 75r / min, and the extruder head temperature is 190°C.

[0066] The natural fibers used in this example refer to those with longer fiber lengths, which can be in a continuous state after being twisted. The nominal count of a bundle of twisted fibers is 0.2 to 1; the cellulose content of natural fibers is ≥ 60%; the natural fibers After twisting, untwisting is performed to form a loose and expanded form. 100 volumes of alkali-treated jute fiber threads are pulled to the cord fabric loom, and the warp is polypropylene fiber, which is woven into a cord fabric with a width of 1m; the tension is unfolded by the tension control device, and the natural fiber is pressed and rolled The roller is compac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com