Method for removing fluorine in bastnaesite sulfuric acid leaching liquid by using zirconium-containing adsorbent

A technology of bastnaesite and adsorbent, applied in the field of rare earth hydrometallurgy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

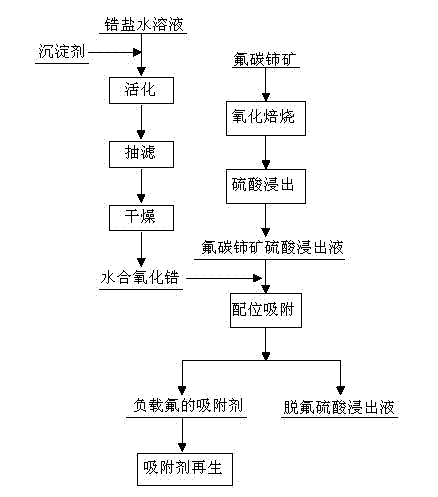

Method used

Image

Examples

Embodiment 1

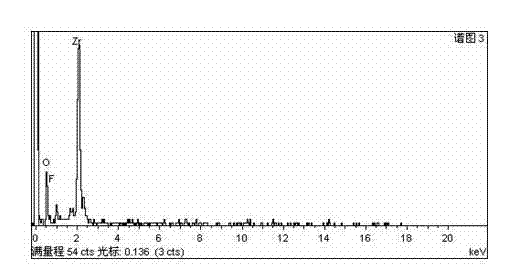

[0030] (1) ZrOCl 2 Dissolve in water to prepare 0.1mol L -1 solution, add 0.1mol·L while stirring -1 NaOH solution was used as a precipitating agent, and the pH was adjusted to 9. After the white precipitate was formed, it was stirred and activated at 65°C for 4h, and then filtered with suction. The obtained solid product was washed with distilled water until it was neutral, and dried at 100°C for 4h to obtain a zirconium-containing adsorbent. hydrated zirconia;

[0031] (2) The bastnaesite was oxidized and roasted at 400°C for 4 hours, and the concentration of 0.5mol L was added to the oxidized and roasted bastnaesite -1 sulfuric acid, leached at 50°C for 4h, the liquid-solid weight ratio of sulfuric acid to bastnaesite was 5:1, to obtain bastnaesite sulfuric acid leaching solution;

[0032](3) Dilute bastnaesite sulfuric acid leaching solution with water 10 times, where F - The concentration is 4.3×10 -3 mol L -1 , Ce 4+ The concentration is 2.6×10 -3 mol L -1 , RE ...

Embodiment 2

[0036] (1) ZrO(NO 3 ) 2 Dissolve in water to make 0.05mol·L -1 solution, add 0.05mol·L while stirring -1 NaOH solution was used as a precipitating agent, and the pH was adjusted to 10. After the white precipitate was formed, it was stirred and activated at 75°C for 2h, and then filtered with suction. hydrated zirconia;

[0037] (2) The bastnaesite was oxidized and roasted at 500°C for 3 hours, and the concentration of 2.0mol L was added to the oxidized and roasted bastnaesite -1 sulfuric acid, leached at 65°C for 2h, the liquid-solid weight ratio of sulfuric acid to bastnaesite was 10:1, to obtain bastnaesite sulfuric acid leaching solution;

[0038] (3) Dilute bastnaesite sulfuric acid leaching solution with water 30 times, where F - The concentration is 7.23×10 -3 mol L -1 , Ce 4+ The concentration is 4.96×10 -3 mol L -1 , RE 3+ The concentration is 7.4×10 -3 mol L -1 , adjust the acidity to 1mol L -1 , adding 1.0 g / 50 ml of the prepared zirconium-containing ad...

Embodiment 3

[0042] (1) ZrCl 4 Dissolve in water to prepare 0.5mol L -1 solution, add 0.5mol L while stirring -1 The ammonia solution was used as a precipitating agent, and the pH was adjusted to 10. After the white precipitate was formed, it was stirred and activated at 100 ° C for 1 h, and then filtered with suction. hydrated zirconia;

[0043] (2) The bastnaesite was oxidized and roasted at 800°C for 1 hour, and the concentration of 6.0mol L was added to the oxidized and roasted bastnaesite -1 Sulfuric acid was leached at 100°C for 0.5h, the liquid-solid weight ratio of sulfuric acid to bastnaesite was 1:1, and bastnaesite sulfuric acid leach solution was obtained;

[0044] (3) Dilute bastnaesite sulfuric acid leaching solution with water 100 times, where F - The concentration is 5.2×10 -3 mol L -1 , Ce 4+ The concentration is 2.89×10 -3 mol L -1 , RE 3+ The concentration is 5.02×10 -3 mol L -1 , adjust the acidity to 1mol L -1 , adding 0.4g / 50ml of the prepared zirconium-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com