Composite visible-light catalyst for TiO2 microsphere and g-C3N4, as well as preparation method and application of catalyst

A technology of g-c3n4 and visible light, applied in the direction of light water/sewage treatment, etc., can solve the problem of low activity and achieve the effects of simple preparation process, improved separation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Titanium sheet pretreatment: Titanium sheet pretreatment: Titanium sheet (length×width×thickness=48mm×15mm×0.16mm) was ultrasonically cleaned in acetone, isopropanol and ethanol for 15 minutes, and finally dried at 80°C , to obtain a clean titanium sheet.

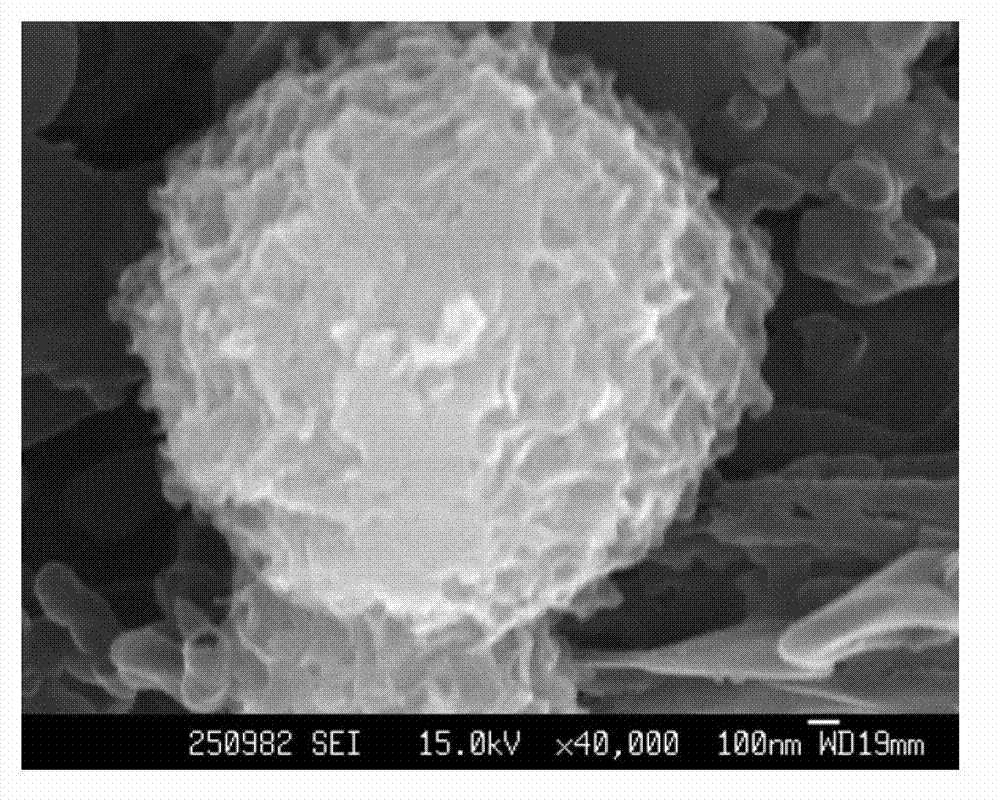

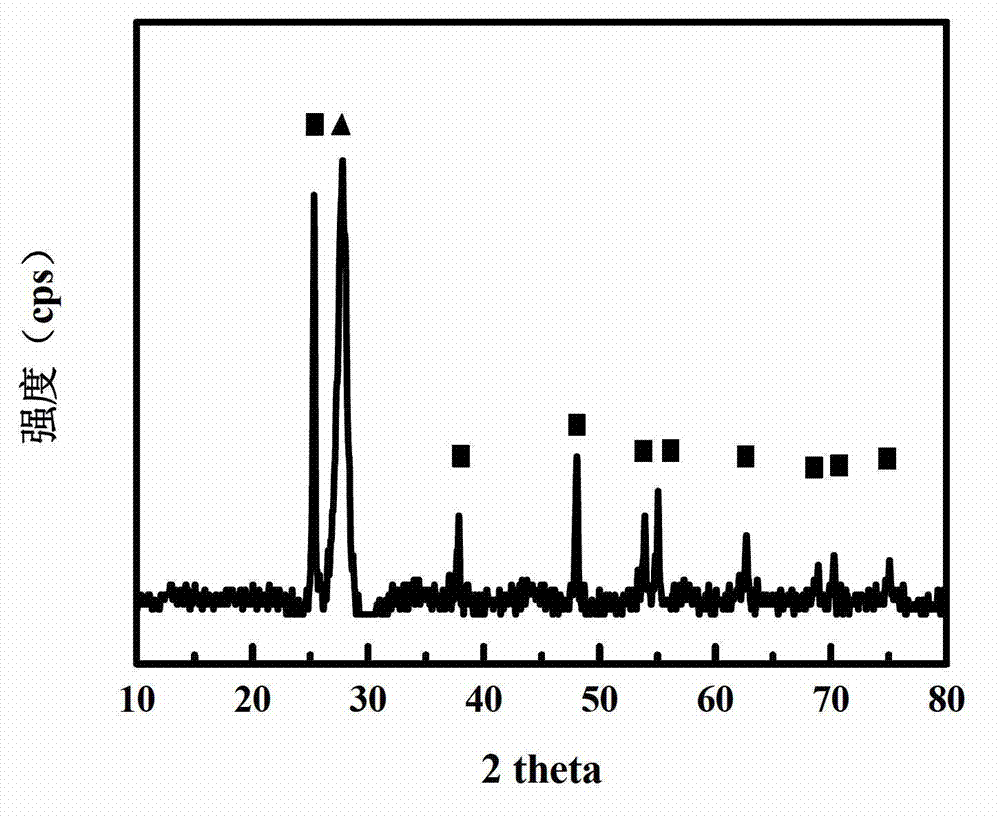

[0029] (2) Add 1.0g-melamine and 1.0g NH to 40mL deionized water 4 F, Ultrasonic the mixed system (frequency: 40kHz) for 30 minutes to obtain a milky white suspension mixed system, then transfer it to a 70mL autoclave, add a clean titanium sheet, seal it and react it hydrothermally at 150°C for 72 hours, collect the precipitate and use Wash with deionized water several times until neutral and dry at 80°C for 12h, then put into a crucible and seal with aluminum paper, heat up to 550°C at a rate of 20°C / min and keep for 4h, and cool naturally to room temperature to obtain the catalyst. Electron microscope detection: The prepared catalyst is detected by electron microscope, the results are as follows figure 1 As s...

Embodiment 2

[0033] (1) Titanium sheet pretreatment: the same as in Example 1, the only difference is that the size of the selected titanium sheet is length×width×thickness=10mm×10mm×0.05mm.

[0034] (2) Add 2.0g-melamine and 1.0g NH to 100mL deionized water 4 F. Ultrasonic the mixed system for 30 minutes to obtain a milky white suspension mixed system, then transfer it to a 70mL autoclave, and add a clean titanium sheet, seal it and react with water at 150°C for 48 hours, collect the precipitate and wash it with deionized water It was then neutralized and dried at 80°C for 12 hours, then put into a crucible and sealed with aluminum paper, heated to 550°C at a rate of 20°C / min and kept for 4 hours, and naturally cooled to room temperature to obtain the catalyst. It can be seen that the obtained product is TiO by scanning electron microscopy and XRD 2 Microspheres and g-C 3 N 4 of composite materials.

[0035] (3) Acyclovir degradation: with embodiment 1. The photocatalytic degradation...

Embodiment 3

[0038] (1) Same as Example 1, except that the size of the selected titanium sheet is length×width×thickness=5mm×5mm×0.5mm.

[0039] (2) Add 1.0g-melamine and 1.0g NH to 40mL deionized water 4 F. Ultrasonic the mixed system for 30 minutes to obtain a milky white suspension mixed system, then transfer it to a 70mL high-pressure reactor, and add a clean titanium sheet, seal it and react it with water at 150°C for 24 hours, collect the precipitate and wash it with deionized water It was then neutralized and dried at 80°C for 12 hours, then put into a crucible and sealed with aluminum paper, heated to 550°C at a rate of 20°C / min and kept for 4 hours, and naturally cooled to room temperature to obtain the catalyst. It can be seen that the obtained product is TiO by scanning electron microscopy and XRD 2 Microspheres and g-C 3 N 4 of composite materials.

[0040] (3) Acyclovir degradation: with embodiment 1. The photocatalytic degradation experiment results showed that the degra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com