Pentasil type zeolite molecular sieve synthetic method

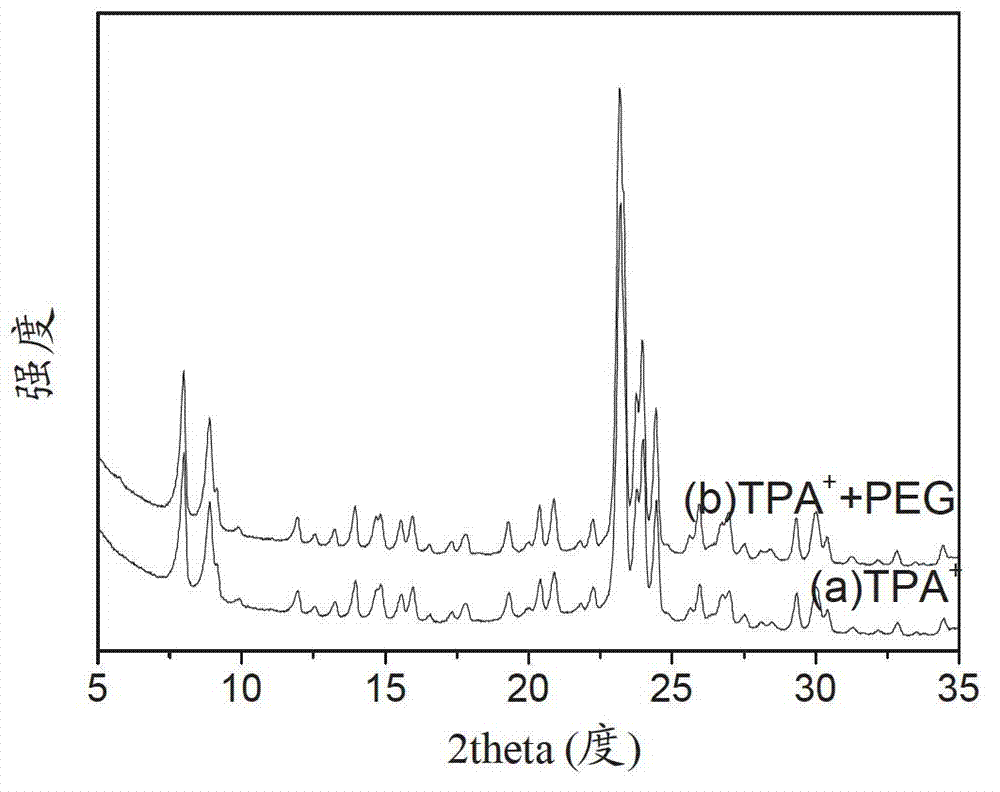

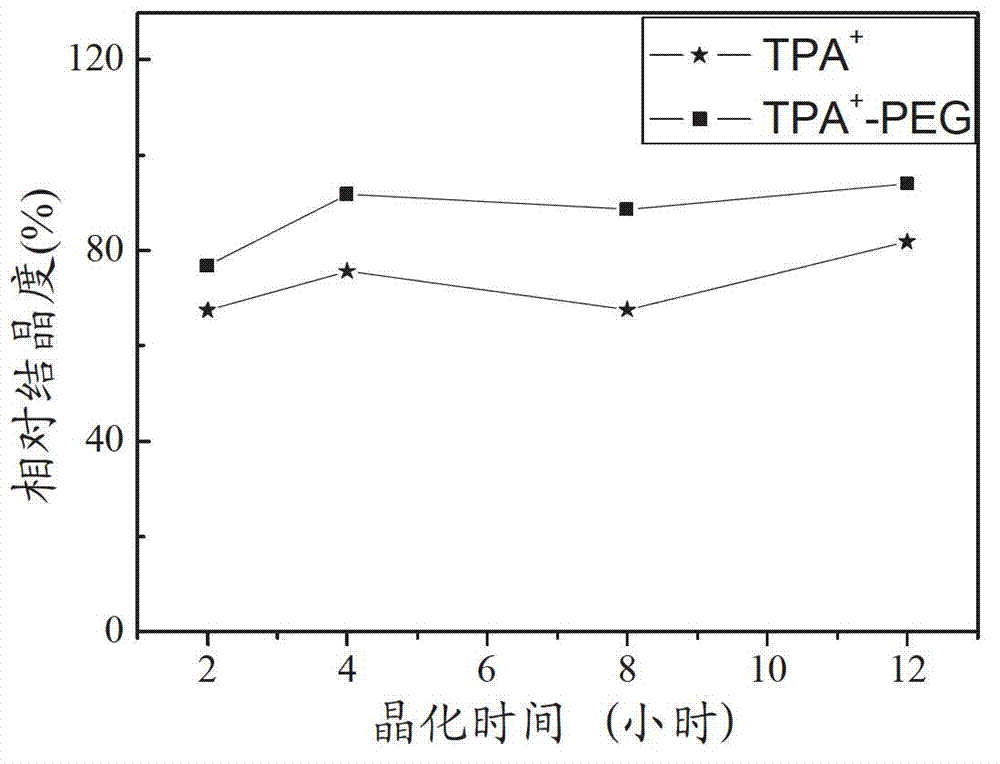

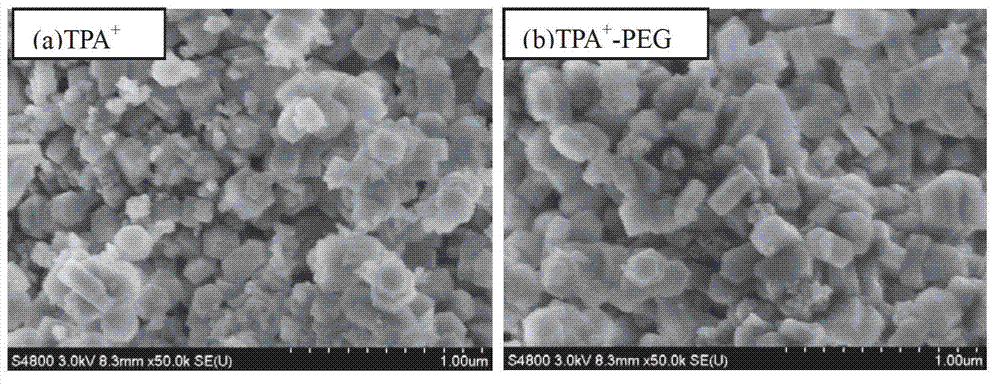

A zeolite molecular sieve and a synthesis method technology are applied in the directions of crystalline aluminosilicate zeolite, borocarbonane silicone crystalline aluminosilicate zeolite, etc. to achieve the effects of high crystallinity and purity, promotion of crystallization, and small amount of template agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of preparation method of pure silicon Silicalite-1 molecular sieve, its concrete steps are as follows:

[0036] (1) Dissolve solid NaOH with deionized water, stir and clarify, then add polyethylene glycol (PEG400) to form a clear solution; add solid silica gel to the above solution, stir for 30-60 minutes, and finally add TPA + guide glue, stir well. In the above reaction mixture, Al in the aluminum source compound 2 o 3 Molar equivalent: SiO 2 The molar equivalent of: alkali source compound: H 2 The molar ratio of O is 0:1:0.055:12. Of which SiO 2 : The mass ratio of guide glue: PEG400 is 1: 5%: 20%.

[0037] (2) Transfer the obtained reaction mixture to a high-pressure reactor for hydrothermal crystallization, and crystallize at 175°C for 12 hours. The crystallized product is filtered, washed with deionized water, dried, etc. to obtain pure silicon containing MFI structure Zeolite molecular sieve.

Embodiment 2

[0044] A kind of preparation method of silicon-aluminum ZSM-11 molecular sieve, its specific steps are as follows:

[0045] (1) Dissolve solid NaOH with deionized water, stir and clarify, then add polyethylene glycol (PEG400) to form a clear solution; add solid silica gel to the above solution, stir for 30-60 minutes, and finally add tetrabutylammonium hydroxide (TBAOH) , stir well. In the above reaction mixture, Al in the aluminum source compound 2 o 3 Molar equivalent: SiO 2 The molar equivalent of: alkali source compound: TBAOH: H 2 The molar ratio of O is 0:1:0.055:0.2:12. Of which SiO 2 The mass ratio of :PEG400 is 1:20%.

[0046] (2) Transfer the obtained reaction mixture to a high-pressure reactor for hydrothermal crystallization, and crystallize at 175°C for 24 hours. The crystallized product is filtered, washed with deionized water, dried, etc. to obtain pure silicon with MEL structure Zeolite molecular sieve.

Embodiment 3

[0052] A kind of preparation method of pure silicon Silicalite-1 molecular sieve, its concrete steps are as follows:

[0053] (1) dilute concentrated sulfuric acid to form dilute sulfuric acid solution A; meanwhile, dissolve sodium silicate nonahydrate (Na 2 SiO 3 9H 2 O) Formation of a clear B solution. Under mechanical stirring, add the clear solution A dropwise to the solution B. After the acid is completely added dropwise, filter the above turbid solution to obtain an amorphous filter cake, and feed the filter cake according to the following formula. Aluminum source compound Middle Al 2 o 3 Molar equivalent: SiO 2 The molar equivalent of: alkali source compound: H 2 The molar ratio of O is 0:1:0.055:35, and finally add TPA + Guide glue, stir for 30-60 minutes until uniform. Of which SiO 2: The mass ratio of guide glue: PEG400 is 1: 5%: 20%.

[0054] (2) Transfer the obtained reaction mixture to a high-pressure reactor for hydrothermal crystallization, and crystal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com