Preparation method of modified terminal-carboxyl-hyperbranched polyamide resin and paint containing resin

A polyamide resin and carboxyl-terminated technology, which is applied in the field of organic polymer compounds, can solve problems such as cracking and poor flexibility, and achieve high heat resistance, good flexibility, good acid resistance and water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Preparation of epoxy-terminated silicone oil

[0035] a) Formula

[0036] Octamethylcyclotetrasiloxane: 200g

[0037] Tetramethylammonium hydroxide: 0.1g

[0038] Concentrated sulfuric acid: 12g

[0039] Allyl glycidyl ether: 20g

[0040] Chloroplatinic acid: 0.1g

[0041] Toluene: 400g

[0042] b) Preparation process

[0043] After adding octamethylcyclotetrasiloxane, tetramethylammonium hydroxide and concentrated sulfuric acid to the reactor equipped with condenser, thermometer, dropping funnel and stirrer according to the ratio, the reaction was protected by nitrogen for 9h; the temperature was raised to 180 ℃, vacuum distillation to remove low-boiling substances to obtain hydrogen-terminated silicone oil; add hydrogen-terminated silicone oil, allyl glycidyl ether, toluene and chloroplatinic acid into the reactor; heat up to 90 ℃, nitrogen protection reaction for 10 hours, vacuum distillation The solvent is removed to obtain epoxy-terminated silicone oil.

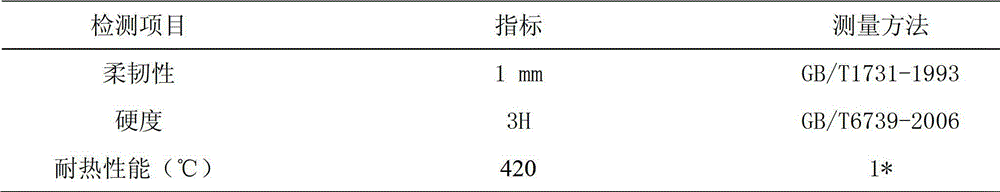

[0044] c) Performan...

Embodiment 2

[0074] 1) Preparation of epoxy-terminated silicone oil

[0075] a) Formula

[0076] Octamethylcyclotetrasiloxane: 200g

[0077] Tetramethylammonium hydroxide: 0.05g

[0078] Concentrated sulfuric acid: 6g

[0079] Allyl glycidyl ether: 11g

[0080] Chloroplatinic acid: 0.05g

[0081] Toluene: 320g

[0082] b) Preparation process

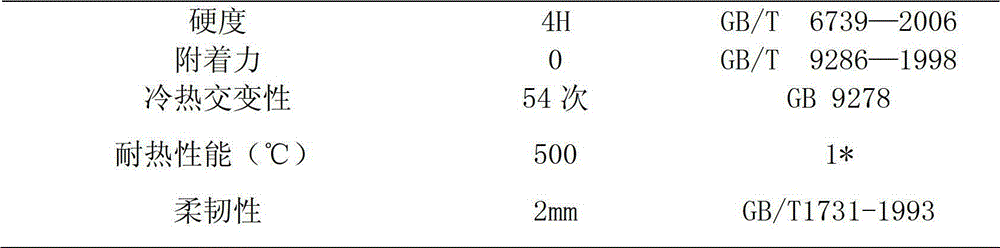

[0083] After adding octamethylcyclotetrasiloxane, tetramethylammonium hydroxide and concentrated sulfuric acid to the reactor equipped with condenser, thermometer, dropping funnel and stirrer in sequence according to the ratio, the reaction was protected by nitrogen for 8h; the temperature was increased to 180 ℃, vacuum distillation to remove low-boiling substances to obtain hydrogen-terminated silicone oil; add hydrogen-terminated silicone oil, allyl glycidyl ether, toluene and chloroplatinic acid into the reactor; increase the temperature to 85°C, and react under nitrogen protection for 8.5 hours. The solvent is distilled off to obtain epoxy-terminated silicon...

Embodiment 3

[0112] 1) Preparation of epoxy-terminated silicone oil

[0113] a) Formula

[0114] Octamethylcyclotetrasiloxane: 200g

[0115] Tetramethylammonium hydroxide: 0.03g

[0116] Concentrated sulfuric acid: 3g

[0117] Allyl glycidyl ether: 3g

[0118] Chloroplatinic acid: 0.02g

[0119] Toluene: 240g

[0120] b) Preparation process

[0121] After adding octamethylcyclotetrasiloxane, tetramethylammonium hydroxide and concentrated sulfuric acid to the reactor equipped with condenser, thermometer, dropping funnel and stirrer in sequence according to the ratio, the reaction was protected by nitrogen for 8h; the temperature was increased to 180 ℃, vacuum distillation to remove low-boiling substances to obtain hydrogen-terminated silicone oil; add hydrogen-terminated silicone oil, allyl glycidyl ether, toluene and chloroplatinic acid into the reactor; increase the temperature to 80 ℃, nitrogen protection reaction 10h, vacuum distillation The solvent is removed to obtain epoxy-terminated silicone oi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com