Block polymer, preparation method thereof and electrically active hydrogel

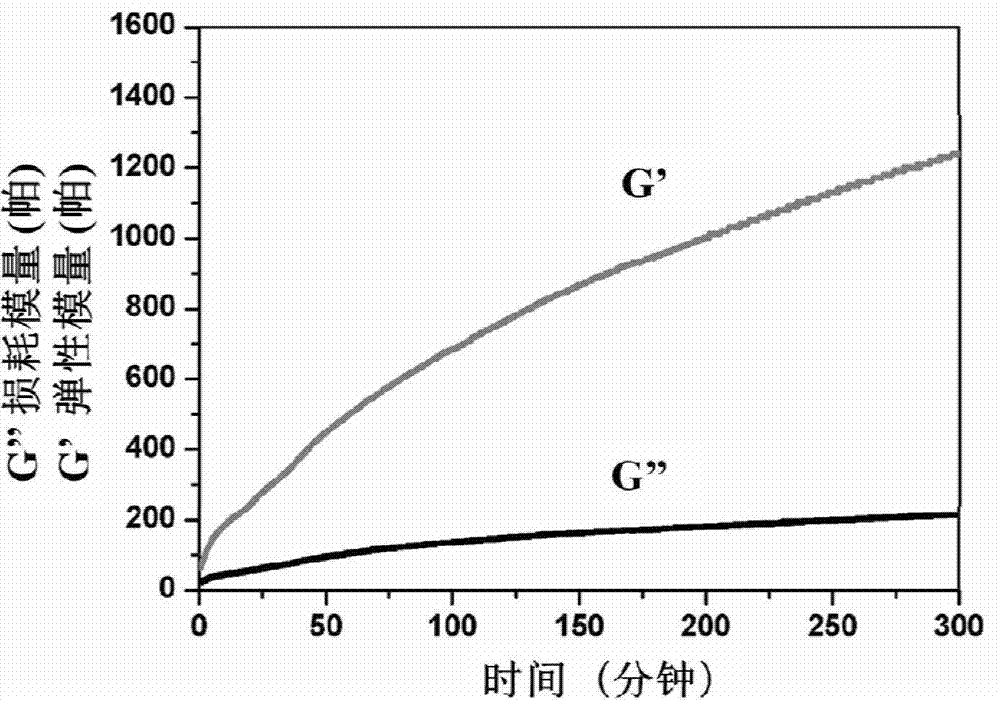

A block copolymer, electroactive technology, applied in electrodes, electrotherapy, adhesives, etc., can solve the problem that injectable hydrogels do not have electroactivity, and achieve good electrochemical response characteristics and good water solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The present invention also provides a kind of preparation method of block copolymer, comprises the following steps:

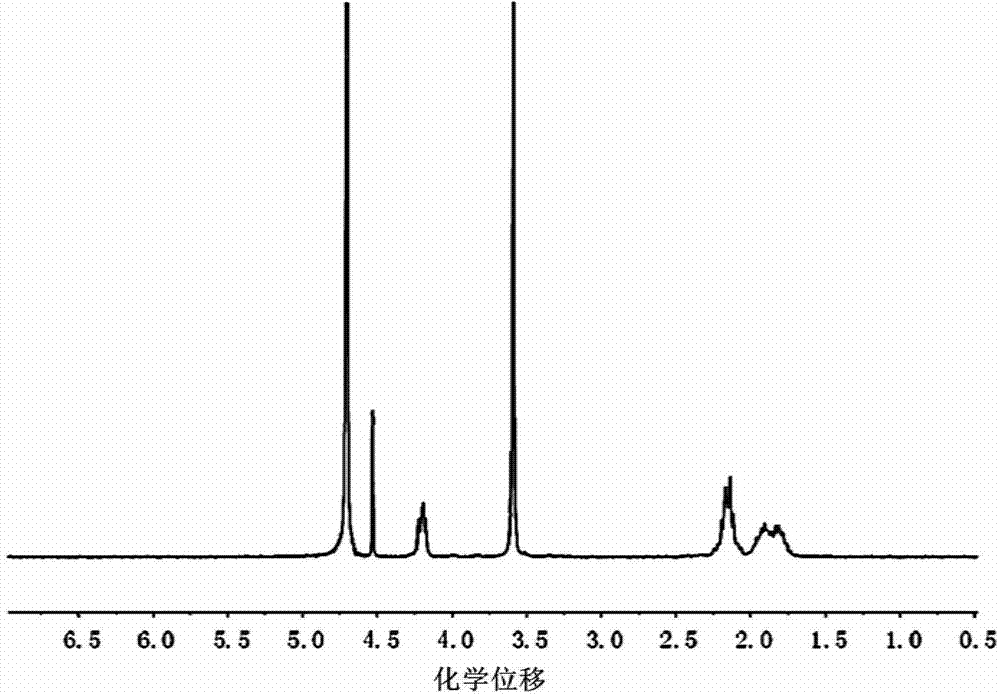

[0057] A) Mix terminal aminated polyethylene glycol monomethyl ether or terminal aminated polyethylene glycol with benzyl glutamate-N-carboxylic acid anhydride or benzyloxycarbonyl-lysine-N-carboxylic acid anhydride to carry out Ring-opening polymerization, followed by deprotection to obtain a polyglutamic acid block copolymer intermediate or a polylysine block copolymer intermediate;

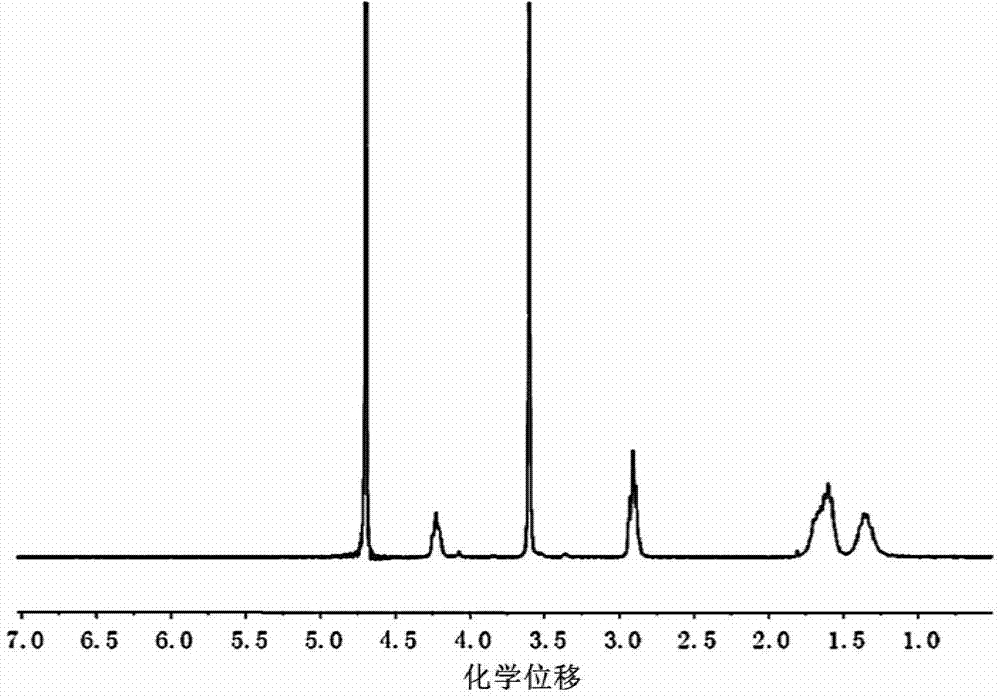

[0058] B) Mix the polyglutamic acid block copolymer intermediate obtained in step A) with a coupling reagent and a compound having the structure of formula (Ⅴ) to undergo a condensation reaction to obtain a polyglutamic acid block copolymer; ) The obtained polylysine block copolymer intermediate is mixed with a coupling reagent and a compound having the structure of formula (VI), and a condensation reaction occurs to obtain a polylysine block copolymer;

[0059]

[00...

Embodiment 1~3

[0142] First, 1 g of polyethylene glycol monomethyl ether with a number average molecular weight of 1000, 10000, and 20000 and 5 mL of toluene were azeotroped to remove water at 140 ° C, and the toluene was evaporated under reduced pressure to dissolve polyethylene glycol monomethyl ether with 10 mL of dichloromethane. ether to obtain a polyethylene glycol monomethyl ether solution, and then add triethylamine to the polyethylene glycol monomethyl ether solution at 0°C under anhydrous conditions according to the ratio in Table 1, and add methanesulfonyl chloride dropwise, After the dropwise addition, react at 0°C for 2 hours, then stir at room temperature for 24 hours, filter to remove the precipitate after the reaction, settle the filtrate with ether, filter to obtain a solid, and vacuum dry at room temperature for 24 hours to obtain polyethylene glycol methylsulfonate methyl ether ester. Table 1 shows the proportions of polyethylene glycol monomethyl ether, triethylamine and ...

Embodiment 4~6

[0147] First, 1 g of polyethylene glycol with a number average molecular weight of 1000, 10000, and 20000 and 5 mL of toluene were azeotroped to remove water at 140 ° C, and the toluene was evaporated under reduced pressure. After the toluene was evaporated, polyethylene glycol was dissolved in 10 mL of dichloromethane to obtain polyethylene glycol. solution, and then according to the ratio in Table 2, triethylamine was added to the polyethylene glycol solution at 0°C under anhydrous conditions, and methanesulfonyl chloride was added dropwise. After the dropwise addition, the reaction was carried out at 0°C for 2h Then the reaction was stirred at room temperature for 24 hours. After the reaction was completed, the precipitate was removed by filtration. The filtrate was settled with ether, and the solid was obtained by filtration. After vacuum drying at room temperature for 24 hours, polyethylene glycol methanesulfonate was obtained respectively. Table 2 shows the proportions of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com