Device and method for measuring thermal distortion of polarized beam splitter mirror

A polarization beam splitter and measuring device technology, which is applied in the direction of testing optical performance, etc., can solve the problems of not considering the influence of laser interferometry accuracy, difficulty in obtaining the absolute size distribution of deformation, and measuring wavefront thermal distortion of polarization beam splitters. , to achieve the effect of simple structure, easy construction and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

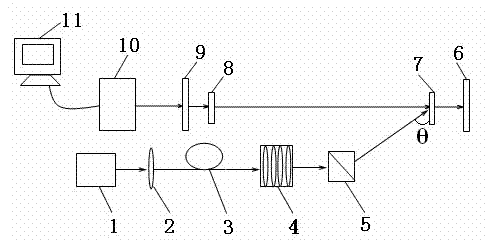

[0028] Below, in conjunction with accompanying drawing, the measuring device and measuring method of thermal distortion of polarizing beam splitter of the present invention are further described:

[0029] like figure 1 As shown, a measuring device for thermal distortion of a polarization beam splitter includes a solid-state laser 1 and a focusing lens 2 arranged outside the measurement room, an optical fiber shaping lens group 4, a beam splitter prism 5, a transmission plane mirror 6, and a polarization beam splitter installed inside the measurement room. 7. A zero-degree color filter 8, an attenuation filter 9, a Fizeau interferometer 10, a computer 11 connected to the Fizeau interferometer 10, and an energy fiber 3 extending from the measurement room to the outside.

[0030] The laser light emitted by the solid-state laser 1 is coupled to the energy fiber 3 through the focusing lens 2, and then enters the measurement room through the transmission of the energy fiber 3, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com