Surface modification sulfydryl magnetic nanometer material as well as preparation method and application of surface modification sulfydryl magnetic nanometer material

A magnetic nanometer and surface modification technology, which is applied to the magnetism of inorganic materials, chemical instruments and methods, and other chemical processes, can solve the problems of few surface active sites, low adsorption capacity, time-consuming, etc., and achieve easy surface modification. Sensitive surface area and good solution dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

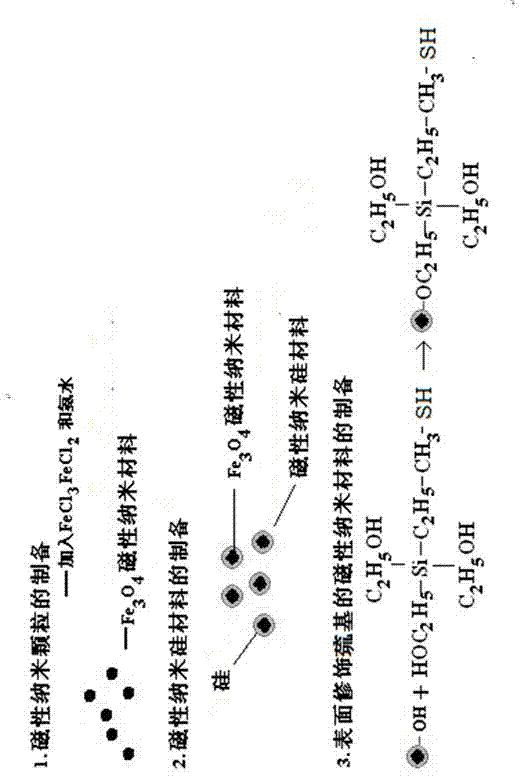

[0025] Example 1 Synthesis of magnetic nanomaterials with surface-modified mercapto groups

[0026] The synthesis of surface-modified magnetic nanomaterials with mercapto groups is divided into three steps.

[0027] (1) Synthesis of magnetic nanoparticles of ferric oxide by co-precipitation method: 10 g of ferric chloride and 4 g of ferrous chloride were dissolved in 100 mL of distilled water, stirred by a mechanical stirrer, and heated to 70 °C under nitrogen protection. ℃. Then add 10 mL of 10% NH 3 ·H2O, the color of the solution changes from orange red to black immediately. After cooling down to room temperature, the obtained nanoparticles were washed with twice distilled water and 0.02 mol L -1 washed several times with NaCl, and finally stored in distilled water.

[0028] (2) Put the magnetic nanoparticles of Fe3O4 synthesized in step (1) into a 250 mL three-necked flask, add 60 mL of 5% (V / V) TEOS and 60 mL of glycerine, and dissolve the The pH of the mixture was a...

Embodiment example 2

[0030] Example 2 Synthesis of magnetic nanomaterials with surface-modified mercapto groups

[0031] The synthesis of surface-modified magnetic nanomaterials with mercapto groups is divided into three steps.

[0032] (1) Synthesis of magnetic nanoparticles of ferric oxide by co-precipitation method: 12 g of ferric chloride and 6 g of ferrous chloride were dissolved in 200 mL of distilled water, stirred by a mechanical stirrer, and heated to 100 °C under nitrogen protection. ℃. Then add 20 mL of 30% NH 3 ·H2O, the color of the solution changes from orange red to black immediately. After cooling down to room temperature, the obtained nanoparticles were washed with twice distilled water and 0.04 mol L -1 washed several times with NaCl, and finally stored in distilled water.

[0033] (2) Put the magnetic nanoparticles of Fe3O4 synthesized in step (1) into a 250 mL three-neck flask, add 80 mL of 10% (V / V) TEOS and 80 mL of glycerine, and dissolve the The pH of the mixture was a...

Embodiment example 3

[0035] Example 3 Synthesis of magnetic nanomaterials with surface-modified mercapto groups

[0036] The synthesis of surface-modified magnetic nanomaterials with mercapto groups is divided into three steps.

[0037] (1) Synthesis of magnetic nanoparticles of ferric oxide by co-precipitation method: 12 g of ferric chloride and 5 g of ferrous chloride were dissolved in 150 mL of distilled water, stirred by a mechanical stirrer, and heated to 90 °C under nitrogen protection. ℃. Then add 20 mL of 30% NH 3 ·H2O, the color of the solution changes from orange red to black immediately. After cooling down to room temperature, the obtained nanoparticles were washed with twice distilled water and 0.03 mol L -1 washed several times with NaCl, and finally stored in distilled water.

[0038] (2) Put the magnetic nanoparticles of Fe3O4 synthesized in step (1) into a 250 mL three-neck flask, add 80 mL of 10% (V / V) TEOS and 80 mL of glycerine, and dissolve the The pH of the mixture was adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com