Purging agent and purging method using same

A cleaning agent and metal technology, applied in the field of cleaning agents, can solve problems such as cleaning performance decline, thermal deterioration, and product streaks, and achieve high-efficiency results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

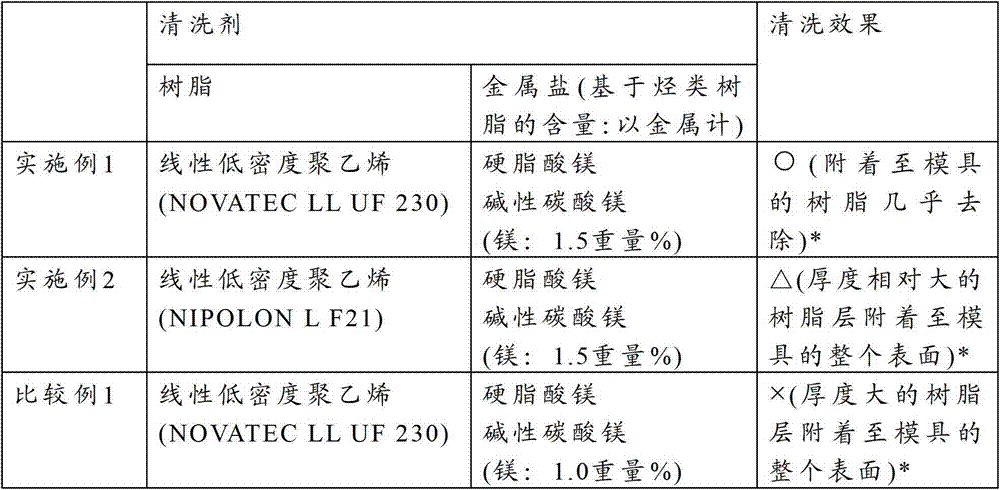

Embodiment 1

[0106] 90 parts of linear low-density polyethylene (NOVATEC LL UF230, manufactured by Japan Polyethylene Corporation, MFR: 1.0 g / 10 min (190°C, 2,160 g load), density: 0.921 g / cm 3 , number average molecular weight (polystyrene benchmark): 3.2×10 4 , dispersion degree (Mw / Mn): 3.9) was used as a cleaning agent, and 5 parts of magnesium stearate (manufactured by NOF Corporation, melting point: 125° C.) and 5 parts of basic magnesium carbonate (manufactured by Konoshima Chemical Co., Ltd., GOLD STAR) were used as metal salts and these were dry blended. The content of the metal salt in the obtained cleaning agent was 10% by weight, and the content of the metal salt was 1.5% by weight based on the metal based on the hydrocarbon resin.

[0107] The dry-blended product was melt-kneaded and shaped into pellets using a twin-screw extruder under the following conditions.

[0108] Screw diameter: 30mm

[0109] Extruder temperature: Cl / C2 / C3 / C4 / C5 / C6 / C7 / H / D=80 / 100 / 210 / 220 / 220 / 220 / 230 / ...

Embodiment 2

[0131] Except for the use of NIPOLON L F21, manufactured by Tosoh Corporation (MFR: 1.1g / 10min (190°C, load 2,160g), density: 0.92g / cm 3 , number average molecular weight (polystyrene benchmark); 2.0×10 4 , Dispersion (Mw / Mn): 5.7) Except for linear low-density polyethylene, an experiment was performed in the same manner as in Example 1, and the same evaluation as in Example 1 was performed.

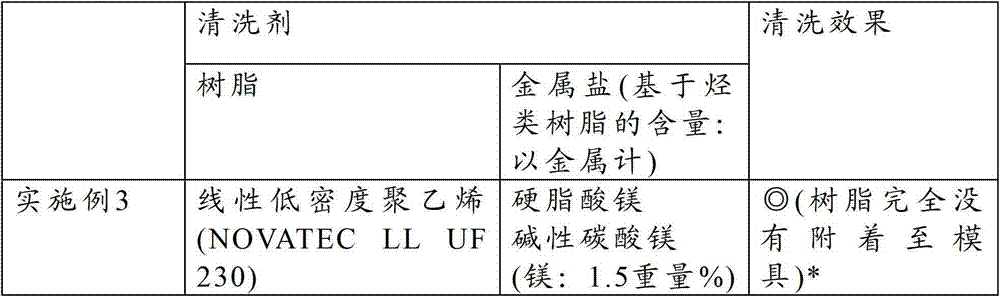

Embodiment 3

[0140]The cleaning agent obtained in Example 1 was used, and the following evaluations were performed.

[0141]

[0142] The following resin composition was prepared as a model composition of a recycled resin composition of a multilayer structure.

[0143] Using a single-screw extruder under the same conditions as in Example 1, the following resin composition was discharged for 30 minutes while being fed, and allowed to stand for 2 hours while being heated, and reproduced after long-term production of the resin composition status.

[0144]

[0145] Polypropylene (NOVATEC PP FX4G, manufactured by Nippon Polypropylene Corporation) 85 parts

[0146] Binder resin (MODIC-AP P604V, manufactured by Mitsubishi Chemical Corporation) 5 parts

[0147] Saponified ethylene-vinyl acetate copolymer 10 parts

[0148] (Ethylene content: 29 mol%, saponification degree: 99.8 mol%, MFR: 3.4g / 10min (210°C, 2160g load)

[0149]

[0150] Thereafter, the mold cleaning agent was supplied ove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com