Cadmium sulfide photocatalyst with high photocatalytic activity and preparation method thereof

A technology of photocatalytic activity and photocatalysis, which is applied in the field of photocatalysis, can solve the problems of low photocatalytic activity, and achieve the effects of low preparation cost, simple and easy preparation method, and no pollution in the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

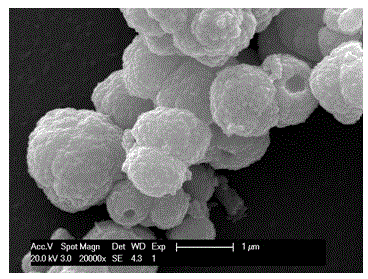

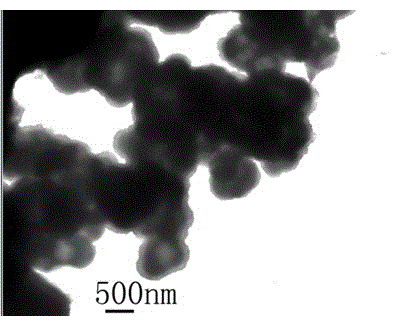

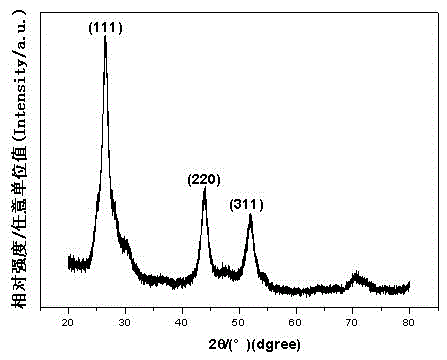

[0026] A higher cadmium cadmium cadmium catalyst with a higher light catalytic activity is a hollow micron ball structure. Among them, sulfur and cadmium are calculated, that is, sulfur: cadmium: 1: 1.

[0027] The preparation method of a higher cadmium cadmium sulfide light catalyst with higher light catalysis above includes the following steps:

[0028] 0.1molch 3 Nsch 3 And 0.1molcd (NO 3 Cure 2 · 4H 2 O dissolved in 40ml ethanol. After stirring for 2h, the powder is completely dissolved and the transfer is turned into a high -pressure kettle with a volume of 50ml to seal;

[0029] Subsequently, the reaction solution was heated to 150 ° C, the constant temperature was 24h, and after the temperature was naturally cooled to the room temperature, the yellow and the water -free ethanol were washed yellow to precipitate it to the neutrality of the outflow liquid;

[0030] Finally, it was dried in a vacuum at 80 ° C, that is, the cadmium sulfide catalyst with a higher catalytic activ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com