Method and device for fast cultivation of anaerobic granular sludge for treating swine wastewater

An anaerobic granular sludge and anaerobic culture technology, which is applied in the field of anaerobic granular sludge rapid culture method and device field, can solve the problems of increasing the complexity of microbial composition identification, large influence of granular sludge activity and high technical requirements, To achieve the effect of short culture period, reasonable structure and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

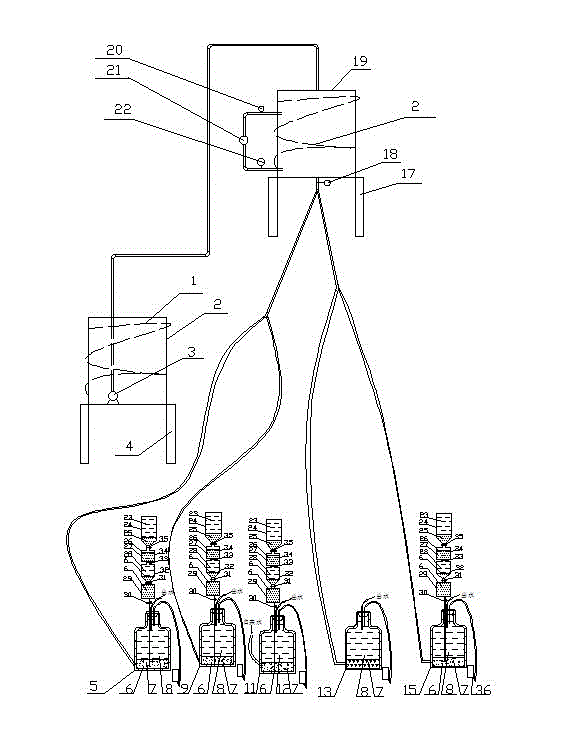

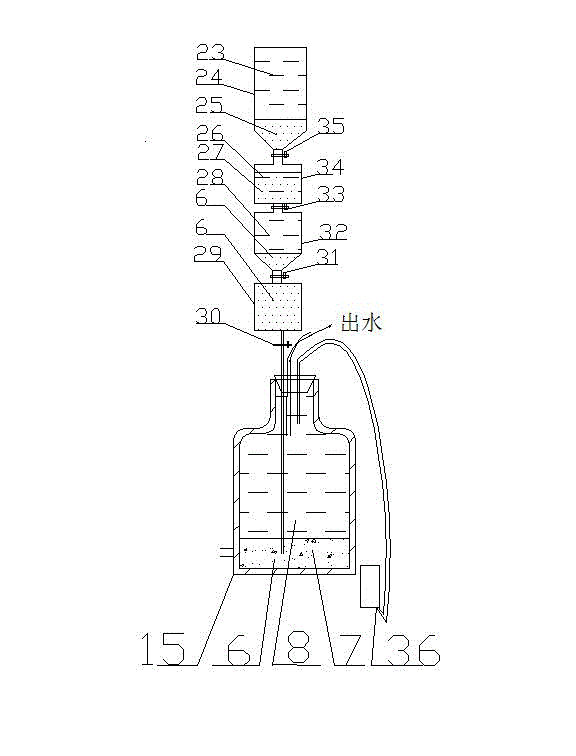

[0025] The present invention will be further described below using the accompanying drawings and examples.

[0026] refer to figure 1 and 2 , the volume of the anaerobic granular sludge rapid cultivation device for treating pig wastewater of the present invention is 20 liters, the volume of the inoculated sludge 7 is 2 liters, and the addition of the sludge acclimation stage, the granular sludge formation stage and the granular sludge maturity stage is completed The regenerated strong acid type ion exchange resin 6 has a volume of 40 milliliters, and the deactivated cation exchange resin 25 with a particle diameter of 0.612 mm is completely soaked in 4 liters of sodium hydroxide solution 23 of 3.5% for 6 hours by regulating The fourth separation valve 35 separates the deactivated cation exchange resin 25 at the bottom of the sodium hydroxide storage tank 24 after soaking into the distilled water storage tank 34, and washes the ion exchange resin to neutrality with 4 liters of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com