Preparation method of fluoroacetate

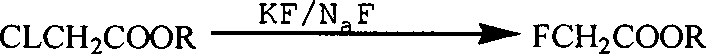

A technology of fluoroacetate and chloroacetate, which is applied in the preparation of fluoroacetate and the preparation of fine chemical products, and can solve the problems of low efficiency of fluoroacetate, low activity of fluorinated reagents, and low utilization rate of equipment, etc. problems, achieve high conversion efficiency, simple post-processing procedures, and save materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation of embodiment 1 potassium fluoride solid dispersion:

[0029] (1), add 1000g of water to the container, under stirring, add 600g of potassium fluoride to the water, stir until completely dissolved;

[0030] (2), under stirring, add micropowder silica gel 60g in the aqueous solution of potassium fluoride, continue to stir for 45 minutes;

[0031] (3) Remove moisture by rotary evaporation, and dry to obtain 661.5 g of a solid dispersion of potassium fluoride.

[0032] After testing, the potassium fluoride content in the solid dispersion is 89.7%, the moisture content is 0.12%, and the specific surface area is 165m 2 / g.

Embodiment 2

[0033] The preparation of embodiment 2 ethyl fluoroacetates:

[0034] Add 122 g of ethyl chloroacetate to the container, add 65 g of potassium fluoride solid dispersion under stirring, react at 20° C. for 3 hours, and separate to obtain 103 g of ethyl fluoroacetate with a yield of 99.1% and a purity of 99.7%.

Embodiment 3

[0035] The preparation of embodiment 3 ethyl fluoroacetates:

[0036] Add 122 g of ethyl chloroacetate to the container, add 65 g of potassium fluoride solid dispersion under stirring, react at 25° C. for 5 hours, and separate to obtain 100 g of ethyl fluoroacetate with a yield of 98.4% and a purity of 99.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com