Refining method of crude epalrestat product

A technology of epalrestat and refining method, which is applied in the field of refining epalrestat crude product and medicine purification, can solve the problems such as inability to obtain high-purity epalrestat, and achieve simple operation, high yield and good reaction conditions mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

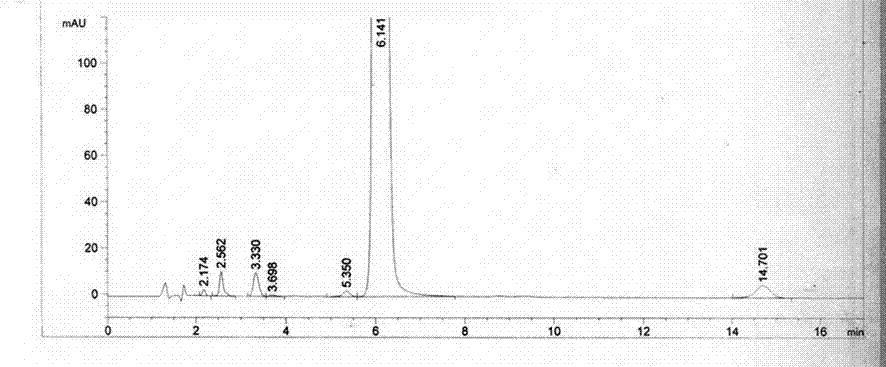

Image

Examples

Embodiment 1

[0031] The refining method of epalrestat crude product of the present invention, the detailed steps of this refining method are as follows:

[0032] a. One-time refining: first dissolve 10 g of epalrestat crude product in 30 ml of solvent tetrahydrofuran, heat to 55-65 °C to completely dissolve epalrestat crude product, stop heating after complete dissolution, and then slowly add solvent isopropyl ether 70 ml, After adding, a small amount of red solid is precipitated. Continue to heat to 55-65 ° C to completely dissolve the red solid, then stop heating, naturally cool and crystallize for 5 hours, and filter after crystallizing. After filtering, the wet product of epalrestat is obtained. The obtained epalrestat wet product was dried, the drying temperature was 100°C, and the drying time was 1 h, and after drying, 8.0 g of epalrestat after primary purification was obtained, and the yield was 80.0%;

[0033] b. Secondary refining:

[0034] Add 8.0 g of epalrestat after initial p...

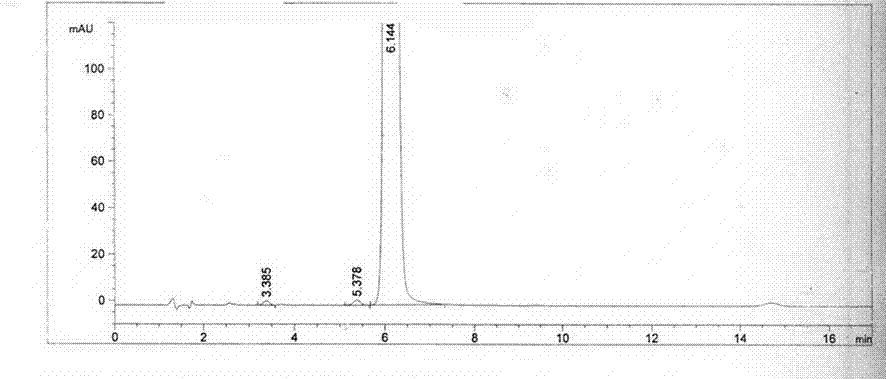

Embodiment 2

[0036] The refining method of epalrestat crude product of the present invention, the detailed steps of this refining method are as follows:

[0037] a. One-time refining: first, dissolve 10 g of epalrestat crude product in 40 ml of solvent tetrahydrofuran, heat to 50-55 °C to completely dissolve epalrestat crude product, stop heating after complete dissolution, and then slowly add solvent isopropyl ether 80 ml, After adding, a small amount of red solid is precipitated. Continue to heat to 50-55°C to completely dissolve the red solid, then stop heating, naturally cool and crystallize for 5.5 hours, and filter after crystallizing. The obtained wet epalrestat product was dried at a drying temperature of 90° C. and a drying time of 2 h. After drying, 8.1 g of epalrestat after primary purification was obtained, and the yield was 81.0%;

[0038] b. Secondary refining:

[0039] Add 8.1 g of epalrestat after initial purification in step a to 32.4 ml of solvent tetrahydrofuran, heat t...

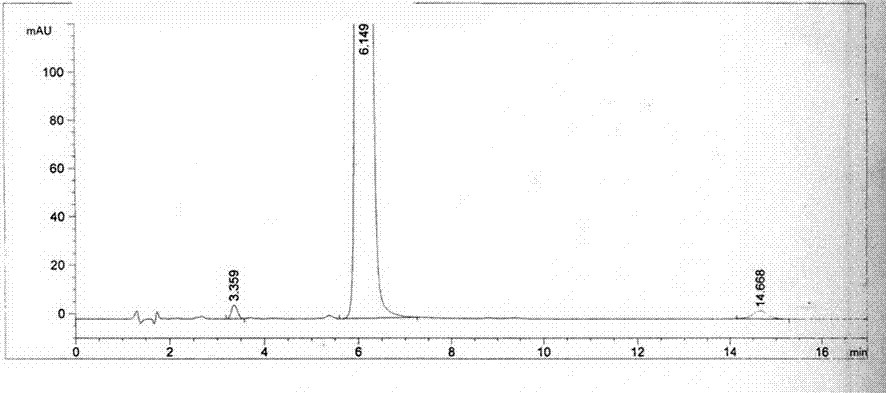

Embodiment 3

[0041] The refining method of epalrestat crude product of the present invention, the detailed steps of this refining method are as follows:

[0042] a. One-time refining: first dissolve 10 g of epalrestat crude product in 20 ml of solvent tetrahydrofuran, heat to 65-70 ° C to completely dissolve epalrestat crude product, stop heating after complete dissolution, and then slowly add solvent isopropyl ether 60 ml, After adding, a small amount of red solid is precipitated. Continue to heat to 65-70 ° C to completely dissolve the red solid, then stop heating, naturally cool for crystallization for 6 hours, and filter after crystallization. After filtration, the wet product of epalrestat is obtained. The obtained epalrestat wet product was dried, the drying temperature was 120°C, and the drying time was 1 h. After drying, 8.22 g of epalrestat after primary purification was obtained, and the yield was 82.2%;

[0043] b. Secondary refining:

[0044]Add 8.22 g of epalrestat after init...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com