Wind power oil pumping system

A wind power and oil pumping technology, which is applied to wind turbines, wind turbine combinations, wind turbine components, etc., can solve the problems of high power consumption, non-compliance with energy conservation and environmental protection, and achieve low production costs, stable working performance, and continuous production. effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

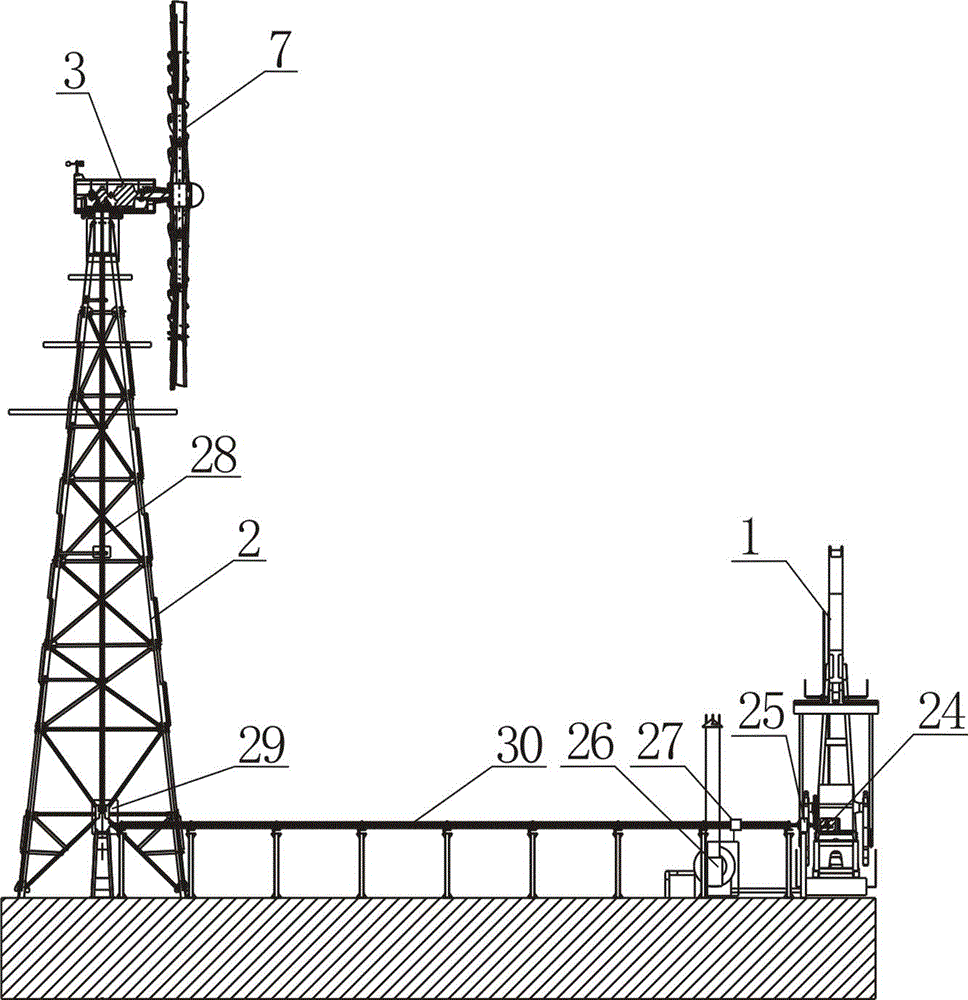

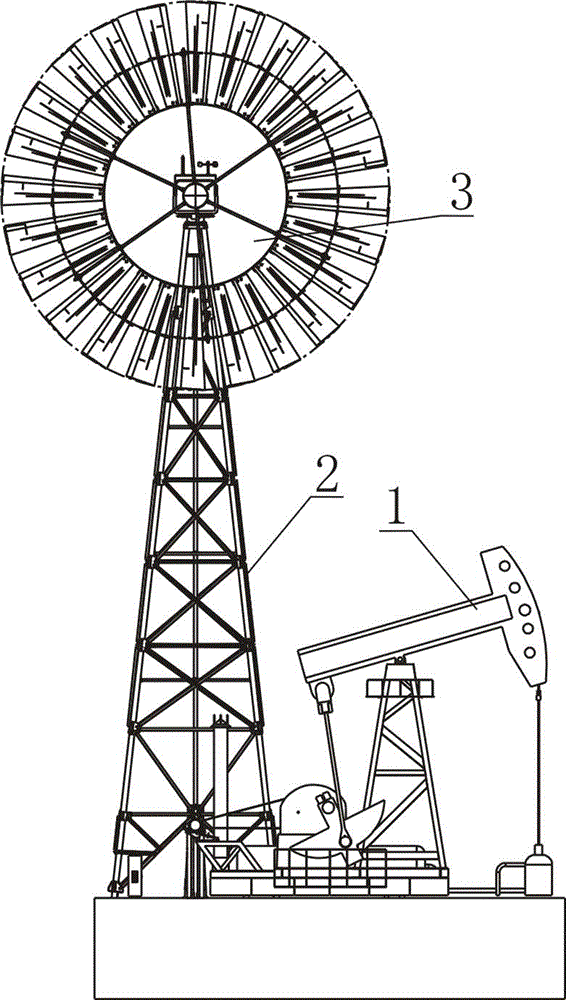

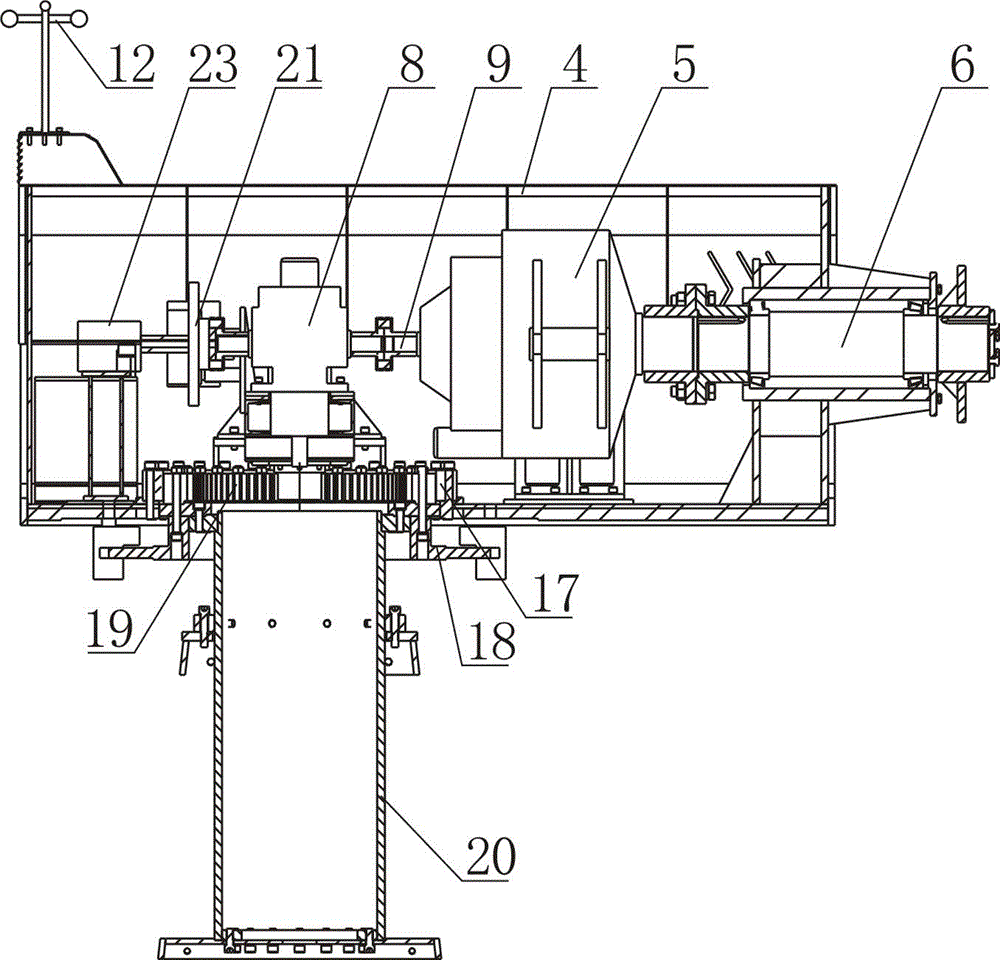

[0026] Such as figure 1 , 2 , shown in 3, a kind of wind power pumping system, comprises the oil field kowtow type pumping unit 1, also comprises support 2 and the wind energy harvesting device 3 that is located at the top of support 2, and described wind energy harvesting device 3 is mainly composed of chassis 4, speed increaser Case 5, power input shaft 6, wind impeller 7, steering output device 8 constitute, described speed-up box 5 and steering output device 8 are arranged in the chassis 4, and described steering output device 8 is arranged at the output shaft 9 of speed-up box Above, the steering output device 8 transmits power to the long-axis transmission mechanism, and one end of the power input shaft of the speed increasing box 5 passes through the casing 4, and the wind impeller 7 outside the casing 4 is arranged on the power input shaft 6 superior. What described speed-up box 5 adopted was star-shaped gear box. The long-axis transmission mechanism is composed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com