Audio and video signal transmission conduction wire

A technology for video signals and conductive wires, applied in conductors, circuits, conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problems of increasing the weight of the signal wire itself, poisonous workers, and high power consumption in the drawing and weaving process. Excellent conductive shielding effect, simple production equipment, and excellent shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

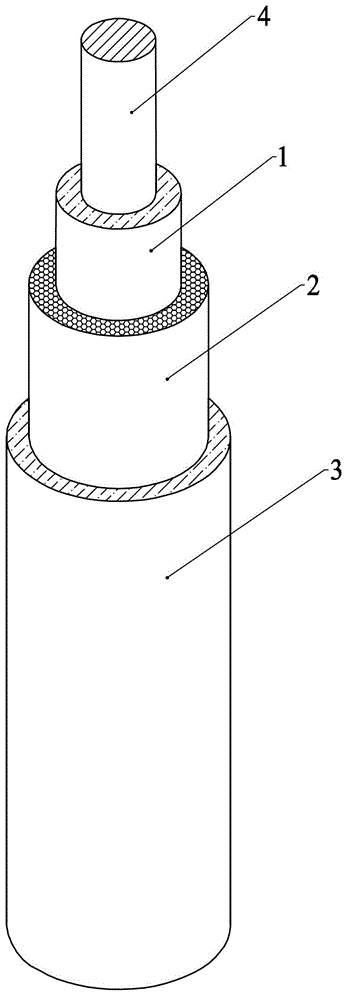

[0018] Embodiment: a kind of audio and video signal transmission conductive wire, comprises PE insulating layer 1, composite shielding layer 2 and PE outer sheath layer 3 that are covered by inner conductor 4 and from inner conductor from inside to outside layer, composite shielding layer is made of The following weight ratio is mixed with raw materials: polyethylene resin 75kg; PE toughening agent 15kg; nickel-plated, silver-plated conductive graphite powder 30kg; nano-shielding electromagnetic wave conductive heat insulation powder 15kg; tribasic lead sulfate 3kg; PE wax 2.5kg; PE modifier 2kg; Nali synthetic agent 20kg; PE insulating layer 1, composite shielding layer 2 and PE outer sheath layer 3 covered by the inner conductor 4 and the layer from the inner conductor from the inside to the outside are produced by multi-layer co-extrusion The process is one-time injection molding.

[0019] In the present invention, polyethylene, commercially available, referred to as PE, is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com