Disposal of organic waste

A technology of organic waste and organic fertilizer, applied in the treatment of bio-organic parts, preparation of organic fertilizer, organic fertilizer, etc., can solve the problems of little use, low value, low NPK value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

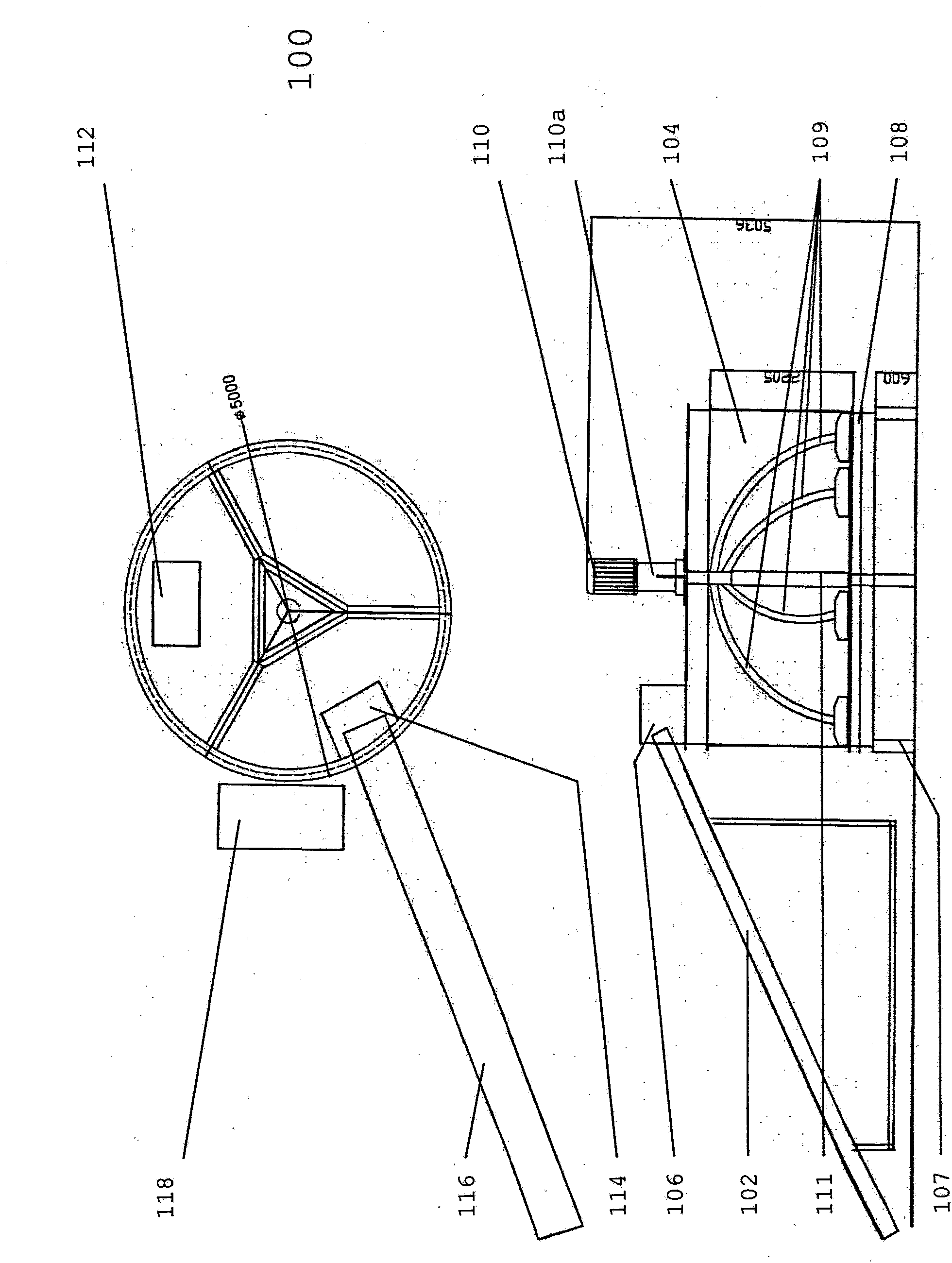

Image

Examples

Embodiment 1

[0112] Preparation of Organic Fertilizer from Raw Chicken Manure

[0113] Raw chicken manure, dead chickens and chicken feathers are mixed with sawdust, ash, rice bran, rice straw, wheat straw, used mushroom compost or corn cobs. Adjust the initial moisture content of the organic waste mixture to 35-60% (wt) in the first 6 hours, and then adjust and maintain it at 15-20% (wt). The mixture was heated to 100-150°C for the first 2h, after which the mixture was cooled to 50-65°C. To the mixture was added the microbial composition prepared above.

[0114] After the mixture was mixed with microorganisms for 2 hours, air was pumped in for 10 minutes, stopped for 20 minutes, and air was pumped in again for 10 minutes to maintain an aerobic environment. The process was allowed to run for 22h, then cooled. Air was pumped into the mixture for 3–4 hours, after which the treated organic waste was allowed to age for 2 days. NPK values and C:N ratios were determined using the analytica...

Embodiment 2

[0142] Preparation of organic fertilizer from empty fruit bunches

[0143] The 5-10mm threshed EFP pellets are mixed with chicken manure, dead chicken, goat manure, POME, EFB ash and / or ash. Adjust the initial moisture content of the organic waste mixture to 35-60% (wt) in the first 6 hours, and then adjust and maintain it at 15-20% (wt). The mixture was heated to 100-150°C for the first 2h, after which the mixture was cooled to 50-65°C. To the mixture was added the microbial composition prepared above.

[0144] After the mixture and microbial composition were mixed for 2 hours, air was pumped in for 10 minutes, stopped for 20 minutes, and air was pumped in again for 10 minutes to maintain an aerobic environment. The process was allowed to run for 22h, then cooled. Air was pumped into the mixture for 3-4 hours, after which the treated organic waste was allowed to age for 2 days. NPK values and C:N ratios were determined using the analytical methods listed above.

[0145...

Embodiment 3

[0171] Preparation of organic fertilizers from food waste sludge

[0172] Dividing food waste sludge and / or material collected at coarse mesh benches in food processing plants with rice husks, rice straw, wheat straw, corn cobs, coffee bean husks, oil palm EFB, olive husks, fruit peels, wood chips, discarded Vegetables, used mushroom compost, used orchid compost and / or cut flower mix. Adjust the initial moisture content of the organic waste mixture to 35-60% (wt) in the first 6 hours, and then adjust and maintain it at 15-20% (wt). The mixture was heated to 100-150°C for the first 2h, after which the mixture was cooled to 50-65°C. To the mixture was added the microbial composition prepared above.

[0173] After the mixture and microbial composition were mixed for 2 hours, air was pumped in for 10 minutes, stopped for 20 minutes, and air was pumped in again for 10 minutes to maintain an aerobic environment. The process was allowed to run for 22h, then cooled. Air was pumped...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com