X8R-type capacitor ceramic material with high dielectric constant and preparation method thereof

A capacitor ceramic, high dielectric constant technology, applied in the field of ceramic materials, can solve the problem that ceramic materials are not in a highly mature stage, and achieve the effect of high dielectric constant and improved temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

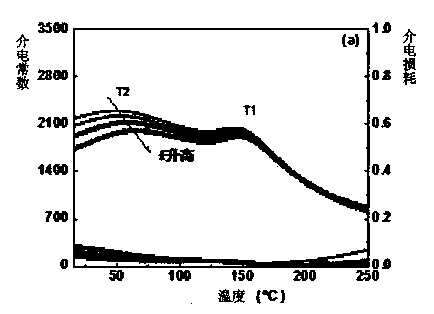

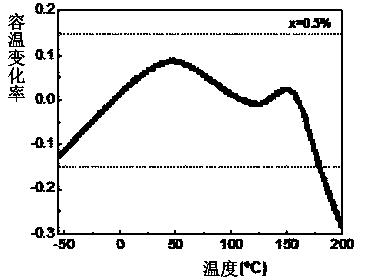

Examples

Embodiment 1

[0035] A high dielectric constant X8R type capacitor ceramic material is composed of a matrix component and a doping component, and the chemical formula of the matrix component is aBaTiO 3 -bNa 0.5 Bi 0.5 TiO 3 , a=0.92, b=0.08, the chemical formula of the doping component is cYb 2 o 3 -dMgO, c=0.015, d=0.005, the chemical expression of the high dielectric constant X8R capacitor ceramic material is 0.92BaTiO 3 -0.08Na 0.5 Bi 0.5 TiO 3 -0.015Yb 2 o 3 -0.005MgO.

[0036] The preparation method of above-mentioned high dielectric constant X8R type capacitor ceramic material, it comprises the following steps:

[0037] (1) According to the chemical expression of high dielectric constant X8R capacitor ceramic material 0.92BaTiO 3 -0.08Na 0.5 Bi 0.5 TiO 3 -0.015Yb 2 o 3 The stoichiometric ratio of metal atoms in -0.005MgO weighs the matrix component raw material BaTiO 3 、 Bi 2 o 3 、Na 2 CO 3 、TiO 2 and doping component raw material Yb 2 o 3 , MgO, standby;

[...

Embodiment 2

[0043] A high dielectric constant X8R type capacitor ceramic material is composed of a matrix component and a doping component, and the chemical formula of the matrix component is aBaTiO 3 -bNa 0.5 Bi 0.5 TiO 3 , a=0.92, b=0.08, the chemical formula of the doping component is cYb 2 o 3 -dMgO, c=0.015, d=0.01, the chemical expression of the high dielectric constant X8R capacitor ceramic material is 0.92BaTiO 3 -0.08Na 0.5 Bi 0.5 TiO 3 -0.015Yb 2 o 3 -0.01MgO.

[0044] The preparation method of above-mentioned high dielectric constant X8R type capacitor ceramic material, it comprises the following steps:

[0045] (1) According to the chemical expression of high dielectric constant X8R capacitor ceramic material 0.92BaTiO 3 -0.08Na 0.5 Bi 0.5 TiO 3 -0.015Yb 2 o 3 The stoichiometric ratio of metal atoms in -0.01MgO weighs the matrix component raw material BaTiO 3 、 Bi 2 o 3 、Na 2 CO 3 、TiO 2 and doping component raw material Yb 2 o 3 , MgO, standby;

[004...

Embodiment 3

[0051] A high dielectric constant X8R type capacitor ceramic material is composed of a matrix component and a doping component, and the chemical formula of the matrix component is aBaTiO 3 -bNa 0.5 Bi 0.5 TiO 3 , a=0.9, b=0.1, the chemical formula of the doping component is cYb 2 o 3 -dMgO, c=0.015, d=0.005, the chemical expression of the high dielectric constant X8R type capacitor ceramic material is 0.9BaTiO 3 -0.1Na 0.5 Bi 0.5 TiO 3 -0.015Yb 2 o 3 -0.005MgO.

[0052] The preparation method of above-mentioned high dielectric constant X8R type capacitor ceramic material, it comprises the following steps:

[0053] (1) According to the chemical expression of high dielectric constant X8R capacitor ceramic material 0.9BaTiO 3 -0.1Na 0.5 Bi 0.5 TiO 3 -0.015Yb 2 o 3 The stoichiometric ratio of metal atoms in -0.005MgO weighs the matrix component raw material BaTiO 3 、 Bi 2 o 3 、Na 2 CO 3 、TiO 2 and doping component raw material Yb 2 o 3 , MgO, standby;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com