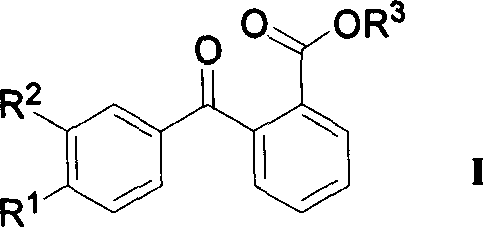

Photoinitiator for ultraviolet light curing agent and manufacturing method thereof

A manufacturing method and technology of photoinitiator, which are applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as inconsistent test results, and achieve the effects of simple manufacturing method, high yield and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

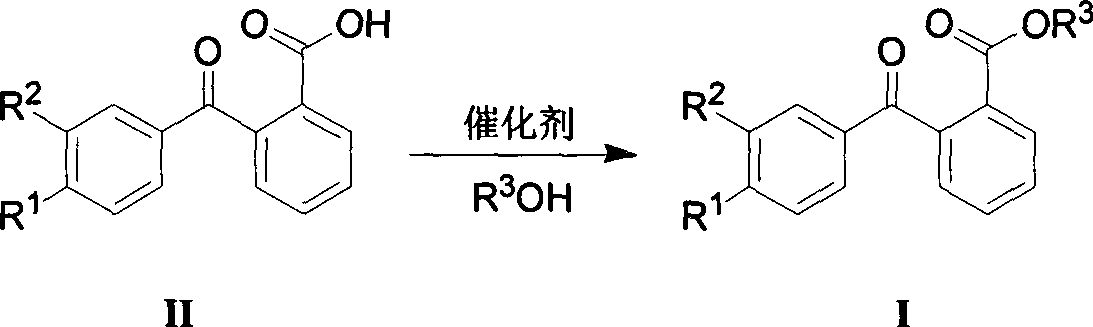

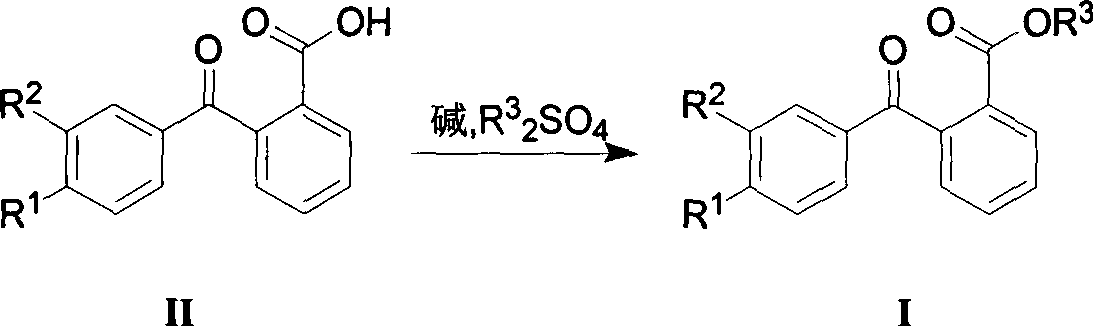

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: the manufacture of 2-(4'-methylbenzoyl) methyl benzoate (concentrated sulfuric acid method)

[0032] In a 250ml four-neck flask equipped with mechanical stirring, add 24.0g 2-(4'-methylbenzoyl)benzoic acid, 72ml toluene and 16.0g methanol, after stirring evenly, slowly add 5.0ml concentrated sulfuric acid dropwise, heat Reflux water separation, TLC or liquid phase monitoring reaction end point, the reaction is complete, cool to room temperature, slowly add 20ml of water dropwise to dilute, separate the lower aqueous phase and discard, and use 5% NaOH aqueous solution (pH about 8) and water respectively for the organic phase. Washed once, dried over anhydrous sodium sulfate, and desolvated under low pressure to obtain 24.0 g of light yellow oil, 21.0 g of white crystals recrystallized with 40 ml of methanol, the yield was 82.7%, and the liquid phase content was 99.0%.

Embodiment 2

[0033] Embodiment 2: the manufacture of 2-(4'-methylbenzoyl) methyl benzoate (SOCl 2 Law)

[0034] In a 250ml four-necked flask equipped with a mechanical stirrer, add 24.0g 2-(4'-methylbenzoyl)benzoic acid, 72ml toluene and 16.0g methanol, after stirring evenly, slowly add 17.8g dropwise under ice bath Thionyl chloride, heated to reflux for water separation, TLC or liquid phase monitoring reaction end point, reaction was complete, cooled to room temperature, slowly added dropwise to 20ml water for dilution, separated the lower aqueous phase and discarded, organic phase with 5% NaOH aqueous solution (pH About 8) was washed with water once, dried over anhydrous sodium sulfate, and desolvated under low pressure to obtain 24.2g of a light yellow oil, and 21.4g of white crystals recrystallized with 40ml of methanol, with a yield of 85.0% and a liquid phase content of 99.0%.

Embodiment 3

[0035] Embodiment 3: the manufacture of 2-(4'-methylbenzoyl) methyl benzoate (p-toluenesulfonic acid method)

[0036] In a 250ml four-neck flask equipped with mechanical stirring, add 24.0g 2-(4'-methylbenzoyl)benzoic acid, 72ml toluene and 16.0g methanol, after stirring evenly, add 5.0g p-toluenesulfonic acid, heat Reflux to separate water, TLC or liquid phase to monitor the reaction end point, the reaction is complete, cool to room temperature, let stand to separate layers, separate the lower layer of water and discard, the organic phase is washed with 80ml of 5% NaOH aqueous solution (pH about 8) and water Once, dried over anhydrous sodium sulfate and desolvated under low pressure to obtain 23.0 g of light yellow oil, 18.4 g of white crystals recrystallized with 20 ml of methanol, yield 72.7%, liquid phase content 99.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com