Method for directly synthesizing pure solid high-performance polycarboxylate water-reducer in one step

A pure solid, polycarboxylate technology, applied in the field of polycarboxylate high-performance water reducers, to achieve the effect of reducing process steps, reducing transportation costs, and reducing high-temperature energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

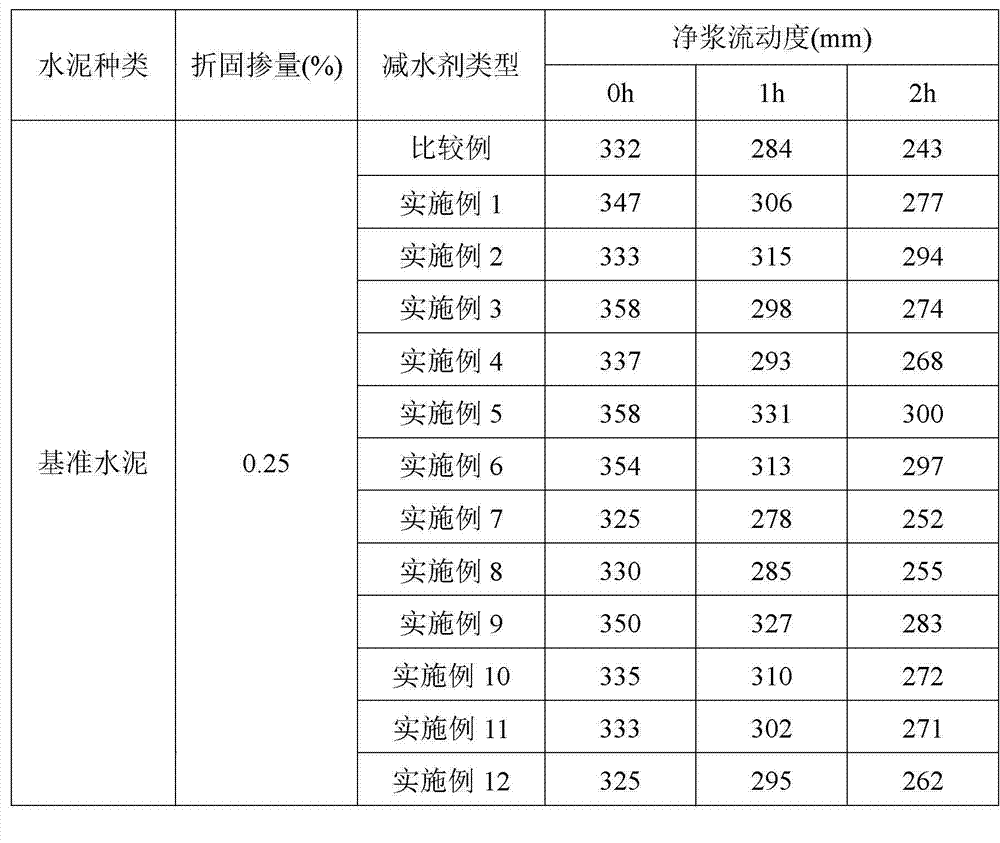

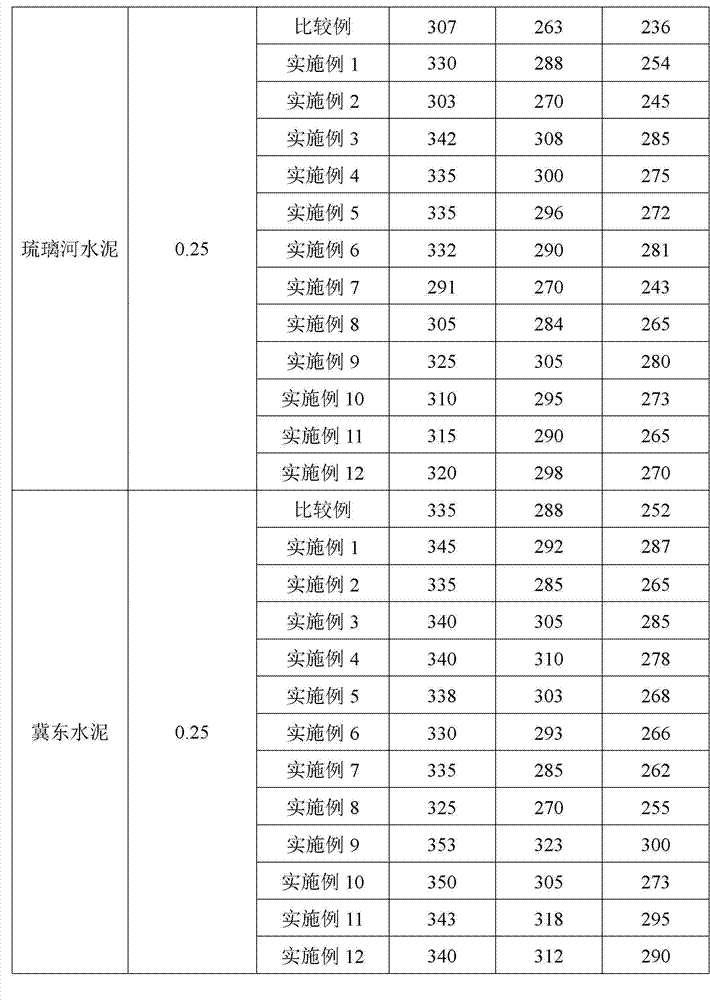

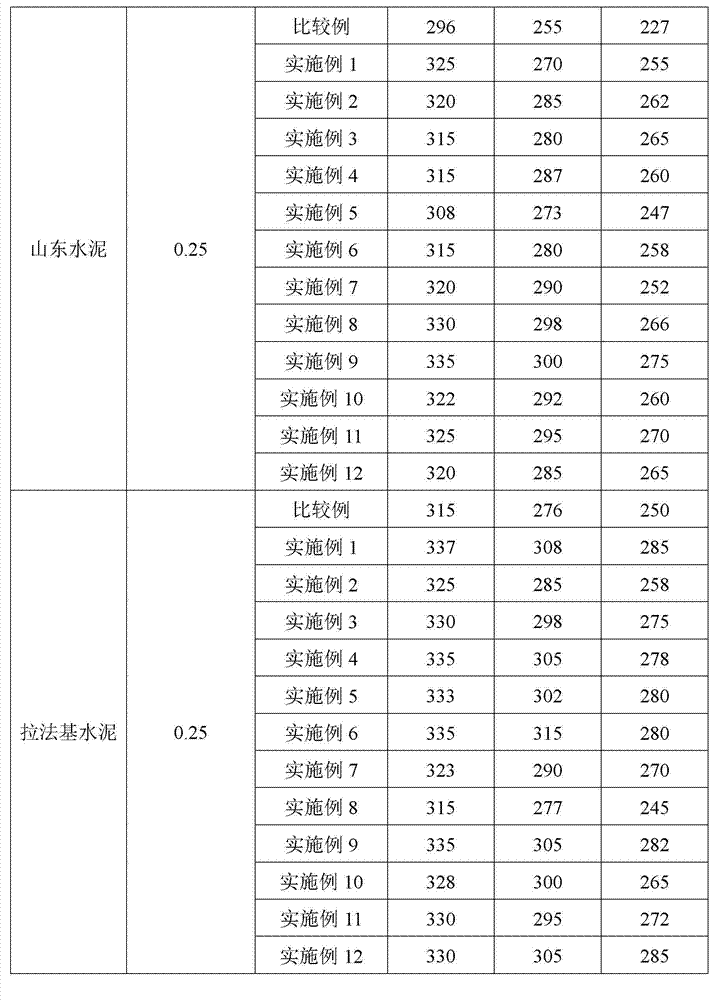

Examples

Embodiment 1

[0021]First, add 100g of allyl polyoxyethylene ether (molecular weight: 2000) into the reactor, raise the temperature to 50°C, and when the allyl polyoxyethylene ether is in liquid state, add 4.74g of methacrylic sulfonic acid into the reactor in turn Sodium, 21.62g of acrylic acid, 6.21g of azobisisoheptanonitrile, and the stirring time between each addition is 20 minutes, continue to heat up to 75°C for bulk polymerization, react for 6 hours, stop the reaction, cool to 25°C, and obtain The reaction product of 131.85g pure solid, finally add 307.65g water and dilute to obtain the polycarboxylate superplasticizer that concentration is 30%.

Embodiment 2

[0023] After the polycarboxylate superplasticizer with a concentration of 30% obtained in Example 1 was stored at 7°C for 40 days, its implementation effect was measured.

Embodiment 3

[0025] First, 96g of isobutenyl polyoxyethylene ether (molecular weight: 2400) was added to the reactor, and the temperature was raised to 70°C. When the isobutenyl polyoxyethylene ether was in liquid state, 3.18g of mercaptopropionic acid and 9.29g of formazan were sequentially added to the reactor. Acrylic acid, 0.48g dibenzoyl peroxide, and the stirring time between each addition is 5 minutes, continue to heat up to 95 ° C for bulk polymerization, react for 2.5 hours, stop the reaction, cool to 40 ° C, and obtain 108.95 g of pure Solid reaction product, finally add 163.43g water and dilute to obtain the polycarboxylate superplasticizer that concentration is 40%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com