Moisture-permeable and waterproof type no-yellowing polyurethane resin for shoe leather and preparation method

A polyurethane resin, moisture-permeable and waterproof technology, which is applied in the field of polyurethane resin and its preparation, can solve the problems of affecting product appearance and physical properties, yellowing and brittleness, lack of yellowing resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029]

[0030]

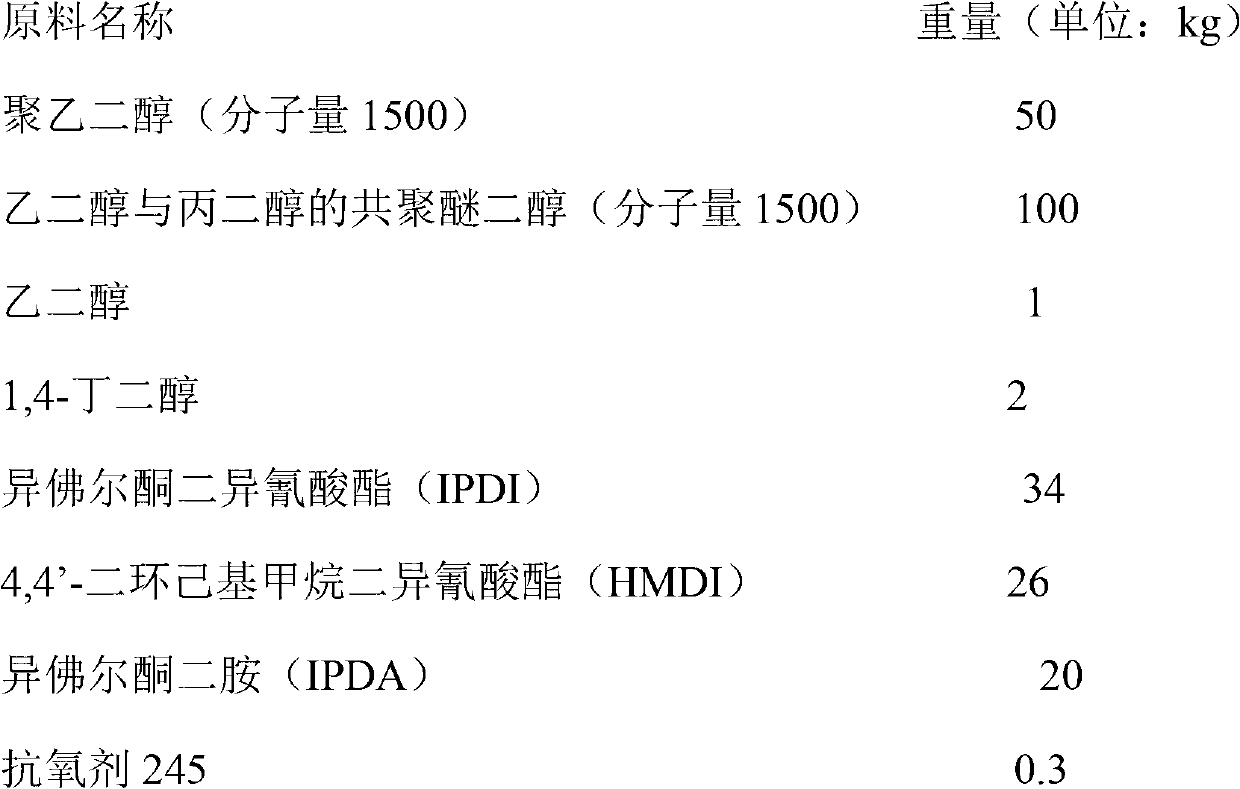

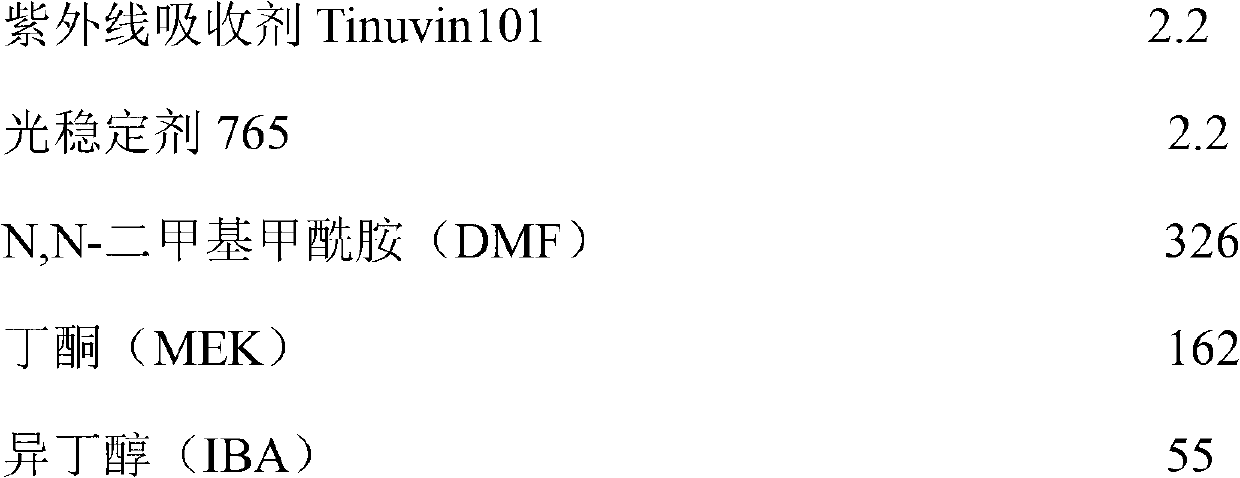

[0031] 50kg of polyethylene glycol, 100kg of copolyether glycol of ethylene glycol and propylene glycol, 1kg of ethylene glycol, 2kg of 1,4-butanediol, 34kg of isophorone diisocyanate (IPDI), 26kg 4,4'-dicyclohexylmethane diisocyanate (HMDI), 0.2kg of antioxidant 245, 1.4kg of UV absorber Tinuvin101, 1.4kg of light stabilizer 765, 0.2kg of anti-blocking agent and 150kg of N,N -Dimethylformamide (DMF) was put into the reaction kettle together, reacted at 90°C for 4 hours, measured the content of isocyanate group (-NCO) in the mixed liquid, after it dropped to the theoretical value, then added 150kg of N,N -Dilution with dimethylformamide (DMF), add 20kg of isophorone diamine (IPDA) dropwise, react at 30°C, add DMF and MEK to dilute continuously during the process, to reach the required viscosity, add the remaining MEK and IBA, Stir at 70°C for 2 hours. After detecting the presence of -NCO groups, add 0.1kg of antioxidant 245, 0.8kg of ultraviolet absorbe...

Embodiment 2

[0033]

[0034]

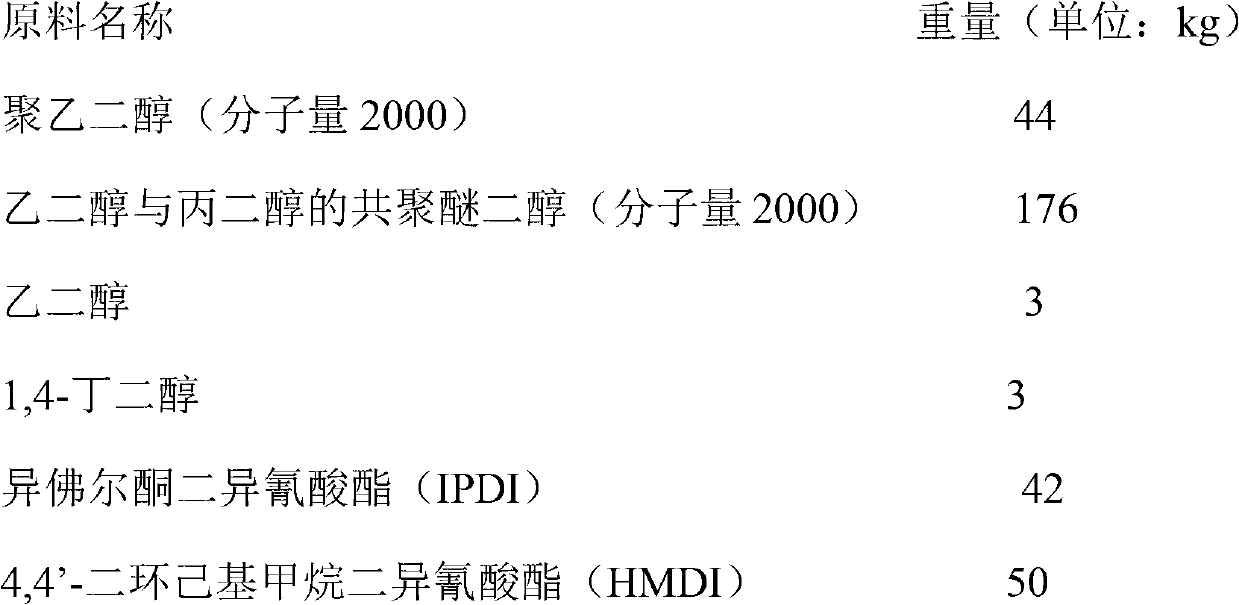

[0035] 44kg of polyethylene glycol, 176kg of copolyether glycol of ethylene glycol and propylene glycol, 3kg of ethylene glycol, 3kg of 1,4-butanediol, 42kg of isophorone diisocyanate (IPDI), 50kg 4,4'-dicyclohexylmethane diisocyanate (HMDI), 0.3kg of antioxidant 245, 3.5kg of UV absorber Tinuvin101, 3.5kg of light stabilizer 765, 0.3kg of anti-blocking agent and 175kg of N,N -Dimethylformamide (DMF) was put into the reaction kettle together, reacted at 10°C for 2 hours, measured the content of isocyanate group (-NCO) in the mixed solution, after it dropped to the theoretical value, then added 175kg of N,N -dilute with dimethylformamide (DMF), add 40kg of 4,4'-diaminodicyclohexylmethane (HMDA) dropwise, react at 50°C, add DMF and MEK continuously during the process to reach the required viscosity, add the remaining MEK and IBA were stirred at 80°C for 2 hours, and after no -NCO groups were detected, 0.2kg of antioxidant 245, 3.0kg of ultraviolet absorbe...

Embodiment 3

[0037]

[0038]

[0039]50kg of polyethylene glycol, 250kg of copolyether glycol of ethylene glycol and propylene glycol, 4kg of 1,4-butanediol, 4kg of neopentyl glycol, 94kg of isophorone diisocyanate (IPDI), 1.0kg of antioxidant 245, 5.5kg of UV absorber Tinuvin101, 5.5kg of light stabilizer 765, 1.0kg of anti-adhesive agent and 250kg of N,N-dimethylformamide (DMF) were put into the reaction kettle together. React at 90°C for 2 hours, measure the content of isocyanate group (-NCO) in the mixture, after it drops to the theoretical value, add 250kg of N,N-dimethylformamide (DMF) to dilute, add dropwise 30kg of 4 , 4'-Diaminodicyclohexylmethane (HMDA) and 20kg of isophoronediamine (IPDA) reacted at 30°C, during which DMF and MEK were continuously added to dilute to reach the required viscosity, and the remaining MEK and IBA were added , stirred at 70° C. for 2 hours, after measuring the presence of no -NCO group, added 0.5 kg of antioxidant 245, 3.0 kg of ultraviolet abso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydrostatic pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com